A device for reversely erasing viscous fluid substances on the surface of a soft roller by using a hard roller

A roller surface, soft technology, applied in the general parts of printing machinery, printing, printing machines and other directions, can solve the problems of poor consistency, serious reliability and efficiency, and poor effect of scraping off the surface of the plate roller. The effect of expanding the range of use and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

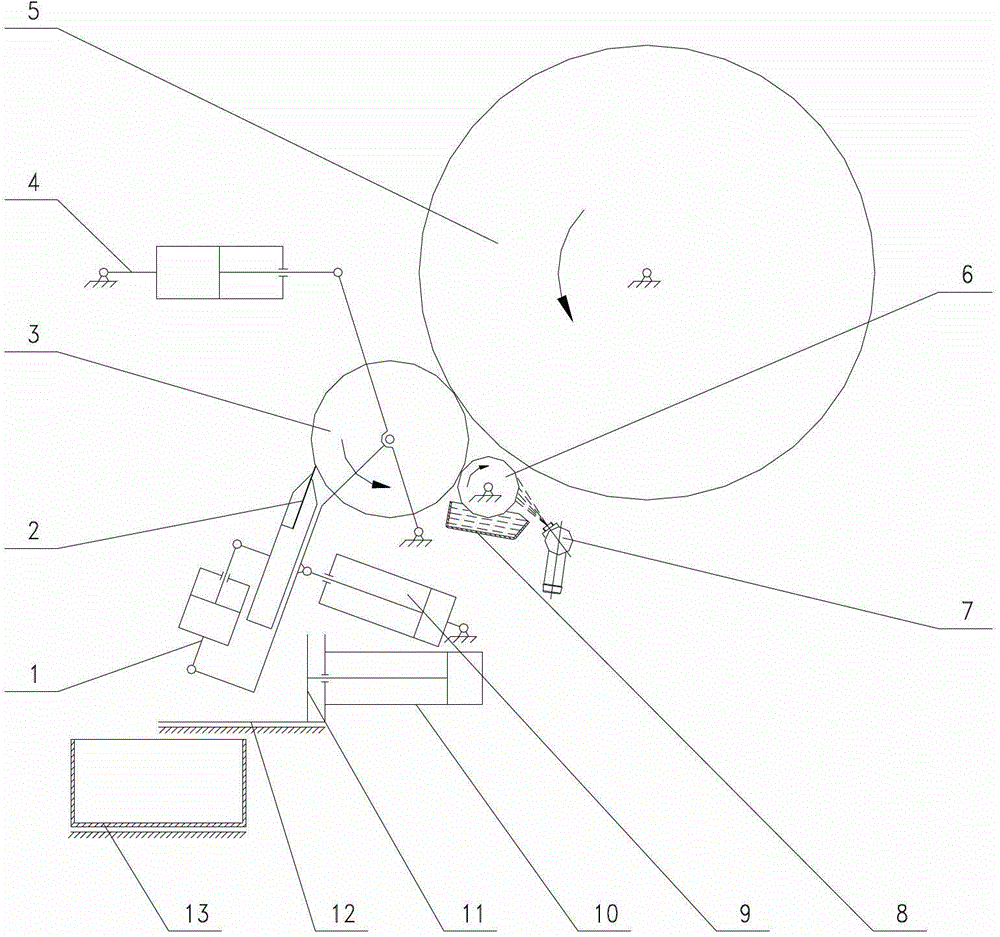

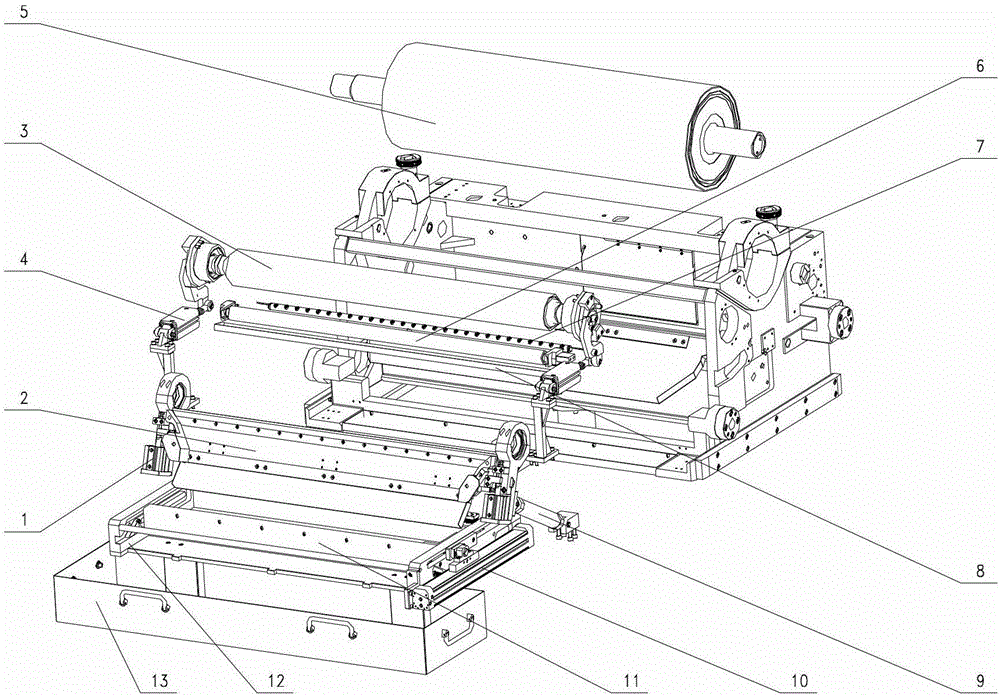

[0016] The device of this embodiment adopting the hard roller to reversely wipe the viscous fluid substance on the surface of the soft roller is as follows: figure 1 and figure 2 As shown, the ink scraping blade 2 faces upwards, is placed on the blade frame and forms a moving pair with the blade frame, one end of the blade frame is hinged with the cylinder body of the ink scraping clutch cylinder 1, and the piston rod of the ink scraping clutch cylinder 1 is connected to the scraping ink clutch cylinder 1. The ink blade is hinged so that the doctor blade 2 has a forward and a retracted position. When the doctor blade 2 is in the forward position driven by the piston rod, the blade edge is in line contact with the metal counter rubbing roller 3 at a contact angle of 120°. In order to facilitate the disassembly and assembly of the doctor blade 2, the bottom surface of the knife rest is hinged with the piston rod of the knife rest clutch cylinder 9, and the cylinder body of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com