Manufacturing method of liquid crystal display device and liquid crystal display panel and manufacturing equipment of liquid crystal display device and liquid crystal display panel

A technology for a liquid crystal display panel and a manufacturing method, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of broken bright spots, affect the display effect, and difficulty of liquid crystal molecules, so as to reduce the broken bright spots, improve the display effect, and reduce dark lines. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The manufacturing method of the liquid crystal display panel of the present invention can reduce the appearance of dark lines and broken bright spots of the liquid crystal display panel, and improve the display effect of the liquid crystal display panel.

[0028] The present invention will be described in detail below with reference to the drawings and embodiments.

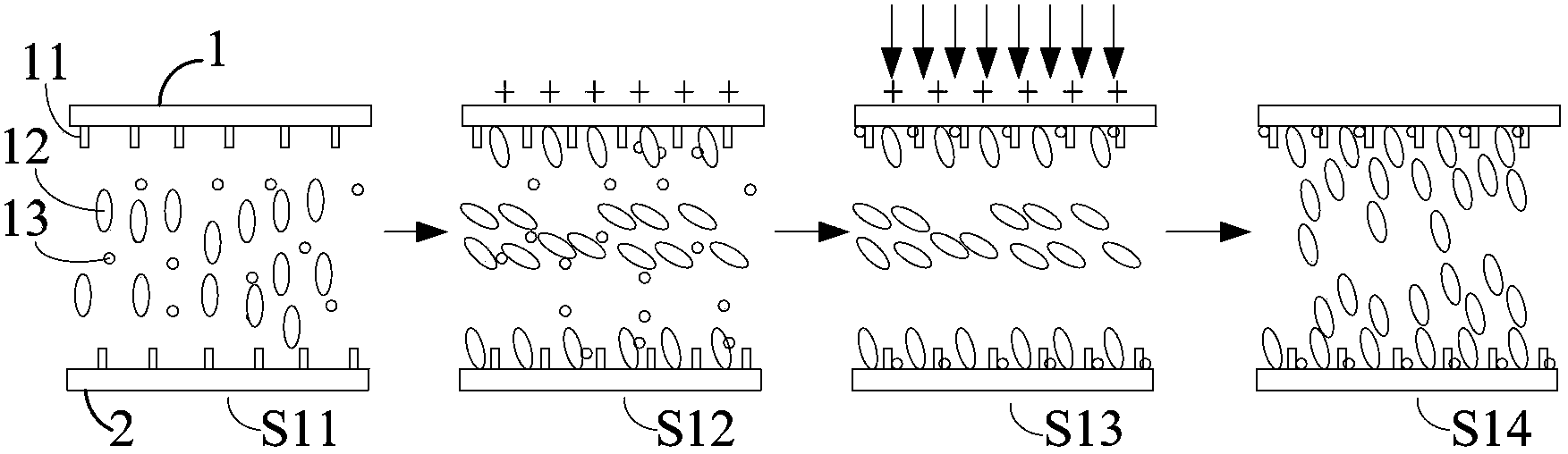

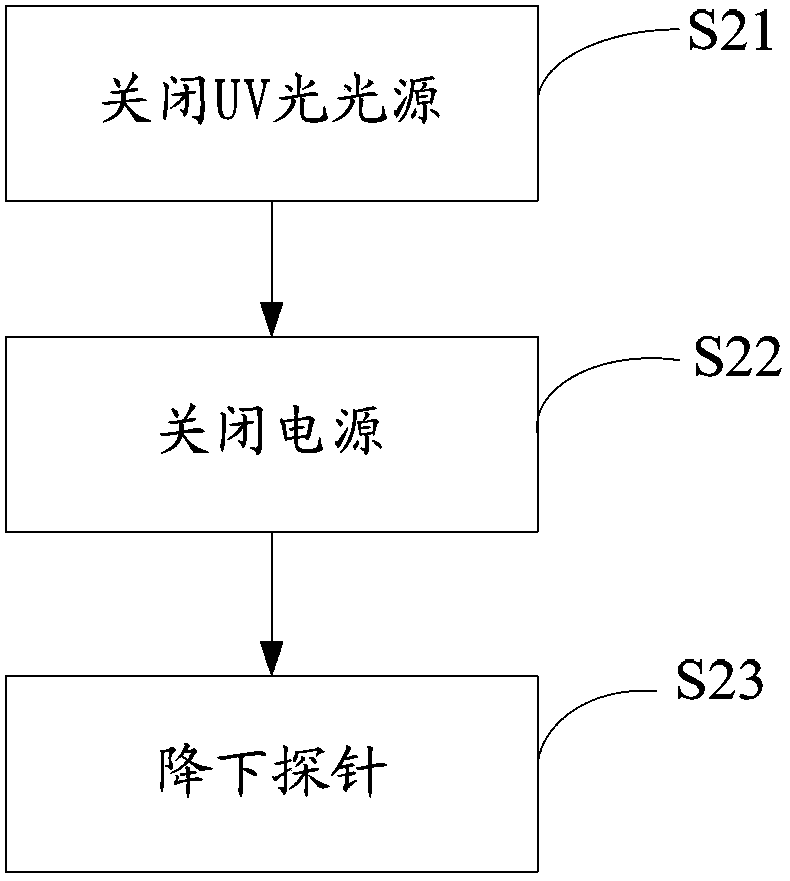

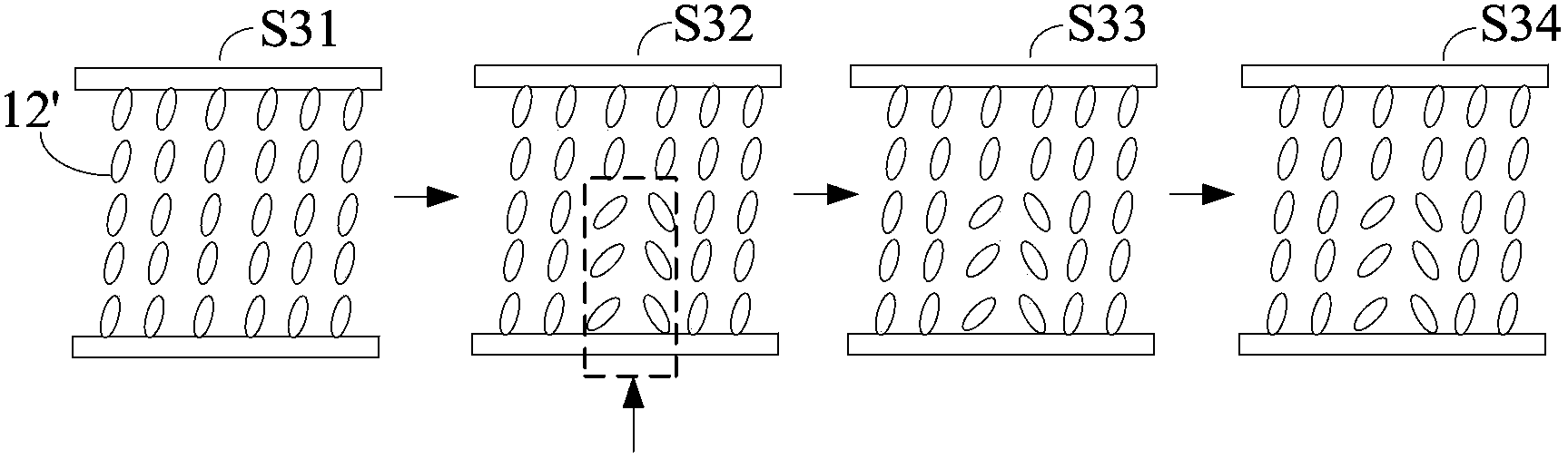

[0029] refer to Figure 4 , an embodiment of the manufacturing method of the liquid crystal display panel of the present invention comprises steps:

[0030] Step S101: Applying a voltage between the upper and lower substrates of the liquid crystal display panel to form an electric field.

[0031] For the first UV light irradiation process in the PSVA liquid crystal display panel production process, by means of the electrode structure in the upper and lower substrates on both sides of the liquid crystal molecular layer, the electrode structure is turned on and a voltage is applied to it, so that the upper a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap