Method for regulating and designing engine jet pipe throat area by taking installation performance into account

An engine nozzle and area adjustment technology, which is applied in the direction of machines/engines, calculations, jet propulsion devices, etc., can solve problems such as the difference in engine rear body resistance, limit the installation performance of the propulsion system, and achieve the effect of improving the installation thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

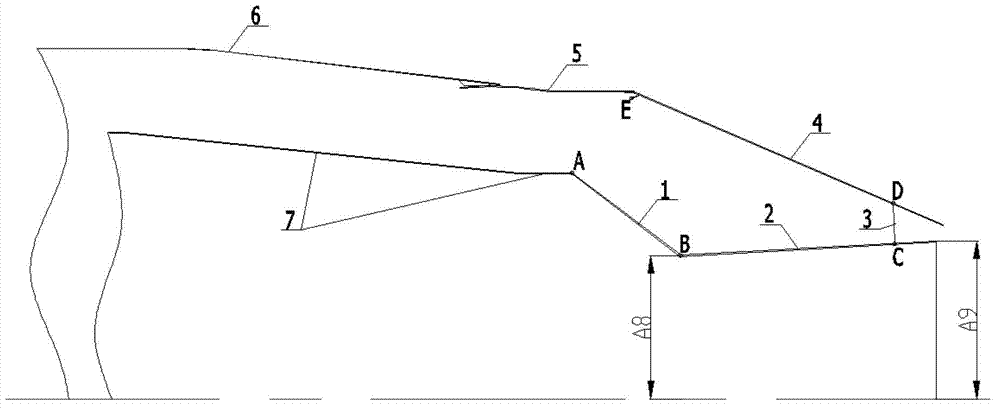

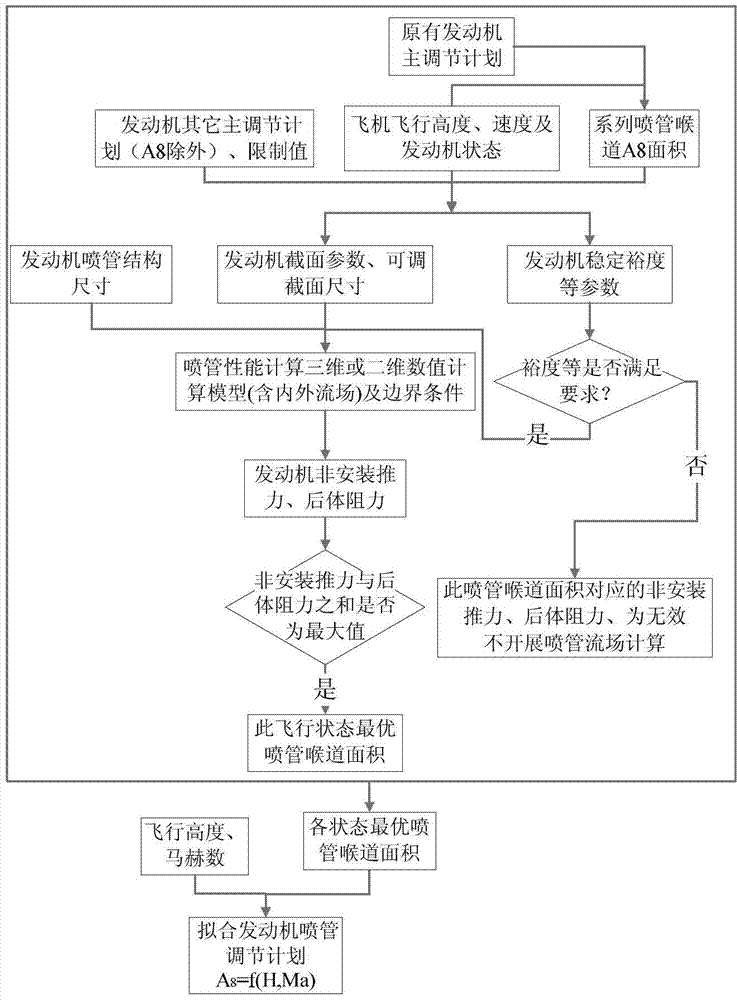

[0013] This embodiment provides a design method for adjusting the throat area of the engine nozzle considering the installation performance, which is characterized in that: the design method for adjusting the throat area of the engine nozzle considering the installation performance is as follows:

[0014] According to the flight altitude, Mach number and engine state, the engine main adjustment plan considering the non-installation performance is used to determine the nozzle throat area required by the engine at this time, and 70% of this area is taken as the minimum area, and 130% of this area % is taken as the maximum value, and is divided into a series of nozzle throat areas, which are divided into 10 equal parts; based on the engine master adjustment plan, engine limit value and series nozzle throat area, use engine zero-dimensional calculation software (such as turbotrans, etc.) Calculate the corresponding engine section parameters, adjustable section size, and engine ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap