Roast-bending die for secondary forming of automobile glass

A secondary molding, automotive glass technology, applied in glass molding, glass remolding, glass production and other directions, can solve the problems of low automation of equipment, time-consuming and laborious reset operation, etc., to avoid manual manual operation and improve reset speed. , to achieve the effect of equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

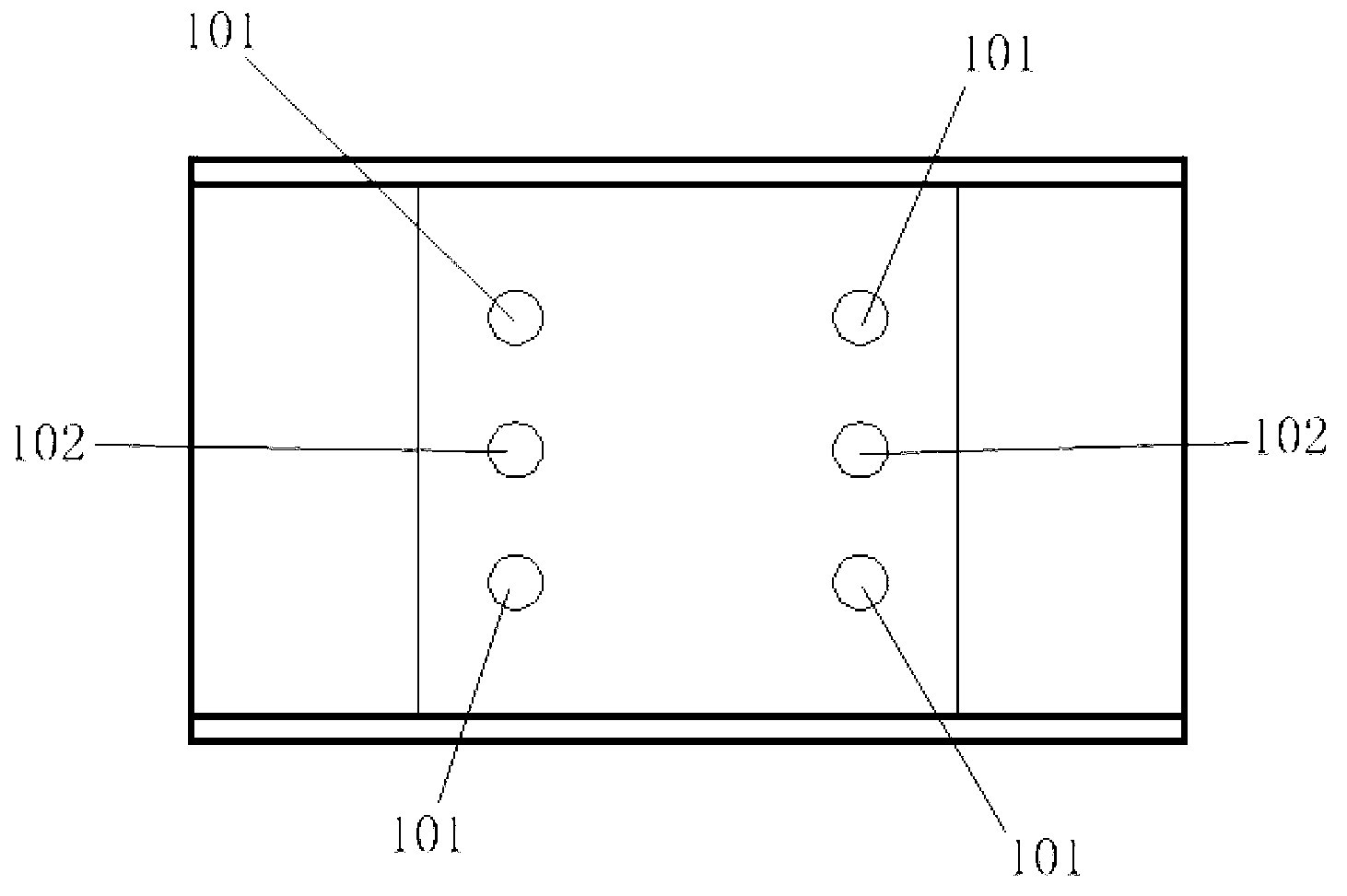

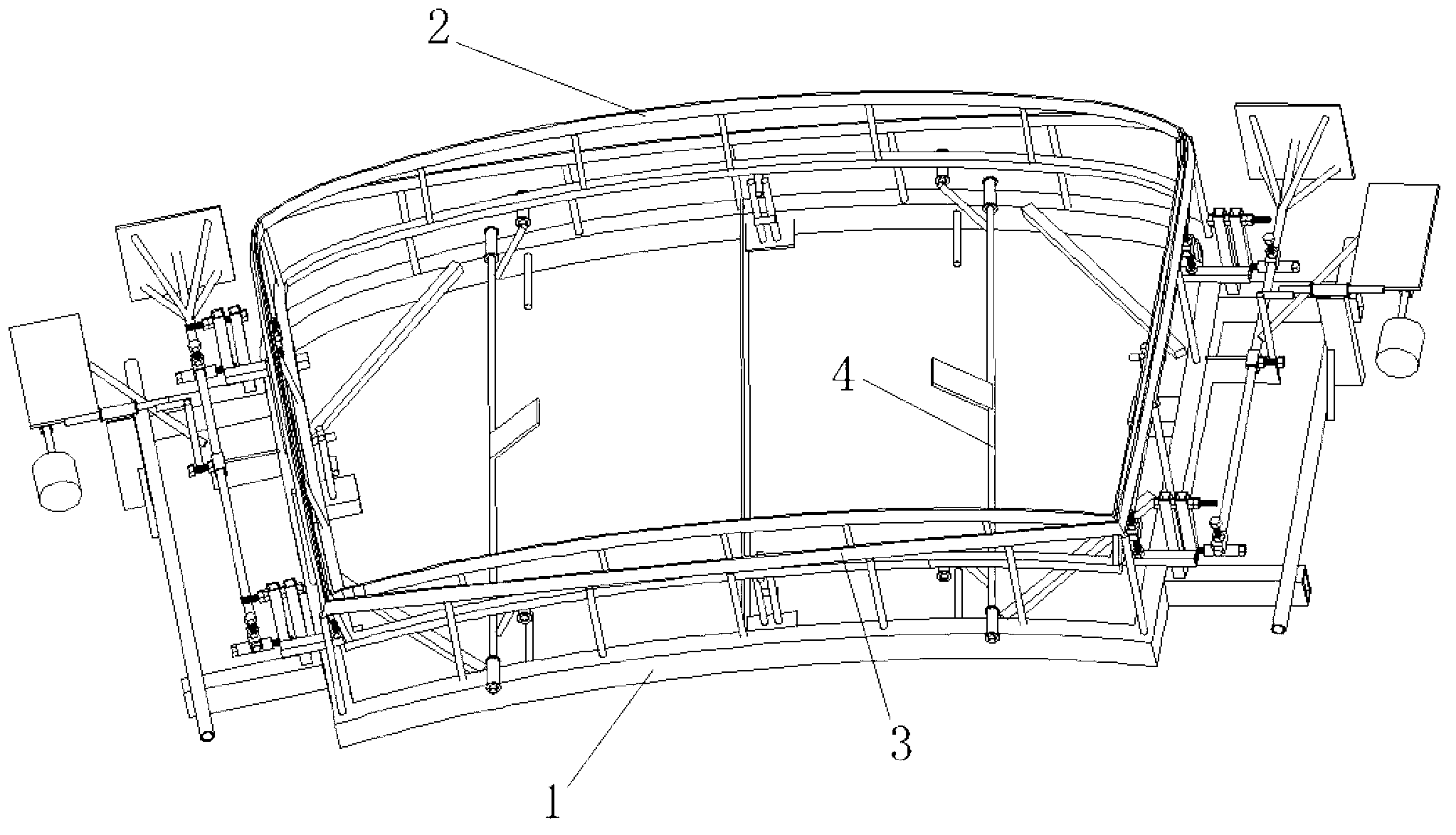

[0032] Such as figure 2 Shown in the first embodiment of the present invention, the automotive glass secondary molding baking mold shown in it includes a base 1, a first molding frame 2, a second molding frame 3 and a reset mechanism 4, and the first molding frame described in the figure The forming frame 2 is preferably located inside the second forming frame 3, which is convenient for setting the reset mechanism 4, but it is not limited to this situation, and the first forming frame 2 can be arranged outside the second forming frame 3 according to requirements . There are also some unmarked components and mechanisms in the figure, because these components and mechanisms do not affect the description of the invention points of the present invention, so they will not be introduced one by one in the present invention.

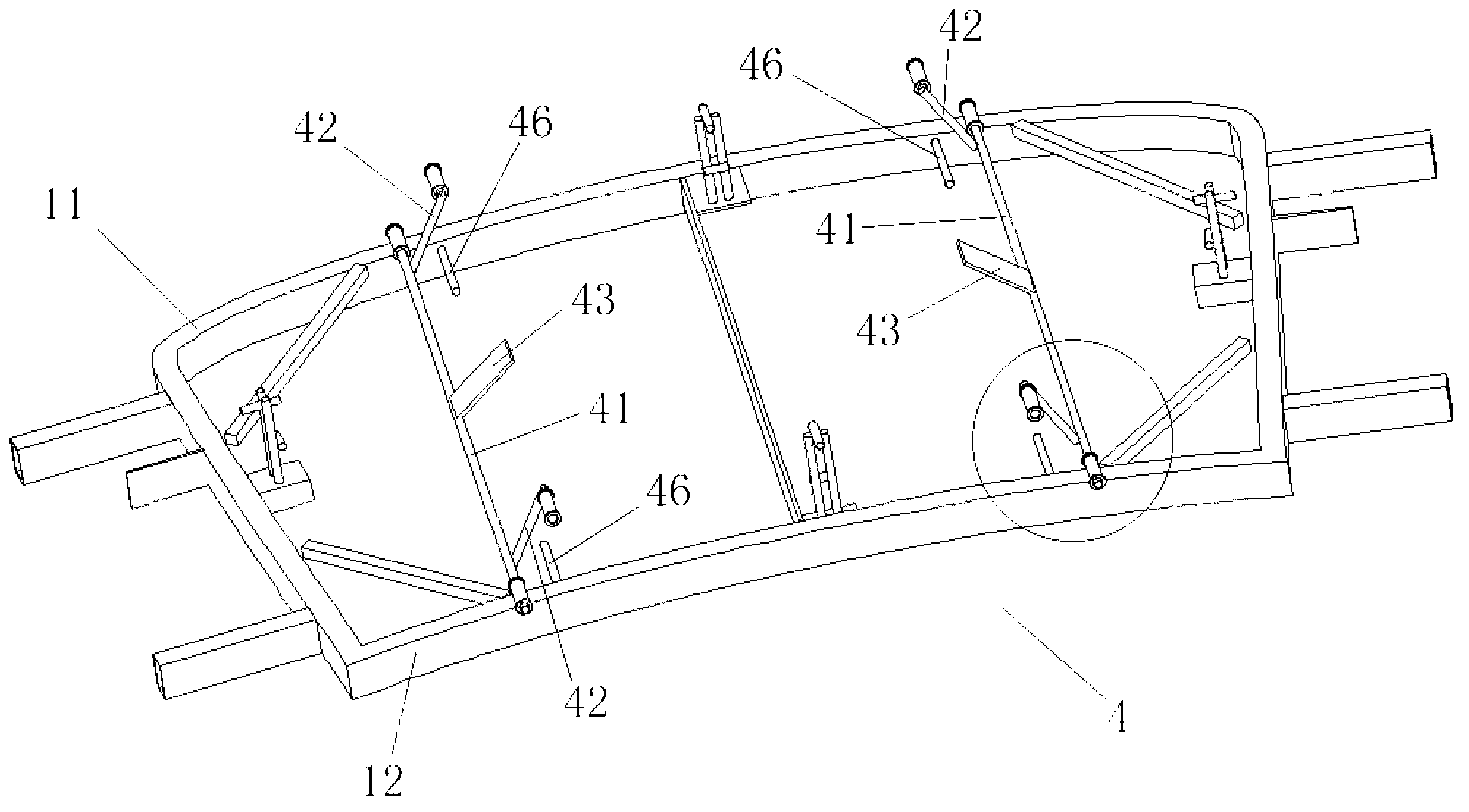

[0033] Such as image 3 As shown, the reset mechanism 4 includes two rotating rods 41 parallel to each other, four first forming frame support arms 42 and tw...

no. 2 example

[0048] Such as Figure 5 As shown in the second embodiment of the present invention, the automotive glass secondary molding baking mold shown in it includes a base 1, a first molding frame 2, a second molding frame 3, an anti-weight mechanism 5 and a reset mechanism 4. This kind of auto glass secondary molding baking mold with anti-weight mechanism is generally used in the baking and bending process of glass plates with complex curvature and large curvature. The first forming frame 2 in the figure is located inside the second forming frame 3 . There are also some unmarked components and mechanisms in the figure, because these components and mechanisms do not affect the description of the invention points of the present invention, so they will not be introduced one by one in the present invention.

[0049] Such as Figure 6 As shown, the second forming frame 3 includes a movable outer frame 31 and a fixed outer frame 32, wherein the fixed outer frame 32 is fixed on the base 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com