Method and apparatus for dispensing flowable material into a mold

A technology of distributing device and mold, applied in the direction of household appliances, other household appliances, applications, etc., can solve the problems of defective glasses and affecting the accuracy rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

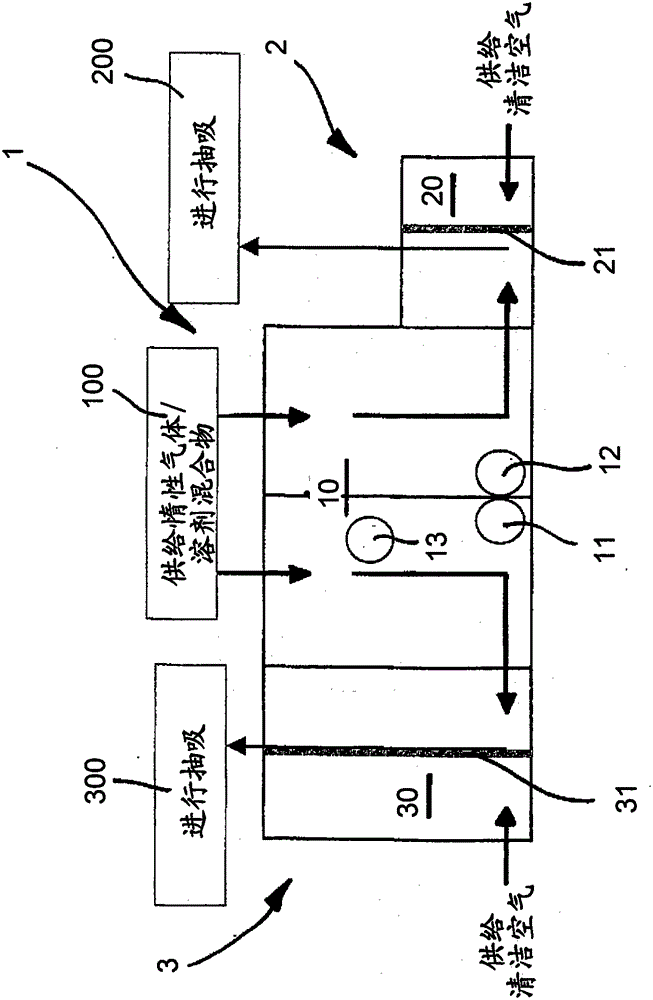

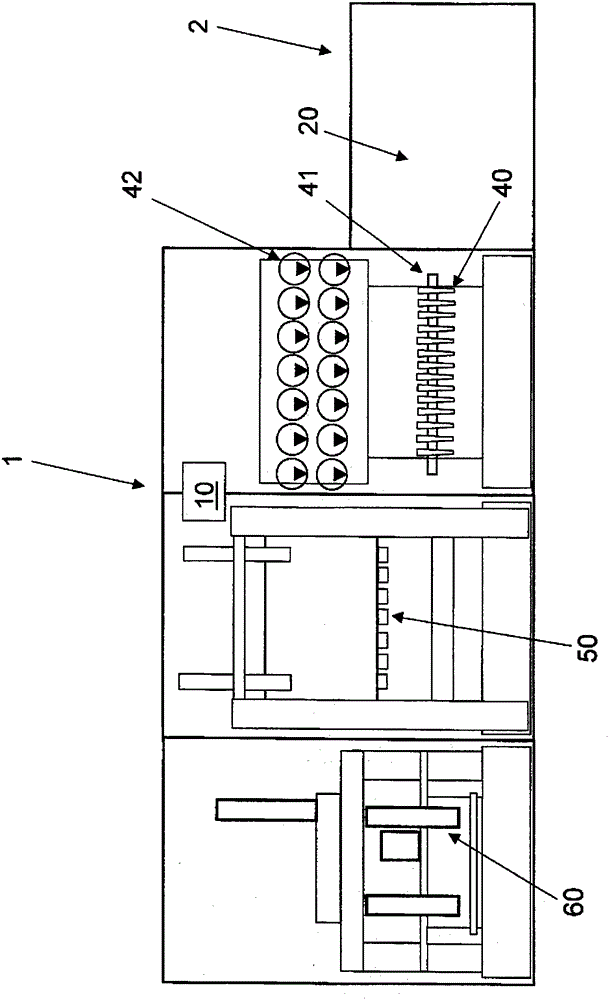

[0030] Attached below figure 1 explain the invention, figure 1 It is a schematic diagram of the structure of the outer cover 1, the entrance door 2 and the exit door 3. The inlet door 2 and the outlet door 3 form boundaries 21 and 31 in the form of "walls" generated by various fluids. Such as figure 1 As shown, during operation a mixture of an inert gas (eg nitrogen) and a solvent (eg propanol) is continuously delivered through the upper wall of the enclosure 1 into the interior 10 of the enclosure 1 with the aid of suitable supply means 100 . further as figure 1As shown, the interior 20 of the inlet valve 2 is sucked through the upper wall of the inlet valve 2 under the action of a suitable suction device 200 , such as a suction pump. As a result, clean air (filtered, eg through a filter) and a gas / solvent mixture are introduced into the interior 20 of the inlet valve 2 by suctioning the interior 20 of the inlet valve 2 . Two fluids (inert gas / solvent mixture and clean a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com