Construction method of flow field numerical model in minimum quantity lubrication cutting area

A technology of minimum quantity lubrication and numerical model, which is applied in the field of mechanical cutting, can solve the problems affecting the simulation results, and the public report of the numerical model of the flow field in the cutting zone of the minimum quantity lubrication has not been found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

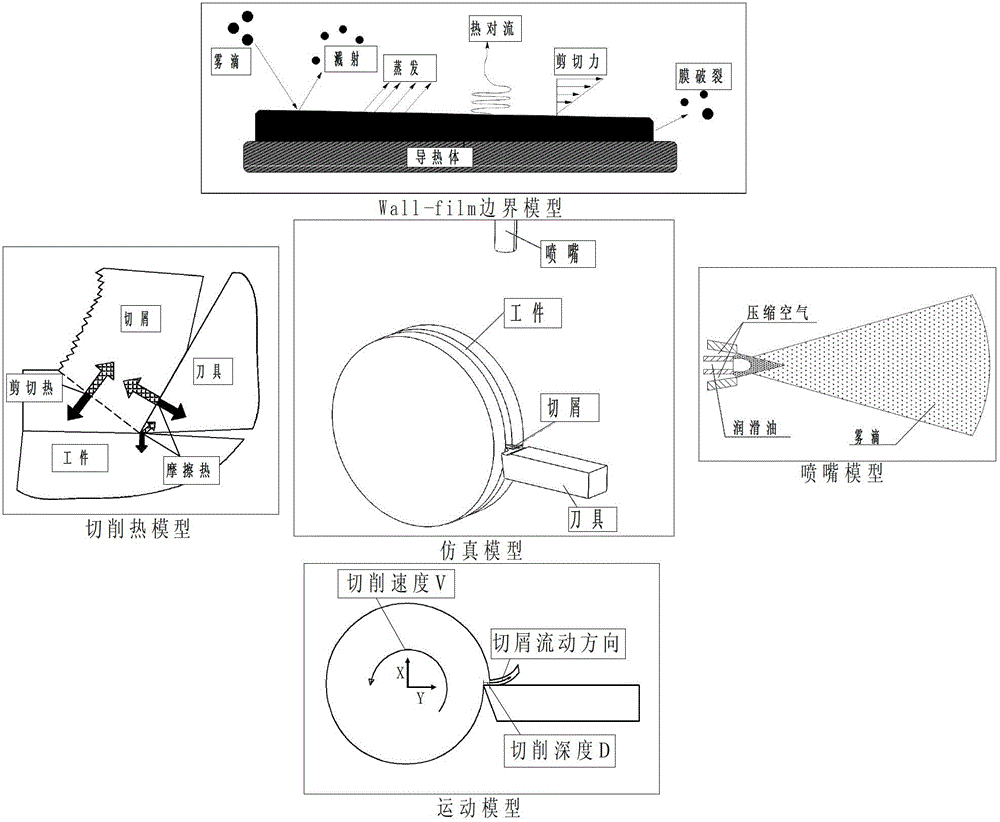

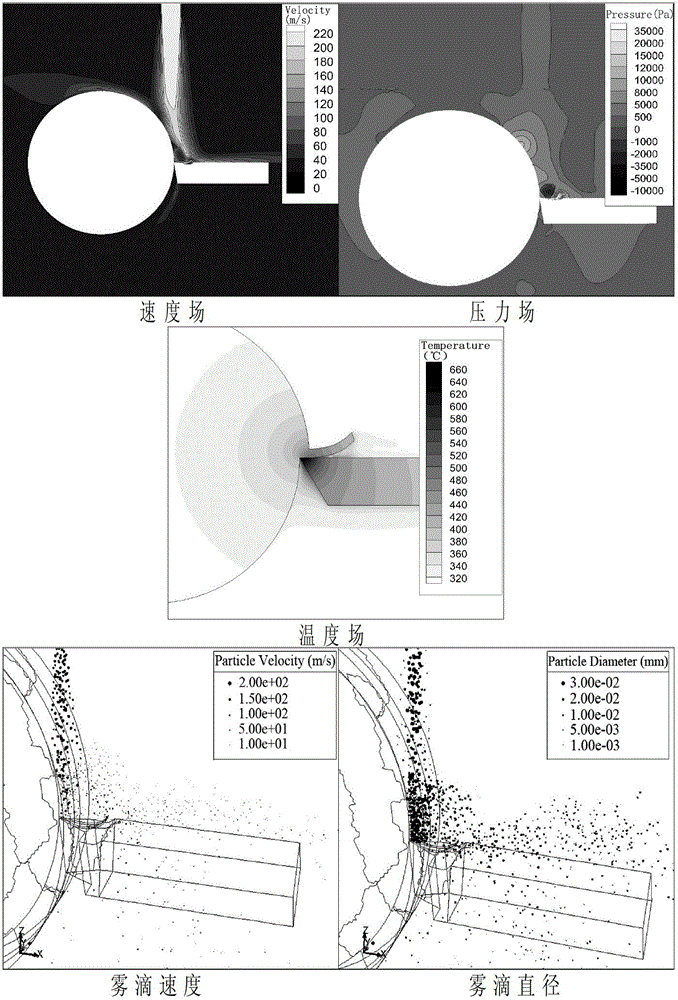

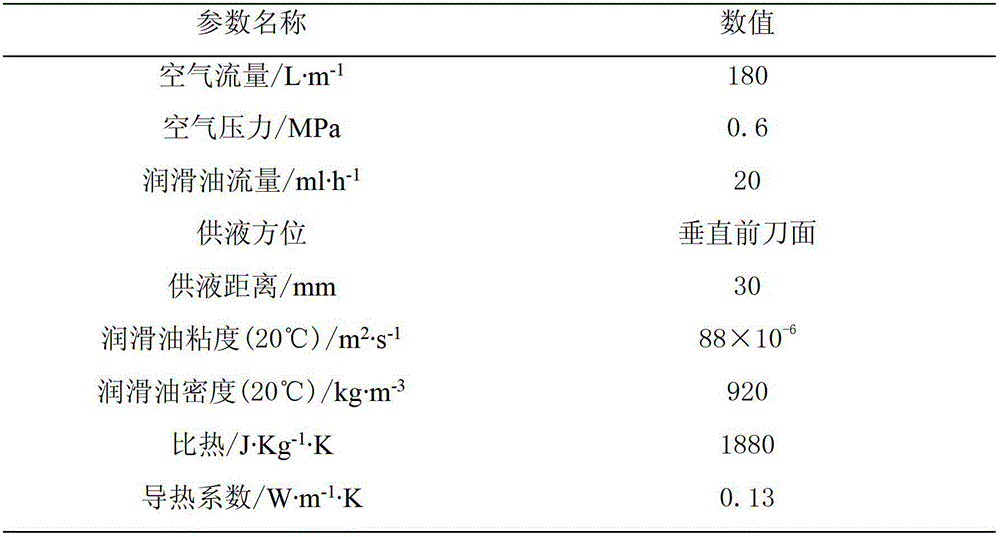

[0022] The method for constructing the numerical model of the flow field in the MQL cutting zone of the present invention combines four factors that will affect the MQL in the cutting zone during the cutting process: the relative motion between the workpiece and the tool, the cutting heat generation during the cutting process, the boundary model and The DPM model suitable for minimum quantity lubrication is added to the simulation model to simulate the cutting process to the greatest extent, and by changing the input parameters of the simulation, the flow field distribution of the minimum quantity lubrication cutting area under different cutting parameters and lubrication parameters can be simulated. It includes the following steps:

[0023] The first step is to establish a two-dimensional or three-dimensional cutting model, which includes nozzles, workpieces, tools and chips.

[0024] The second step is to divide the established cutting two-dimensional or three-dimensional mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com