Method for dispersing spherical spacers, liquid crystal panel and display device

A liquid crystal panel and spacer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of uneven cell thickness, and achieve the effect of solving uneven cell thickness and inhibiting movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The basic idea of the present invention is to fix the spherical spacer by utilizing the property of the adhesive of the polyimide solution and changing the spraying and curing process of the spherical spacer, effectively inhibiting the movement of the spherical spacer , which solves the uneven thickness of the cell caused by the impact of the liquid crystal on the spherical spacer.

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

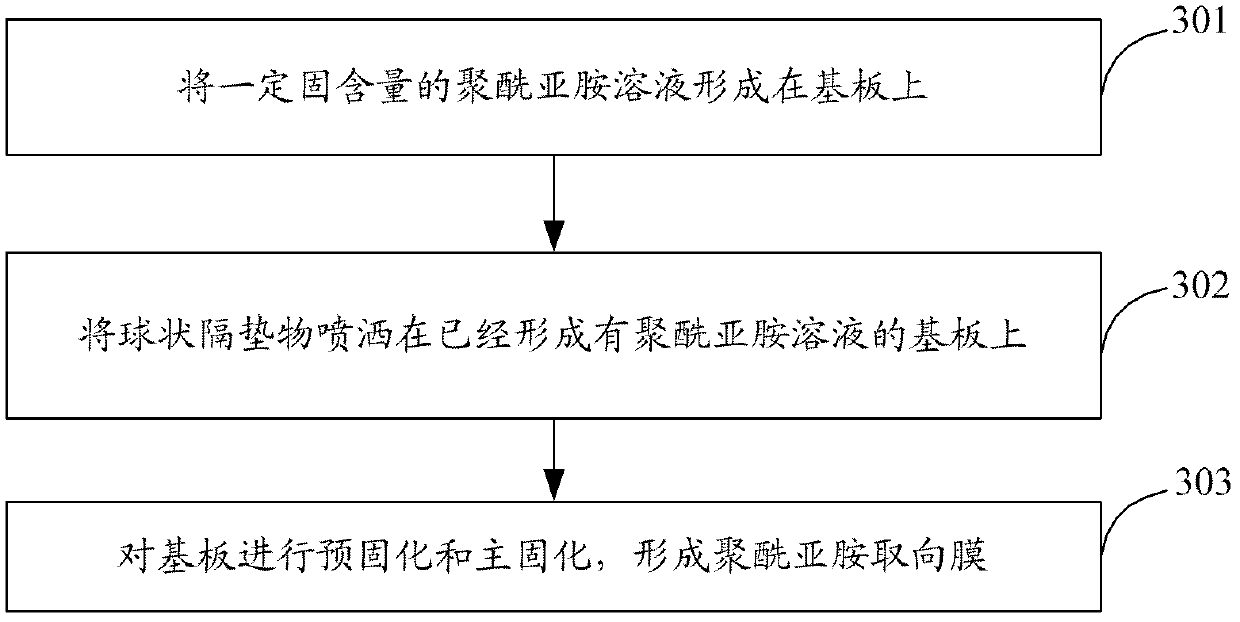

[0032] image 3 The flow chart of the method for dispersing the spherical spacer of the embodiment of the present invention is shown, as image 3 As shown, in this embodiment, the method includes the following steps:

[0033] 301: forming a polyimide solution with a certain solid content on the substrate;

[0034] Wherein, the solid content of the polyimide solution transferred on the substrate is 3%, because the concentration of such polyimide solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com