Method for fabricating flexible substrate LCD (liquid crystal display) and flexible substrate LCD

A technology of flexible substrates and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven distribution, uneven thickness of LCD boxes, etc., and achieve the effect of solving uneven thickness of boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

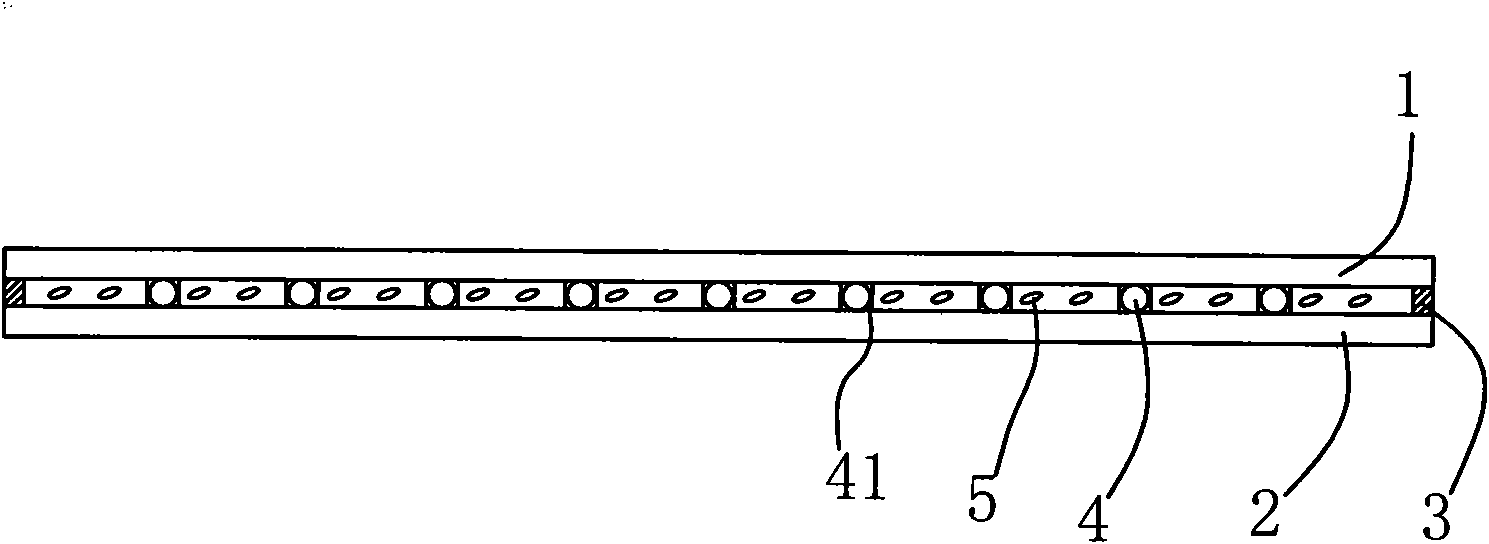

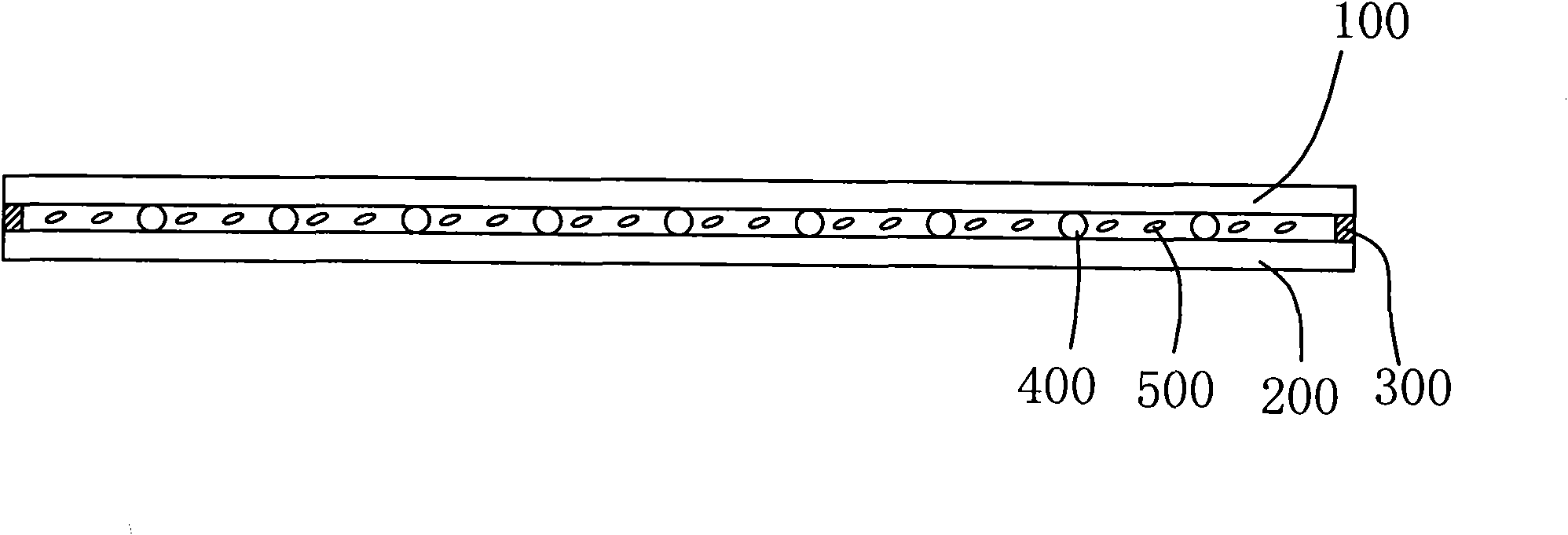

[0023] The invention provides a method for manufacturing a flexible substrate LCD, comprising a flexible upper substrate and a flexible lower substrate with transparent electrodes, including the following steps,

[0024] (1), alignment film manufacturing step, make alignment film on the transparent electrode of flexible upper substrate and flexible lower substrate respectively; The making of alignment film can adopt conventional method, promptly on the transparent electrode of flexible upper substrate and flexible lower substrate Coat the orientation film separately, and after curing, use a rubbing cloth for orientation treatment;

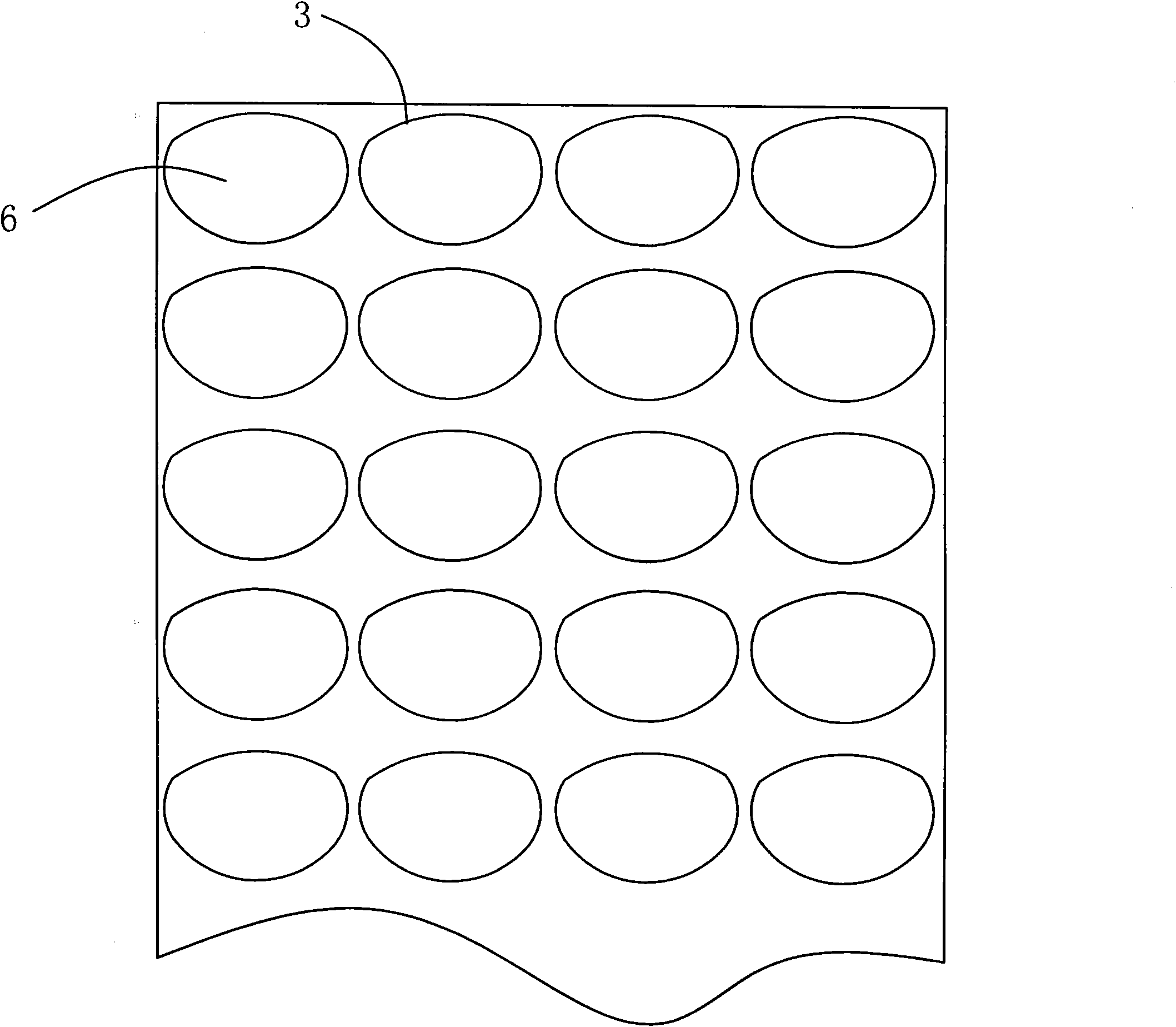

[0025] (2), the step of printing spacers, printing rubber particles on the flexible upper substrate or the flexible lower substrate, and at least one spherical spacer is contained in each of the rubber particles; the specific method of printing the spacers is, first Many hemispherical pits are evenly arranged on the printing roller, and spherical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com