Wired tapping machine

A tapping machine and connection technology, which is applied in the field of tapping machines, can solve the problems of multi-manpower input and achieve the effects of improving production efficiency, facilitating tapping, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

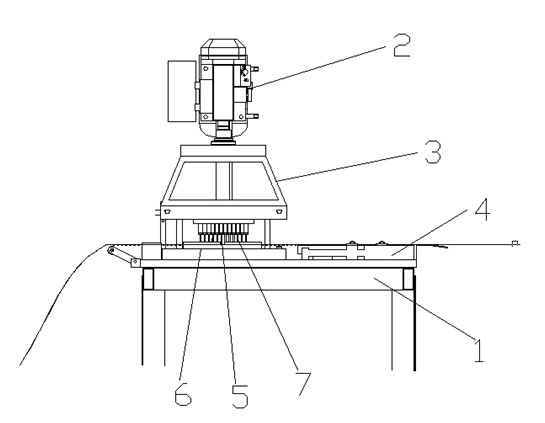

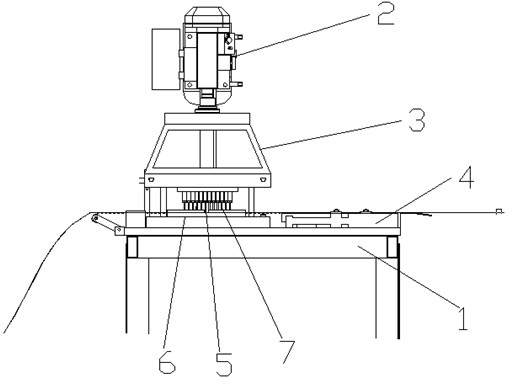

[0014] An in-line tapping machine, which includes a bracket 1, a tapping machine 2, a multi-axis device 3 and a feeder 4, based on the state of use, the multi-axis device is fixed on the bracket, and the tapping machine The tapping machine is fixed above the multi-axis device, and the multi-axis device is provided with several vertically downward tapping heads 5, and the tapping machine can just drive several vertical tapping heads 5 on the multi-axis device. The downward tapping head simultaneously performs downward tapping action; the feeder can just drive the material strip to be tapped to move in the horizontal direction. When in use, the feeder first sends the material tape to be tapped directly under the tapping head, and then starts the tapping machine to drive several tapping heads on the multi-axis device to perform tapping operations at the same time. After the tapping is completed, the feeder Then drive the material belt to move forward, and then the tapping machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com