Minitype magnetic field sensor based on nano particle magneto rheological elastomer film

A magnetorheological elastomer, magnetic field sensor technology, applied in the use of electromagnetic devices for magnetic field measurement, magnetic field size/direction and other directions, can solve problems such as consumption deformation or maintaining resonance, accuracy is easily affected by temperature, etc., to reduce power consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The manufacturing process of the new nanoparticle magnetorheological elastomer film:

[0018] (1) Preparation of PDMS-iron powder mixture

[0019] Polydimethylsiloxane (Polydimethylsiloxane, PDMS) is a new type of polymer material widely used in the field of micro-electromechanical. The material is a transparent elastomer at room temperature, has biocompatibility, chemical resistance, and good wear resistance. . The PDMS used to make the nanoparticle magnetorheological elastomer film is divided into two parts: silica gel and curing agent (Dow Corning SYLGARD 184). The production steps are as follows:

[0020] 1) Mix the silica gel and the curing agent in a weight ratio of 10:1, stir evenly, put the mixture into an ultrasonic oscillator and vibrate for 2 minutes to remove bubbles, and at the same time promote its further mixing.

[0021] 2) Mix the mixture obtained in step 1) with chloroform at a weight ratio of 1:1, stir well and shake again for 10 minutes to ensure t...

Embodiment 2

[0029] Because the elastic modulus E of the novel nanoparticle magnetorheological elastomer film will change under the condition of a field, the present invention utilizes this characteristic to make it.

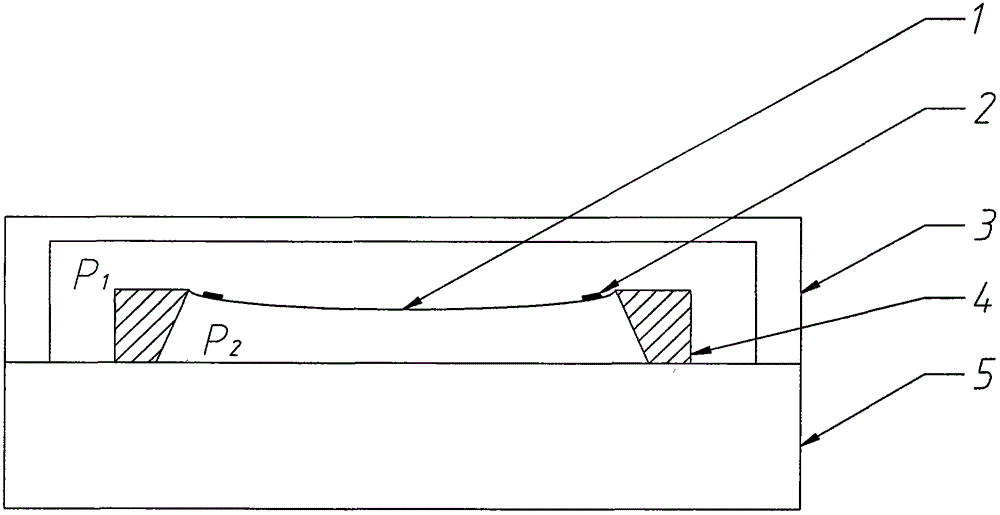

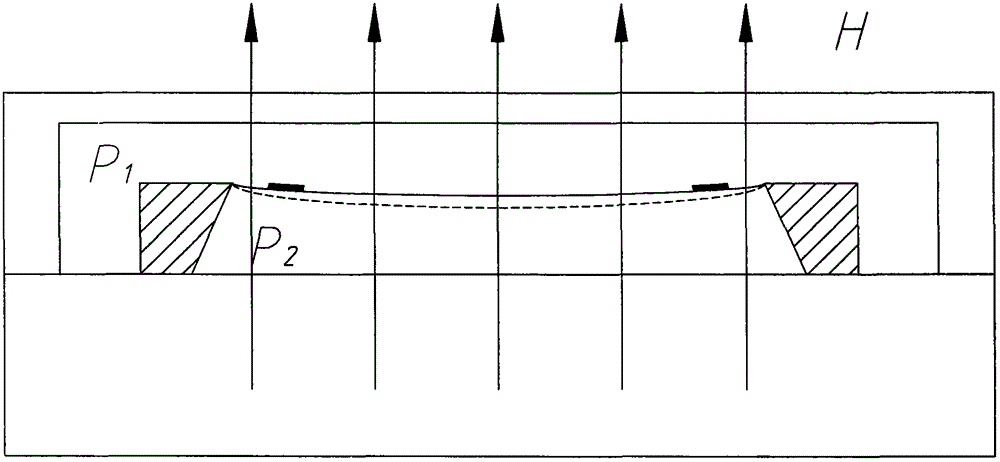

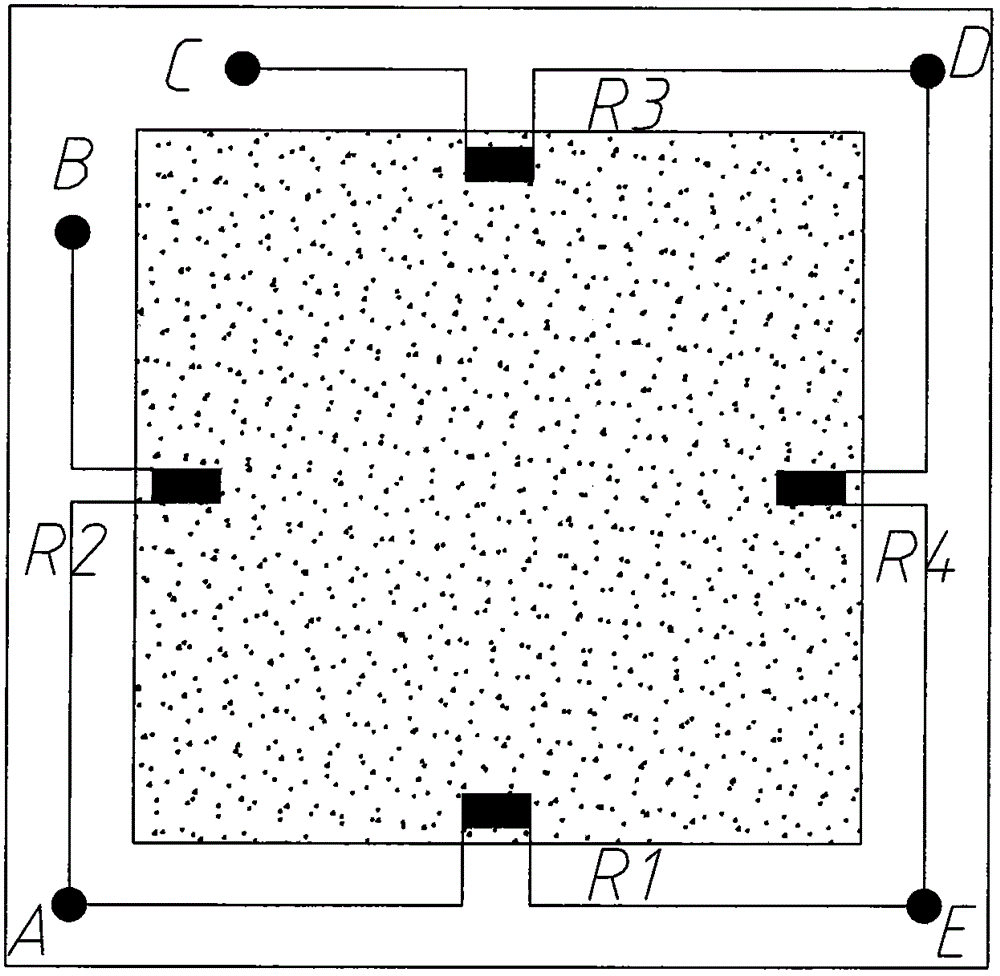

[0030] Such as figure 1 Shown is the cross-section of the initial state of the miniature magnetic field sensor of the present invention, and the overall structure of the miniature magnetic field sensor is as follows Figure 5 As shown, it includes a nanoparticle magnetorheological elastomer film 1 , four piezoresistors deposited on the nanoparticle magnetorheological elastomer film 1 , a glass cover 3 , a silicon substrate 4 and a glass substrate 5 . figure 1 Among them, P1 is atmospheric pressure, and P2 is vacuum, and the air pressure difference (the difference between P1 and P2) on both sides of the nanoparticle magnetorheological elastomer film 1 will cause the nanoparticle magnetorheological elastomer film 1 to bend and deform to the side where the air pressure is small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com