Cigar coating raw material pretreatment process based on machine vision

A machine vision and cigar technology, applied in the field of tobacco technology, can solve the problems of difficult to realize high-value utilization of tobacco leaf resources, many manual pretreatment processes, and low utilization rate of raw materials, so as to save the cost of tobacco leaf raw materials and improve the quality of classification and cutting , The effect of simplifying the pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

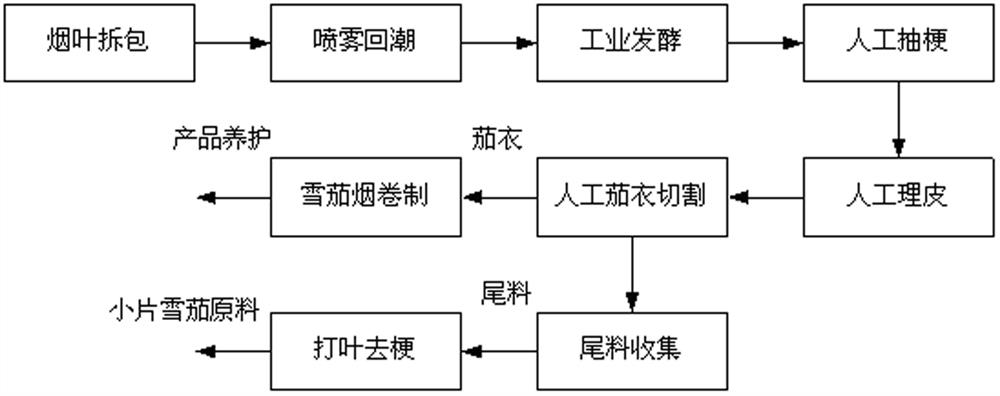

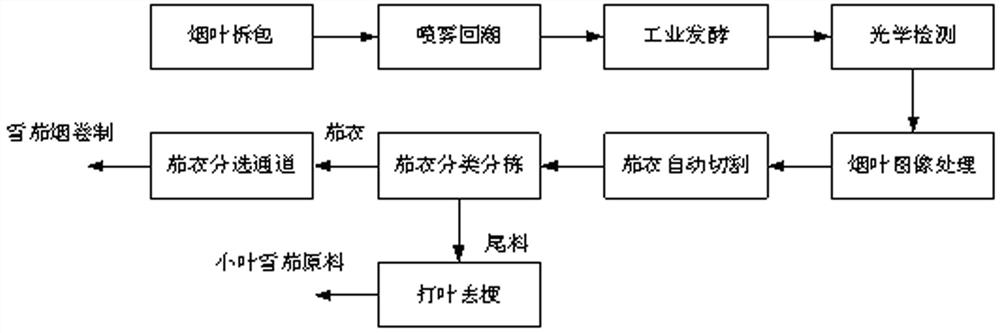

[0025] The present invention is combined as follows figure 2 The working principle and process will be further explained:

[0026] attached figure 2 This is the cigar wrapper raw material pretreatment process of the present invention. The cigar wrapper raw material is subjected to moisture rejuvenation and industrial fermentation treatment. Collect the tobacco leaf images on the belt in real time; the image processing unit analyzes the outline and size of the tobacco leaves and the position of the veins in the middle of the tobacco leaves in real time. According to the principle of the highest utilization efficiency of cutting the wrapper from the tobacco raw material, the image processing unit optimizes and determines the cutting quantity and cutting path of the wrapper on the tobacco leaf; at the same time, for each target cutting area, extract and analyze its color information and Defect information, classify and identify the quality of the wrapper; the servo motor of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com