Waterproof structure for pipe-jacking method tunnel union joint

A technology of waterproof structure and tunnel pipe, which is applied in the direction of non-detachable pipe connection, pipe/pipe joint/fitting, pipe laying and maintenance, etc. It can solve the problems of self-heavy pipe joints, tunnel water leakage, uneven upper and lower gaps at pipe joint joints, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

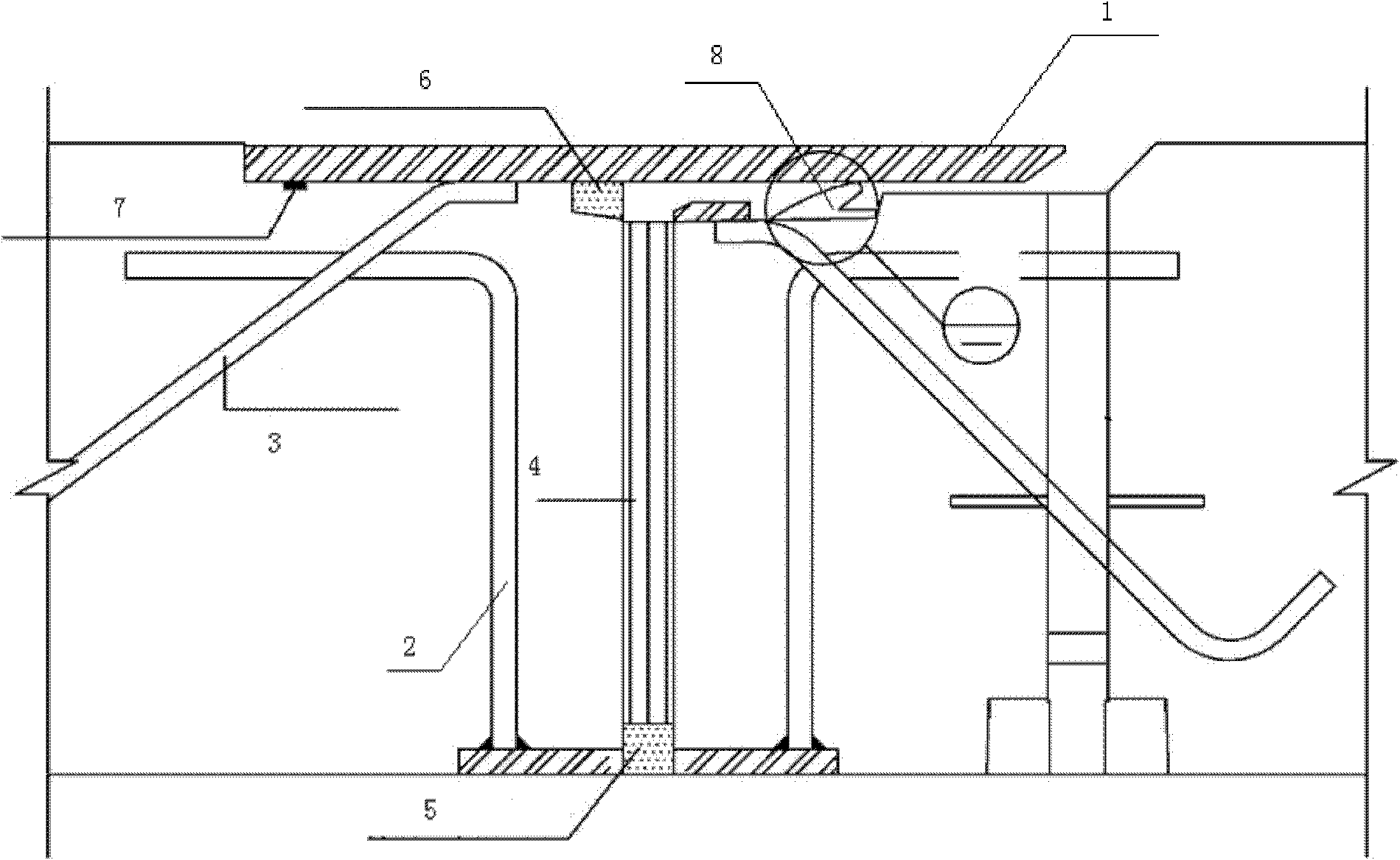

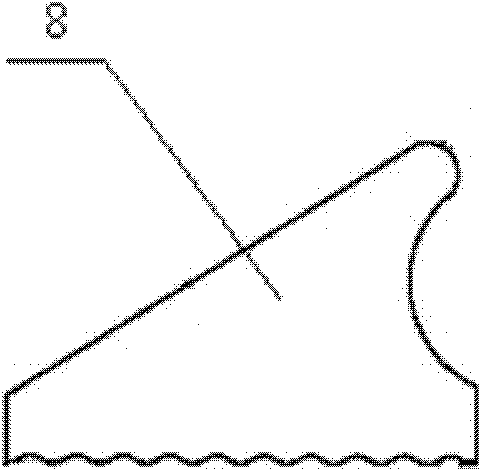

[0017] Such as Figure 1~2 As shown in the figure, a waterproof structure for the connection of pipe jacking tunnel pipe joints, including the left and right pipes abutted together, the joint is in the shape of steps, the steps are provided with a cover plate 1, and two anchors are arranged in the left and right pipes. One of them is set at the bottom of the jacking pipe, which is an inverted L-shaped anchor bar 2, and the other is set at the top of the jacking tube, which is a hook-shaped anchor bar 3 intersecting with the L-shaped anchor bar 2. The left jacking tube and the right jacking tube There is a plywood 4 between them, the bottom of the plywood 4 is filled with a high modulus polyurethane sealant 5, the top of the left jacking pipe is filled with a low modulus polyurethane sealant 6 near the seam, and the connecting end of the cover plate 1 and the left jacking pipe is provided with a single Component water-expandable polyurethane sealant 7, the right top pipe is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com