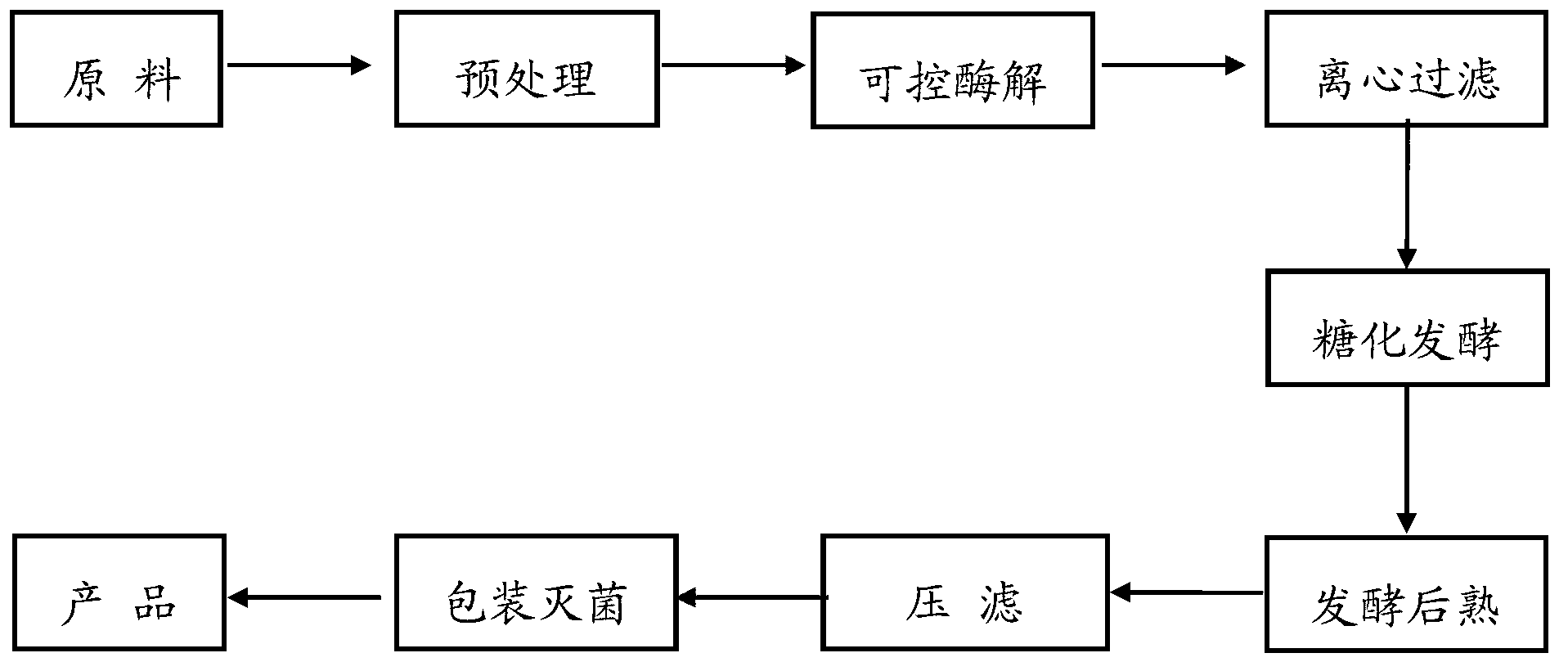

Novel saccharification-fermentation flavor fish sauce and preparation method thereof

A fish sauce and flavor technology, applied in the field of new glycofermented fish sauce and its preparation, can solve the problems of long production cycle, fishy smell, increased production process and processing costs, etc., to achieve rapid growth and saccharification and fermentation, Increase the added value of products and realize the effect of high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw material: 100kg of small miscellaneous fish;

[0027] step:

[0028] (1) Beat the small miscellaneous fish and mix it with 100kg of water to obtain a fish paste with a concentration of 50wt% (that is, the ratio of solid to liquid is 1:1), raise the temperature to 45°C, and add papain 250×10 5 U, enzymatic hydrolysis for 300 minutes, control the concentration of total solids to be 10wt%, after the completion of the enzymatic hydrolysis, heat up to 95°C, inactivate the enzyme for 15 minutes, and obtain the enzymatic hydrolysis product;

[0029] (2) Centrifuge the enzymatic hydrolysis product in a high-speed centrifuge at a speed of 5000r / min, filter through a 200-mesh sieve, remove solid residues, and obtain an enzymatic hydrolysis solution;

[0030] (3) Mix the enzymatic solution, salt, and sugarcane juice in a weight ratio of 1:0.25:0.03, place them in a fermenter, heat-preserve, saccharify and ferment at 40°C for 3 days to obtain a fermented liquid;

[0031] (4) Mi...

Embodiment 2

[0035] Raw material: blue round trevally 100kg;

[0036] step:

[0037] (1) Beat the blue squid and mix it with 150kg of water to obtain a fish paste with a concentration of 40wt%, raise the temperature to 55°C, add papain 300×10 5 U, enzymatic hydrolysis for 200 minutes, control the concentration of total solids to be 13.5wt%, after the completion of the enzymatic hydrolysis, heat up to 95°C, inactivate the enzyme for 15 minutes, and obtain the enzymatic hydrolysis product;

[0038] (2) Centrifuge the enzymatic hydrolysis product in a high-speed centrifuge at a speed of 5000r / min, filter through a 200-mesh sieve, remove solid residues, and obtain an enzymatic hydrolysis solution;

[0039] (3) Mix the enzymatic solution, salt, and sugarcane juice in a weight ratio of 1:0.3:0.02, put them in a fermenter, heat-preserve, saccharify and ferment at 50°C for 5 days, and obtain a fermented liquid;

[0040] (4) Mix the fermented liquid and the distiller's grain juice in a ratio of 1...

Embodiment 3

[0044] Raw material: 90kg of sardines;

[0045] step:

[0046] (1) Beat the sardines and mix them with 110kg of water to obtain sardines with a concentration of 45wt%, raise the temperature to 55°C, add papain 360×10 5 U, enzymatic hydrolysis for 150 minutes, control the concentration of total solids to 12.5wt%, after the completion of the enzymatic hydrolysis, heat up to 95°C, inactivate the enzyme for 15 minutes, and obtain the enzymatic hydrolysis product;

[0047] (2) Centrifuge the enzymatic hydrolysis product in a high-speed centrifuge at a speed of 5000r / min, filter through a 200-mesh sieve, remove solid residues, and obtain an enzymatic hydrolysis solution;

[0048] (3) Mix the enzymatic solution, salt, and sugarcane juice in a weight ratio of 1:0.3:0.02, put them in a fermenter, heat-preserve, saccharify and ferment at 50°C for 5 days, and obtain a fermented liquid;

[0049] (4) Mix the fermented liquid and the distiller's grain juice in a ratio of 1:0.1 by weight, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com