Ferrite composite and electronic part

A technology for electronic parts and compositions, applied in the field of ferrite compositions and electronic parts, to achieve the effect of reducing power loss and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21 and comparative example 1~10

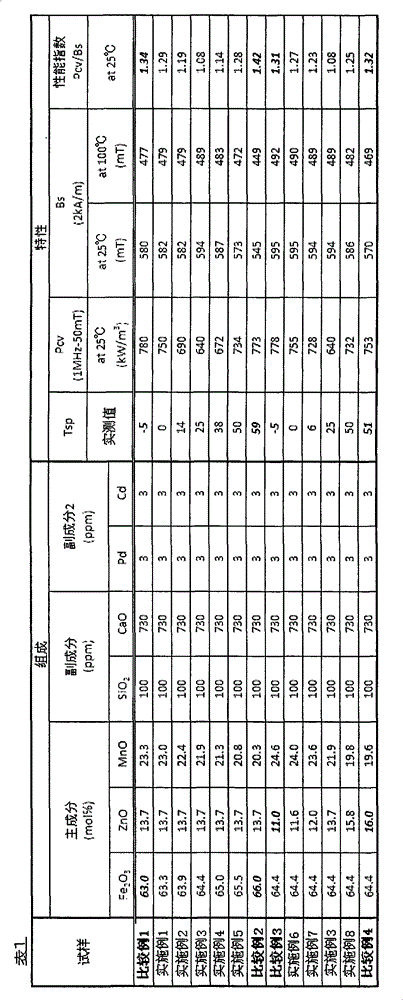

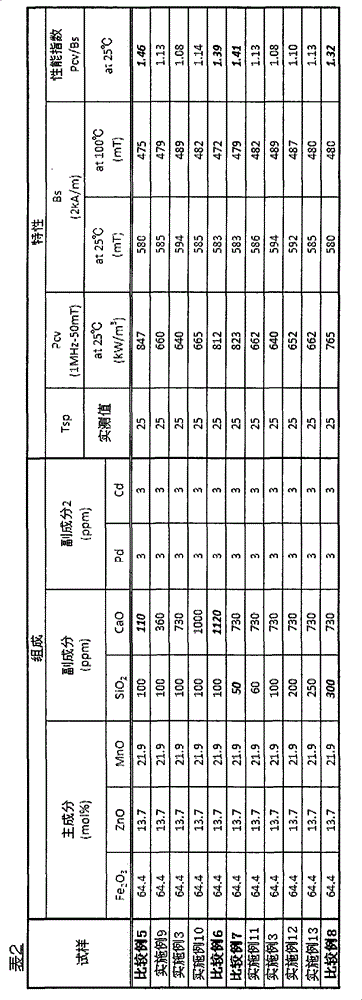

[0076] First, prepare the Fe 2 o 3 , ZnO and, Mn 3 o 4 Raw materials used as main components. Prepare SiO 2 and CaCO 3 Raw materials used as sub-components.

[0077] In addition, Pb and Cd are contained in iron oxide, zinc oxide, and manganese oxide which are raw materials of main components. Therefore, various raw materials of iron oxide, zinc oxide, and manganese oxide having different Cd and Pb contents were prepared, and the amounts used were adjusted so that the finally obtained samples contained the amounts of Cd and Pb described in Tables 1 to 3.

[0078] Next, the prepared raw material powder of the main component was weighed, and the raw material powder of the subcomponent was weighed according to the amount shown in Table 1, and wet mixing was performed for 5 hours with a ball mill to obtain a raw material mixture.

[0079] Next, the obtained raw material mixture was calcined in air at 950° C. for 2 hours to form a calcined material and then wet pulverized wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap