Water-proof structure of tunnel lining joint in shield-method construction

A technology of waterproof structure and shield method, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., and can solve the problems of large number of joints and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

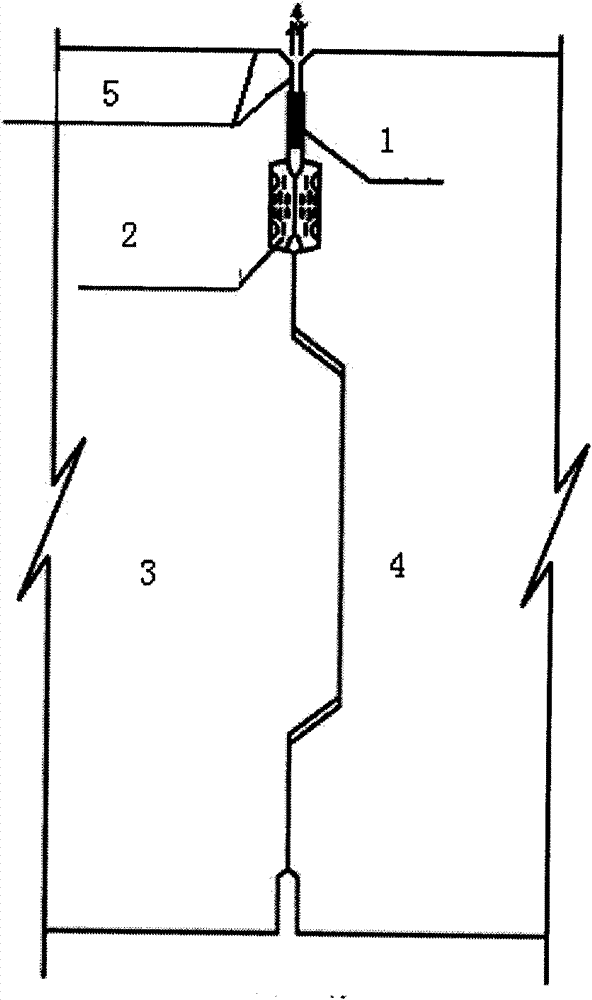

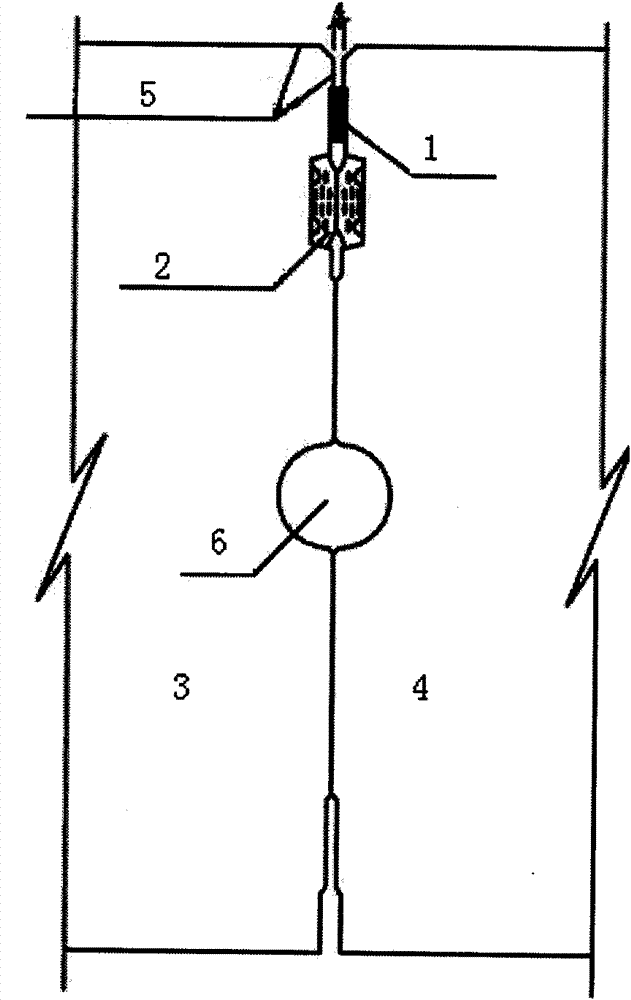

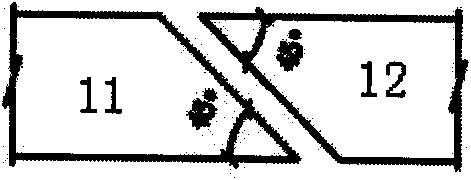

[0019] Such as Figure 1~3 As shown, a shield tunnel lining joint waterproof structure includes a water retaining strip 1 and an elastic rubber gasket 2, and the water retaining strip 1 and the elastic rubber gasket 2 are arranged up and down between the tunnel lining segments. At seams, the seams between tunnel lining segments include ring seams and longitudinal seams. The left segment 3 of the tunnel lining segment and the middle of the right segment 4 are convex-concave butt joints, that is, the middle of the left segment 3 is provided with a convex platform protruding to the right, and the middle of the right segment 4 is provided with the convex platform. There is a groove matching the platform, and a positioning rod 6 is provided in the middle of the longitudinal joint surface of the left segment 3 and the right segment 4, and the waterproof performance is enhanced through the structural design of the tunnel lining segment itself.

[0020] The water retaining strip 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com