Model pile in shear structure for model testing

A technology of shear structure and model test, applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problems of comprehensive evaluation of reinforcement effect and inability to comprehensively reflect piles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

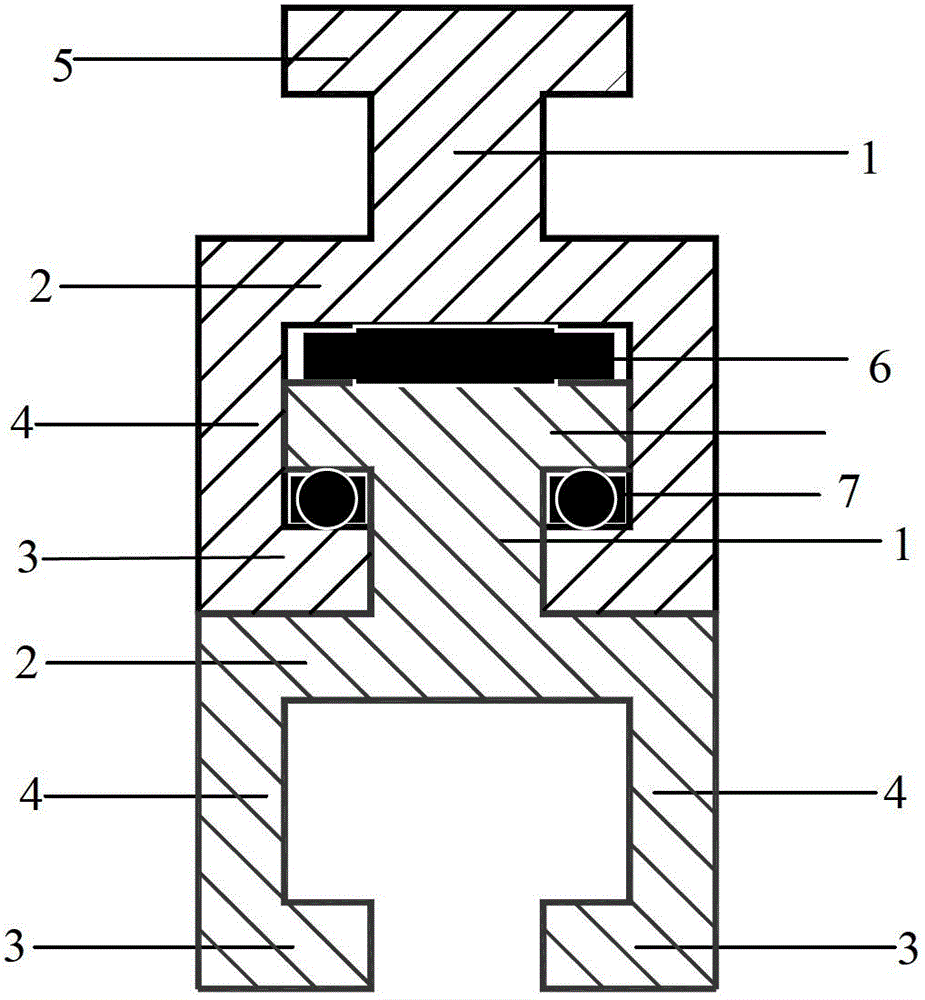

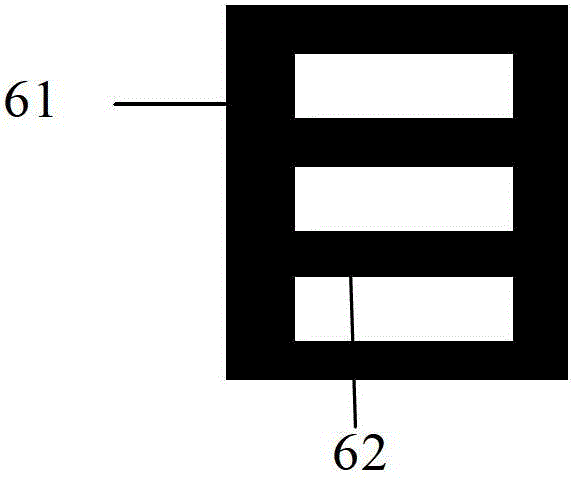

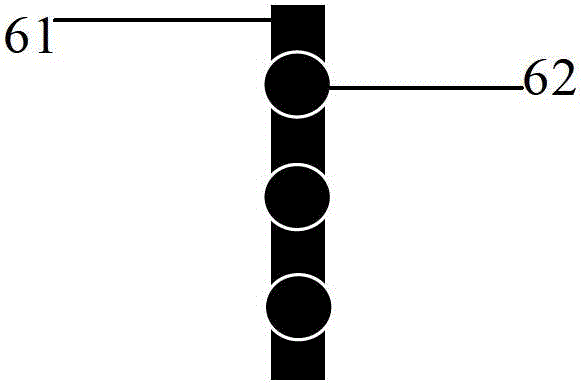

[0015] like figure 1 As shown, the present invention is a shear structure model pile used for model tests, which is composed of a plurality of shear structure modules 1 sequentially occluded, each shear structure module 1 is made of aluminum, and the assembly size is determined according to needs. The cross-section of the shear structure module 1 is mainly in the shape of an I-shape. Block 3, the length of the upper horizontal side 5 in the I-shaped shape is consistent with the distance between the two vertical sides 4, and the upper horizontal side 5 of the shear structure module 1 is inserted between the two vertical sides 4 of the adjacent module to achieve engagement. After the occlusion is realized, a cylindrical roller 6 perpendicular to the length direction of the upper transverse edge 5 is arranged between the upper transverse edge 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com