Hard microstrip circuit electroplating fixture

A microstrip circuit and electroplating fixture technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of easily damaged substrates, poor electrical contact at points, inconsistent tightening screws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

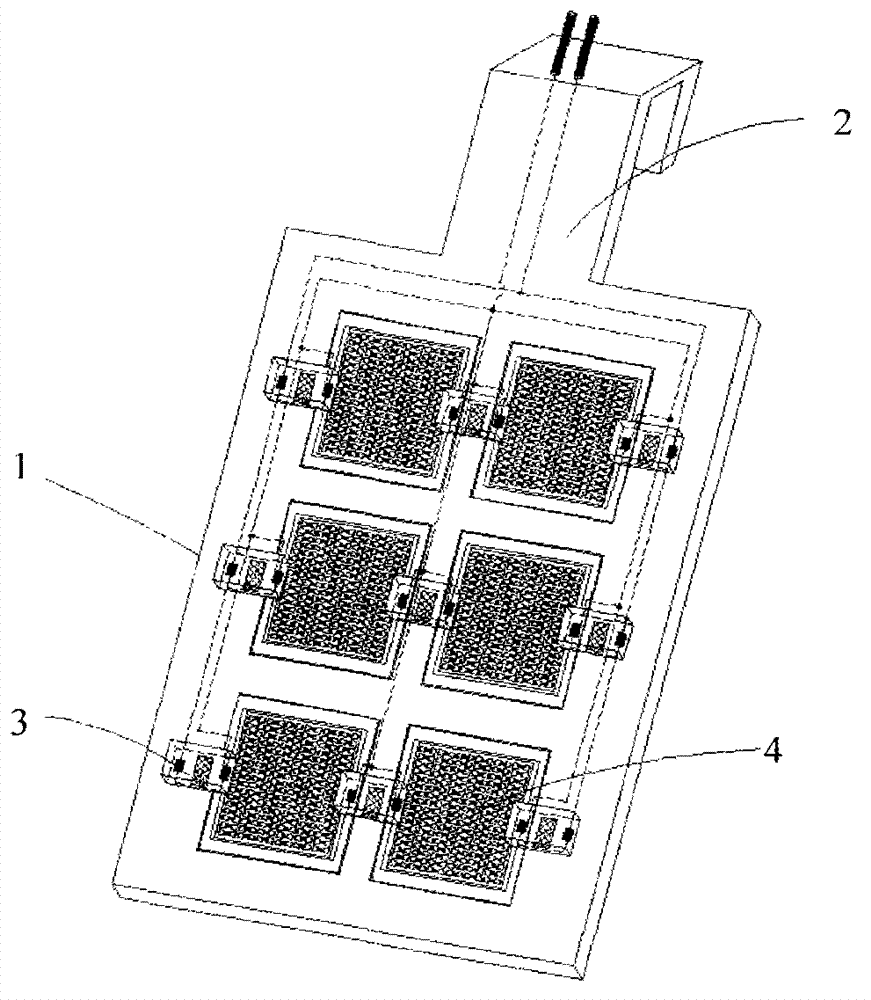

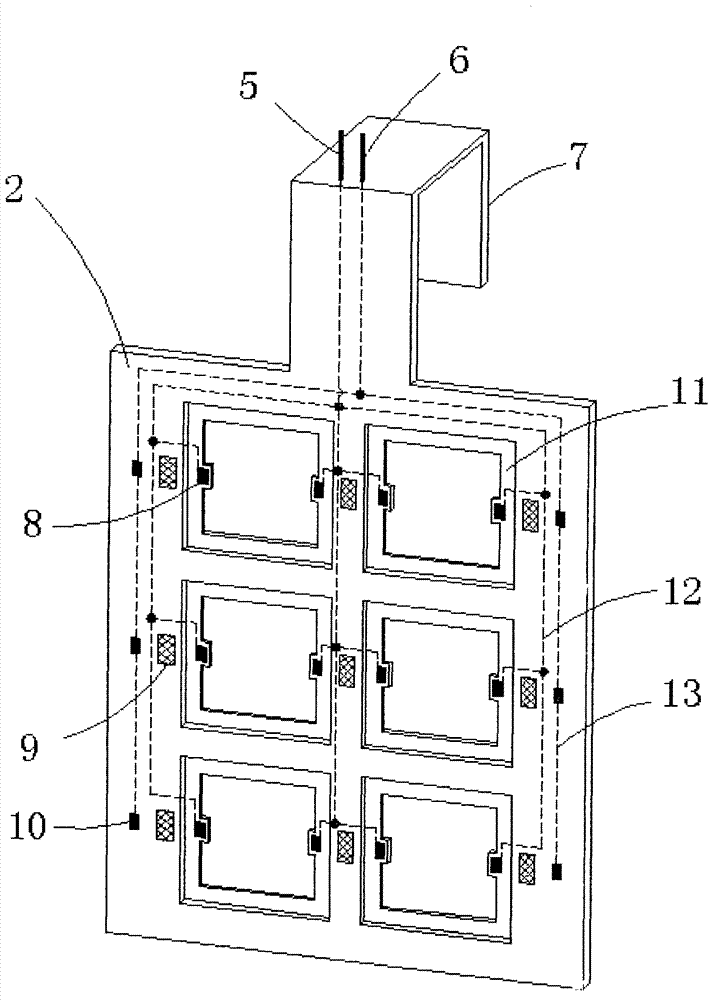

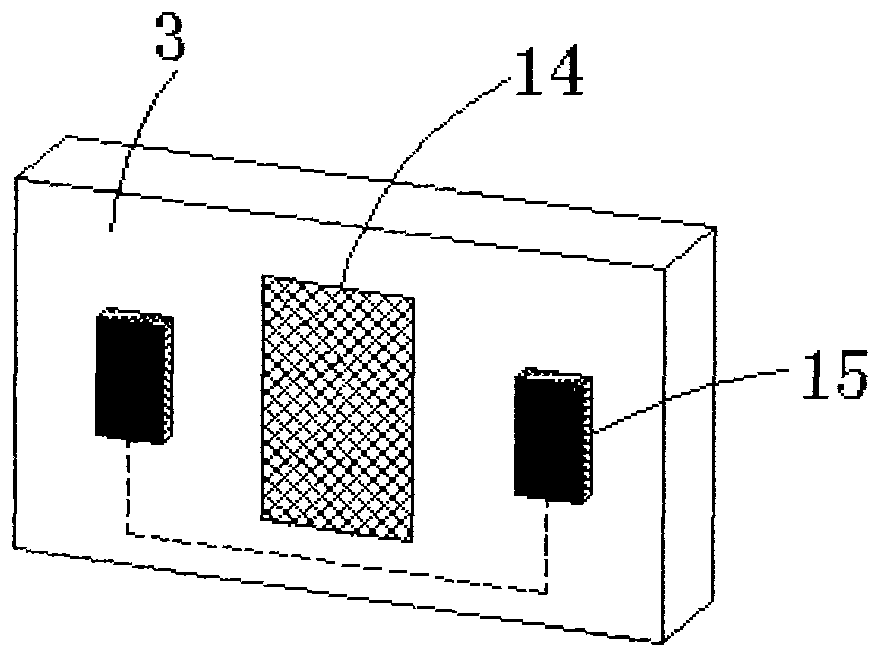

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0018] A rigid microstrip circuit electroplating fixture, including a main body and conductive electromagnetic force fingers, the main body includes a plurality of orderly arranged substrate frames, electrode I, electrode II and magnet I, and the conductive electromagnetic force finger includes electrode III and magnet II, the magnet I on the main body and the magnet II on the conductive electromagnetic force clamp finger attract each other so that the conductive magnetic force clamp finger fixes the hard microstrip circuit substrate in the substrate frame, the electrode I on the main body and the hard microstrip circuit The reverse side or the front side of the strip ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com