Hollow plate forming method and finished product

A molding method and hollow technology, which can be applied to hollow objects, sheets/boards, and other household appliances, etc., can solve the problems of non-environmental protection and failure of primary materials to be recycled and reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] For convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

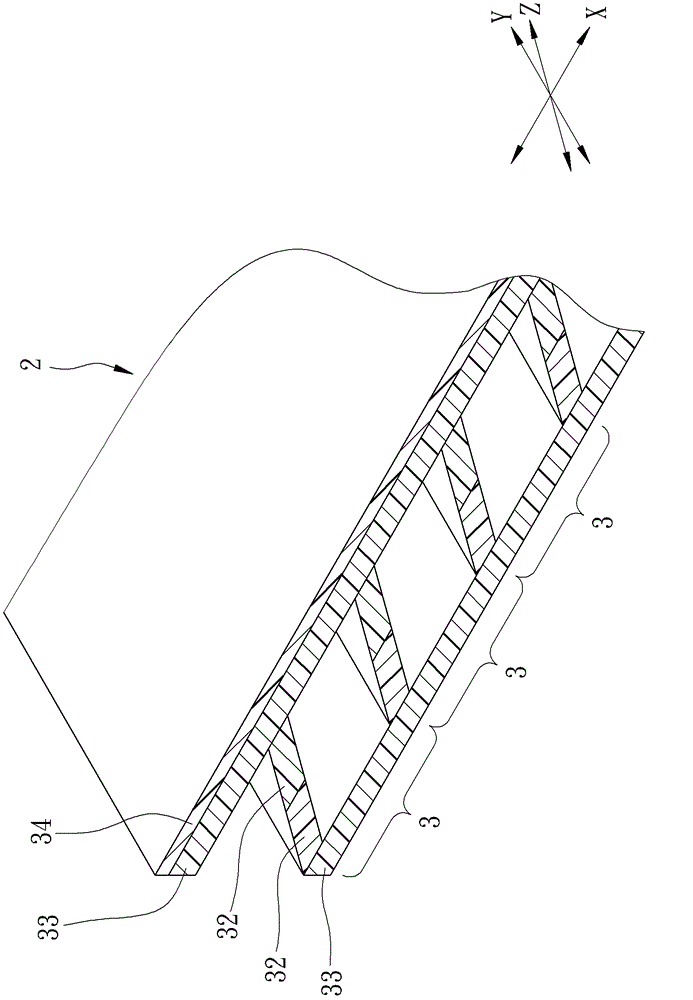

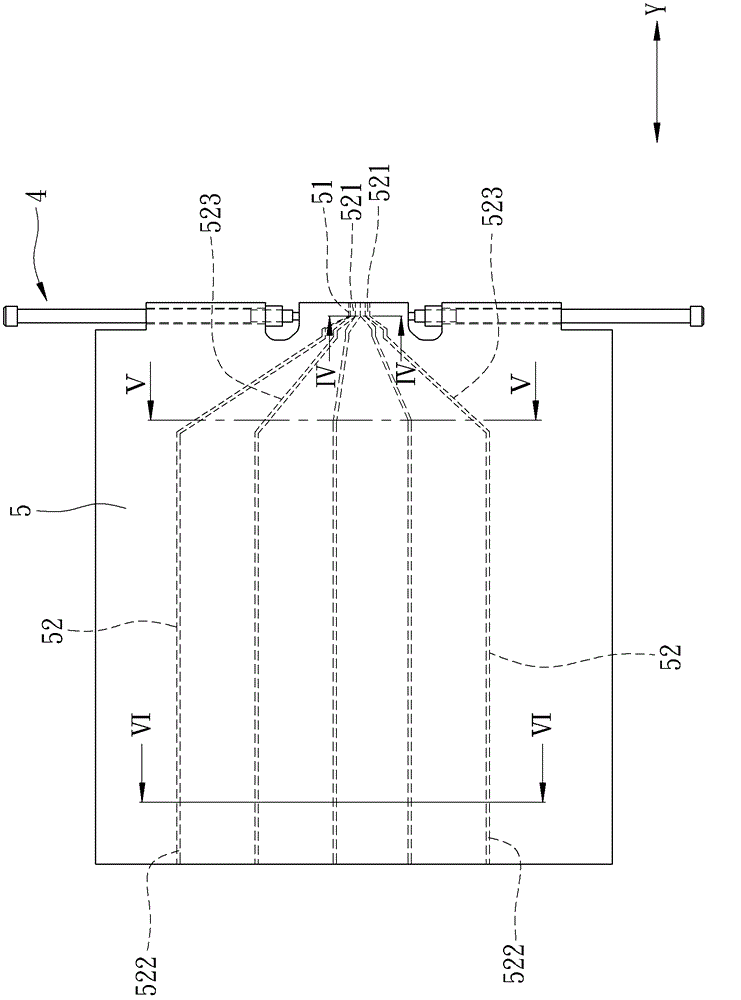

[0031] refer to figure 2 , 3 , a first preferred embodiment of the hollow plate forming method of the present invention is applied to a hollow plate forming device 4 and used to form a hollow plate 2 under pressure.

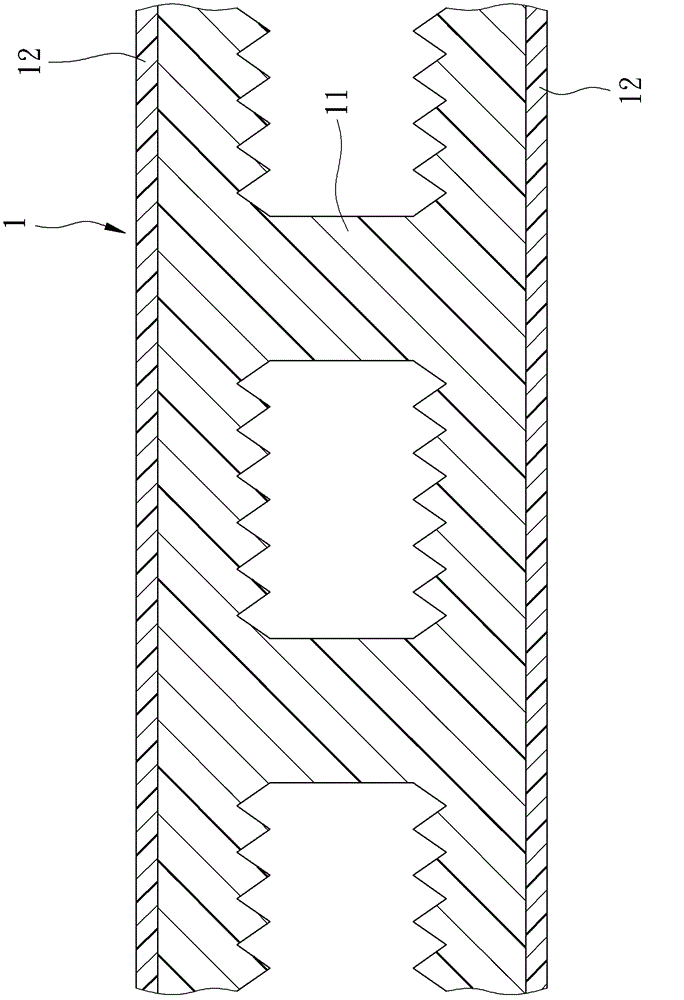

[0032] The hollow plate 2 includes a plurality of serially connected parts 3 connected in series toward a first direction X and extending toward a second direction Y perpendicular to the first direction X. In this embodiment, the cross section of each serial connection portion 3 is Z-shaped.

[0033] Each serial connection part 3 has two first board layers 32, two first board layers 32, two first board layers 32 arranged in sequence toward a third direction Z different from the first direction X and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com