Intelligent curing system for crystalline silicon photovoltaic module

A technology of photovoltaic modules and crystalline silicon, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of many hidden dangers in the curing quality, achieve the effect of realizing fully automatic assembly line operation, facilitating production management, and ensuring the quality of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

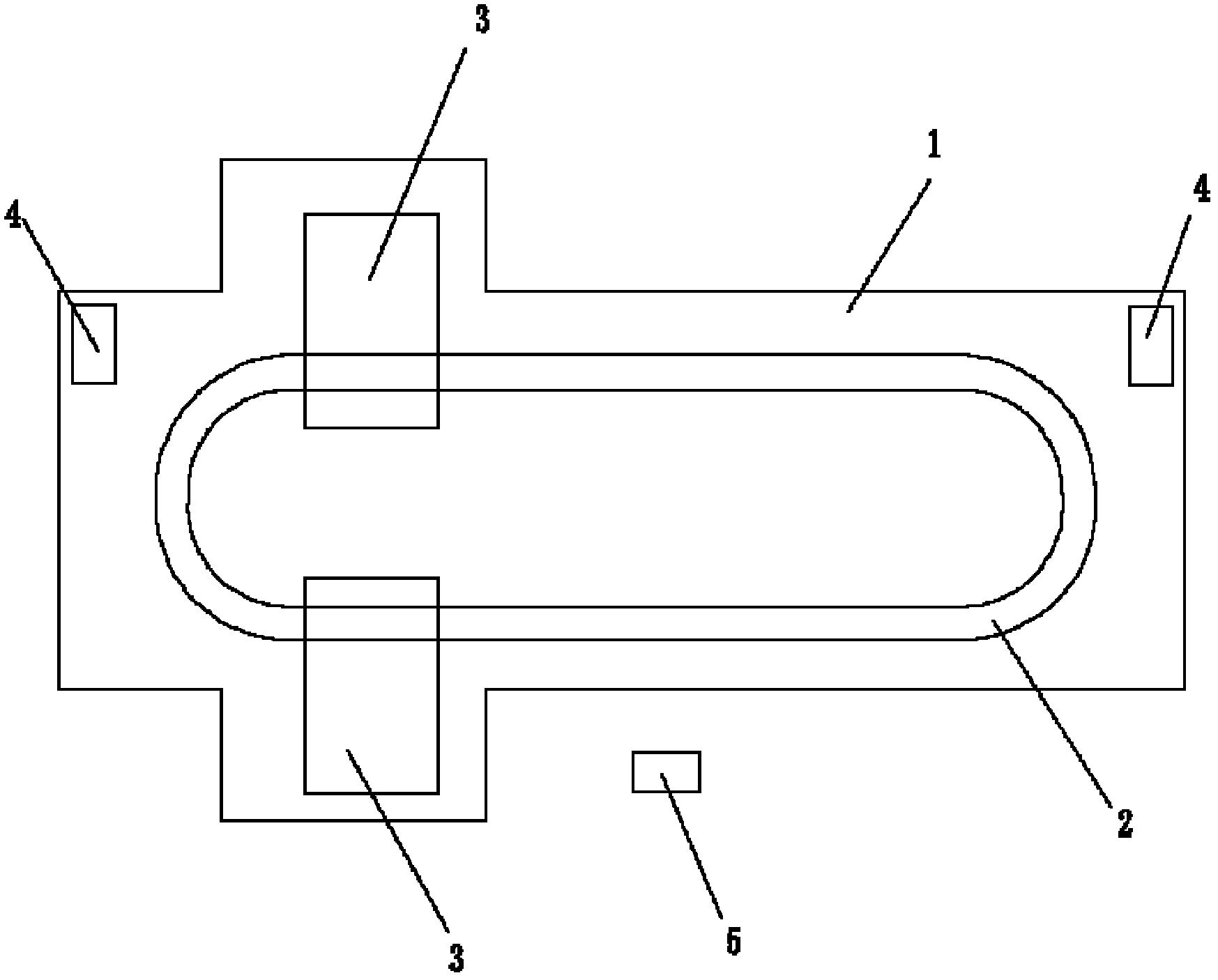

[0039] See figure 1 , the intelligent curing system for crystalline silicon photovoltaic modules in this embodiment includes a curing chamber 1 , an automatic module curing conveyor 2 , a module conveying device 3 , a constant temperature and humidity system 4 and a control mechanism 5 . The curing room 1 is a closeable room, which is provided with an entrance 11 and an exit 12; the component curing automatic conveyor 2 is set on the ground in the curing room 1; there are two component transmission devices 3, which are respectively set on the component curing automatic conveyor The position of the upper and lower components of 2; the constant temperature and humidity system 4 is set in the curing room 1; the control mechanism 5 is set outside the curing room for controlling the curing room.

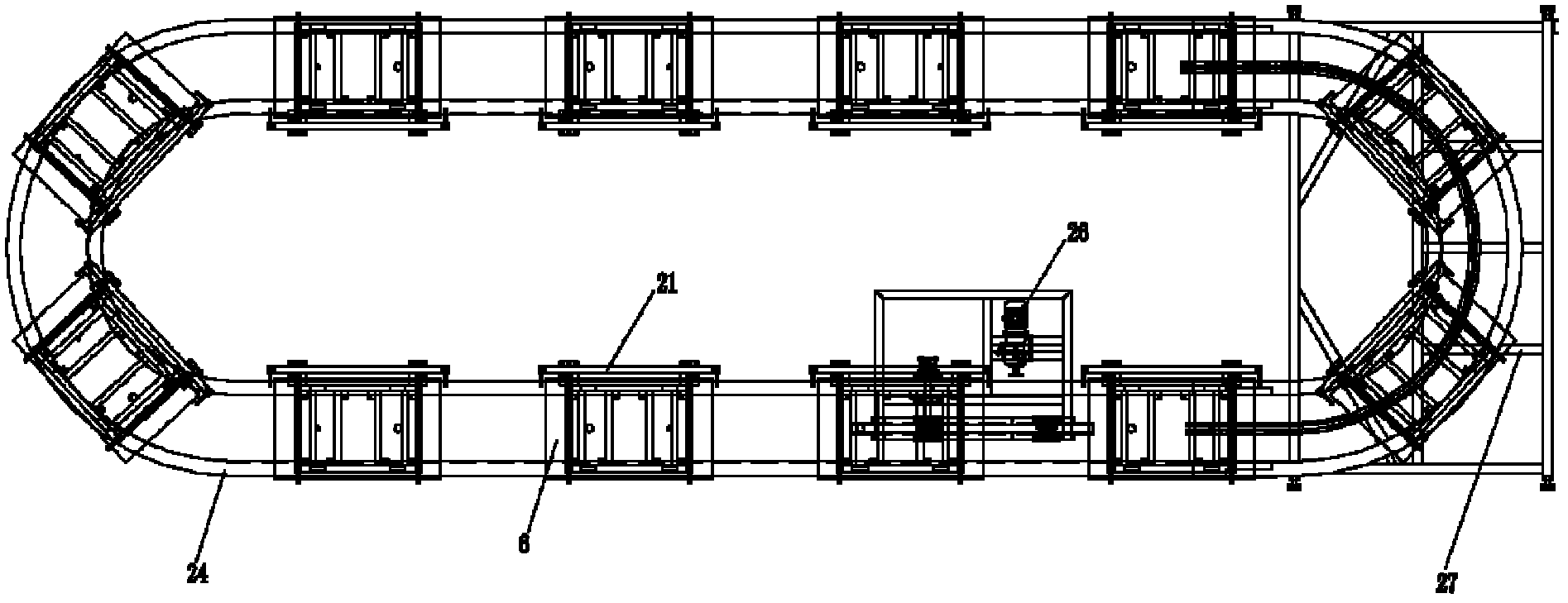

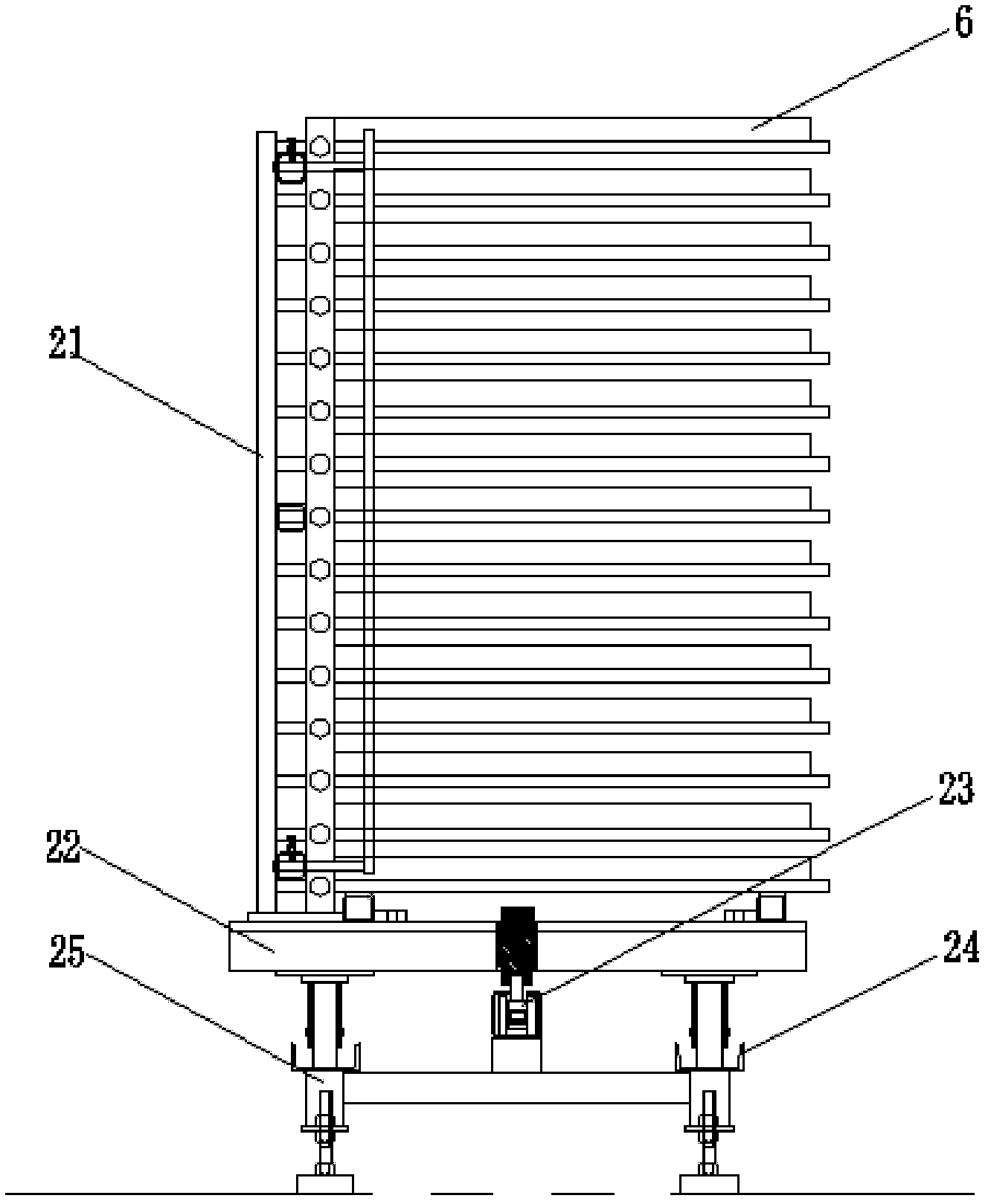

[0040] See Figure 2 to Figure 5The component curing automatic conveyor 2 includes a component storage rack 21, a carrying trolley 22, a traction chain 23, a track system 24, a mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com