Quality analysis device and method for banknote product

A product quality and analysis device technology, applied to instruments, handling coins or valuable banknotes, etc., can solve the problems of low production efficiency, high price, no printing code and final quality inspection of large products combined into one

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

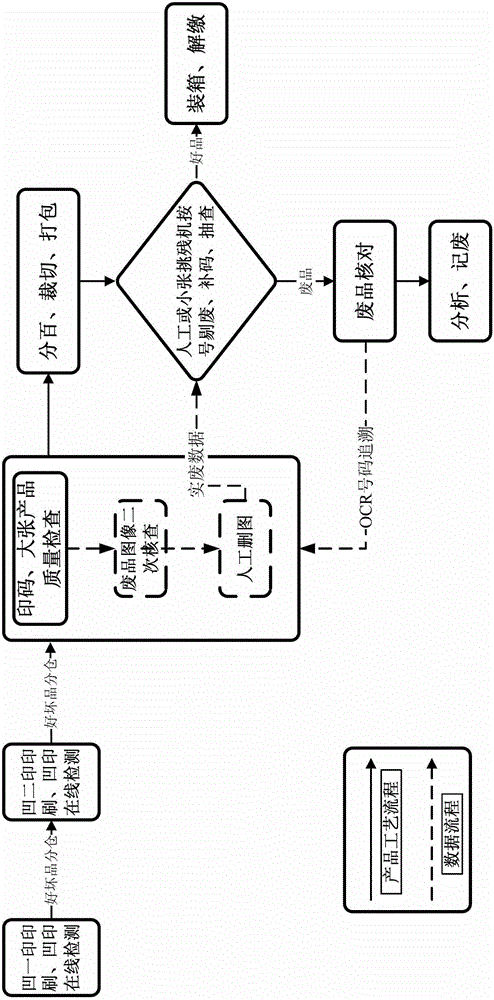

[0017] Banknote product quality analysis method flow process provided by the present invention is as follows figure 1 As shown, in the gravure printing process of banknote products, the gravure online secondary verification system is added to separate the good and bad products into warehouses, so as to ensure that the waste products in the tens of thousands of products are relatively concentrated before printing code printing, so as to reduce the waste in the later process. Amount of waste unpacked. Utilize the paper feeding part and code printing part of the multi-functional code printing machine, and install a newly designed detection part and paper delivery part in the rear part, and upgrade the relatively mature three-in-one online detection system for printing and code printing to an embossed large-sheet combined machine , to realize the full inspection of the quality of the large banknotes after the banknotes are printed and coded through the machine vision inspection te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com