Rotary compressor and rotary machine

A rotary compressor and compression mechanism technology, applied in the field of rotating machinery, can solve the problems of lack of lubricating oil, unbalanced lubricating oil, long pipeline length, etc., and achieve the effects of short response time, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage.

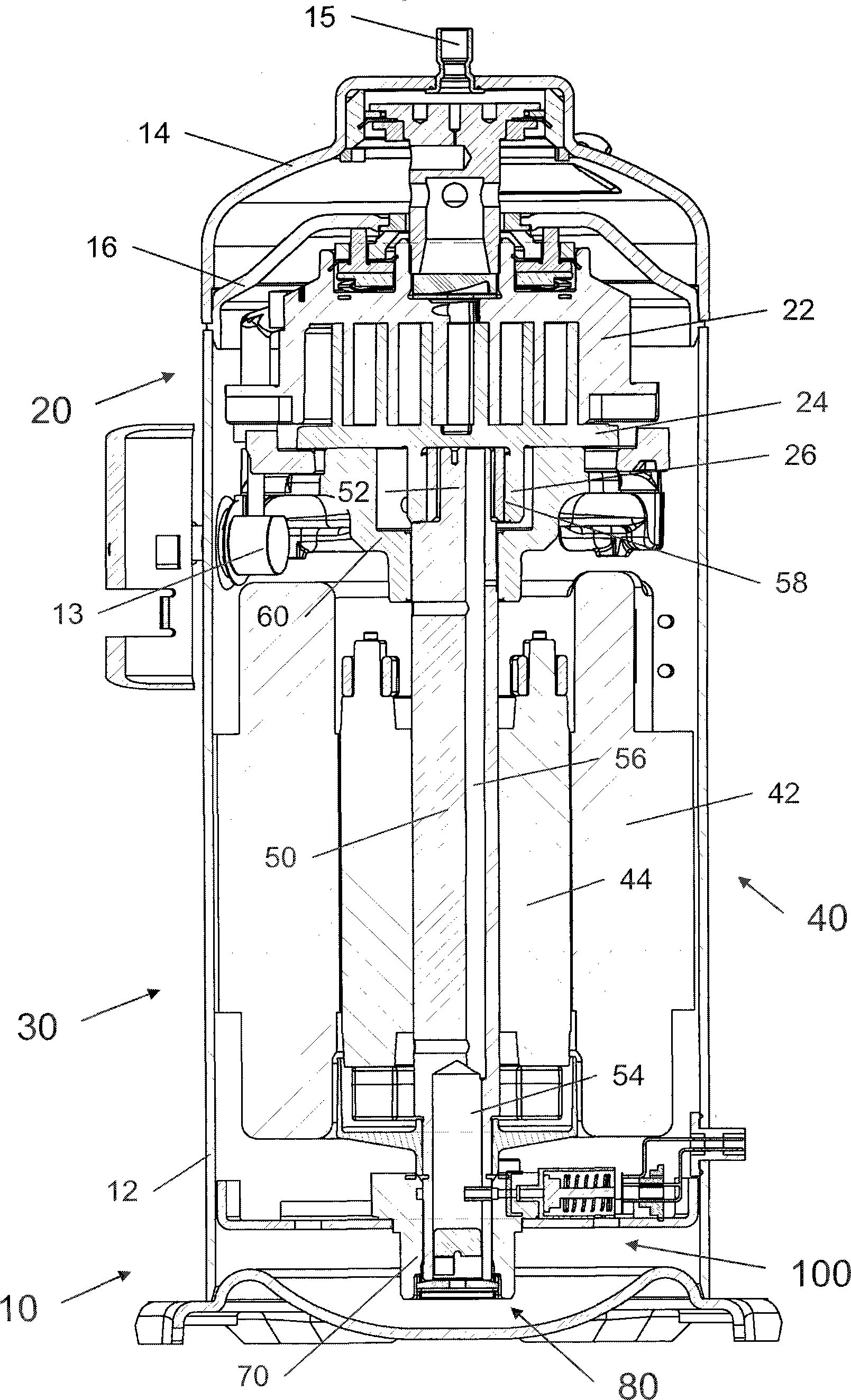

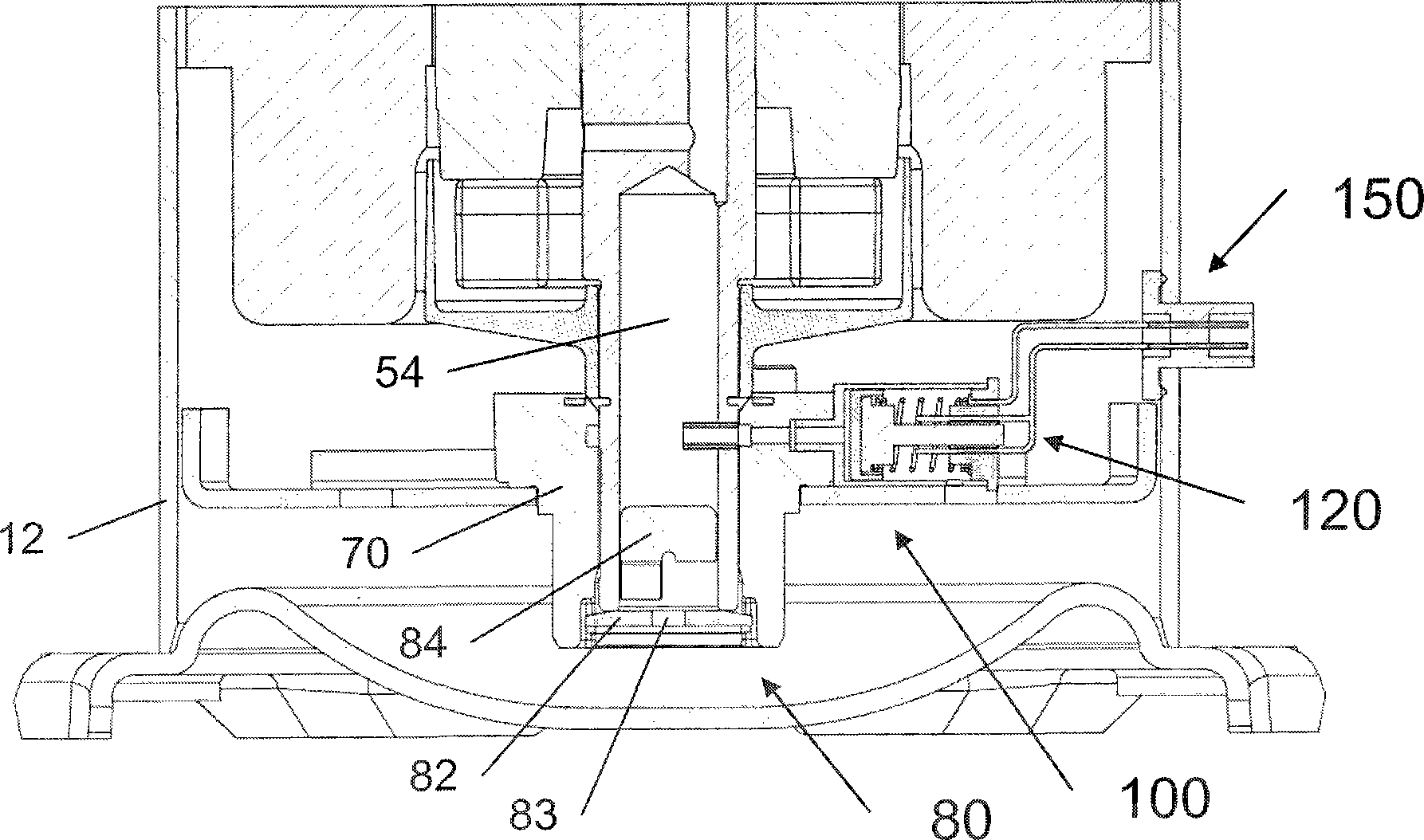

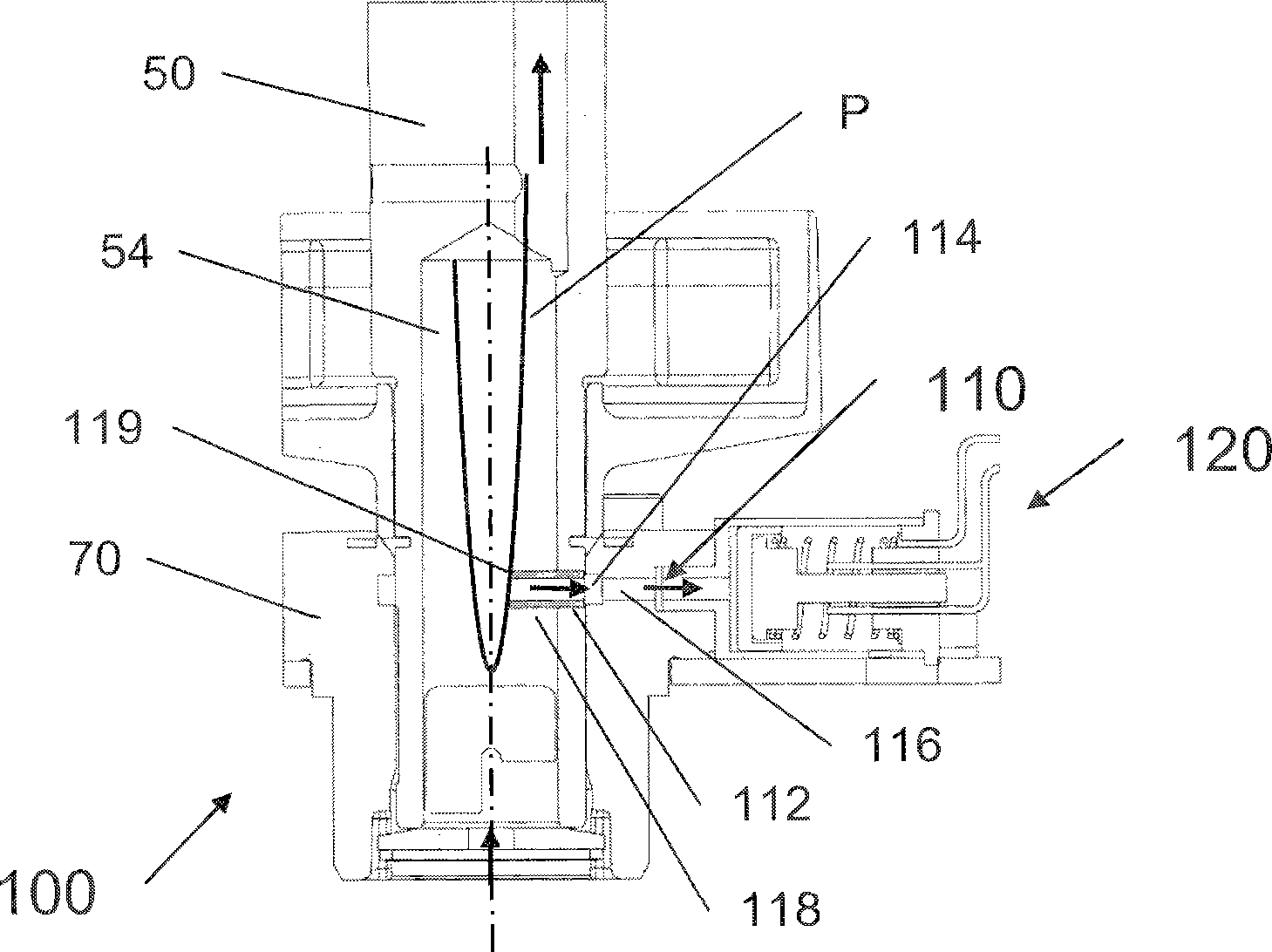

[0071] The following will refer to figure 1 The basic configuration of the rotary compressor according to the present invention is described. figure 1 is a schematic sectional view of a rotary compressor according to an embodiment of the present invention. figure 1 The rotary compressor shown is a scroll compressor, however, those skilled in the art should understand that the present invention is not limited to the scroll compressor shown in the figures, but the present invention can also be applied to other types including rotary compressors. Shaft compressors, such as screw compressors, rotary compressors, etc., and any type of rotating machinery that includes a rotating shaft. In addition, the present invention is applicable not only to vertical compressors whose rotary shafts are vertically oriented, but also to horizontal comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com