Execution mechanism for dry-type dual-clutch automatic transmission rack

An automatic transmission and dual clutch technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of low control accuracy, high cost, and difficulty in implementation.

Active Publication Date: 2014-12-10

TONGJI UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this mechanism also has defects such as high cost, difficulty in realization, and low control precision.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

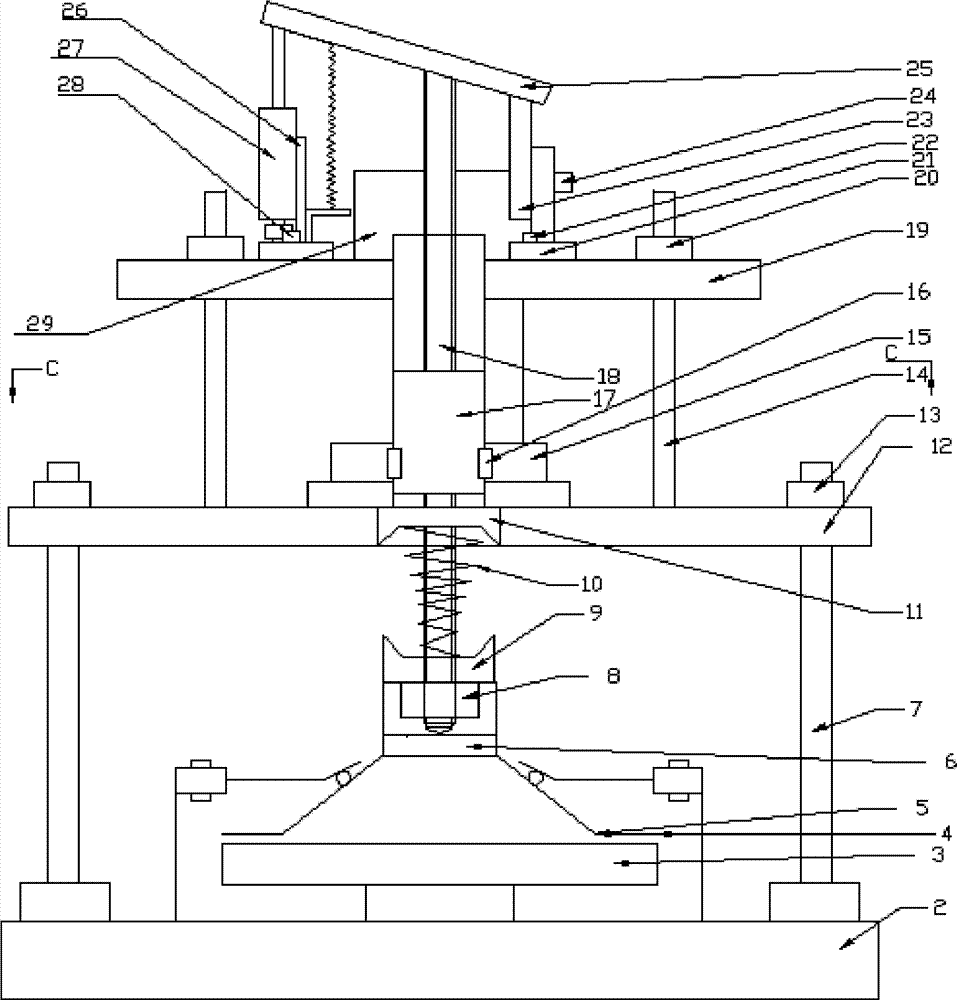

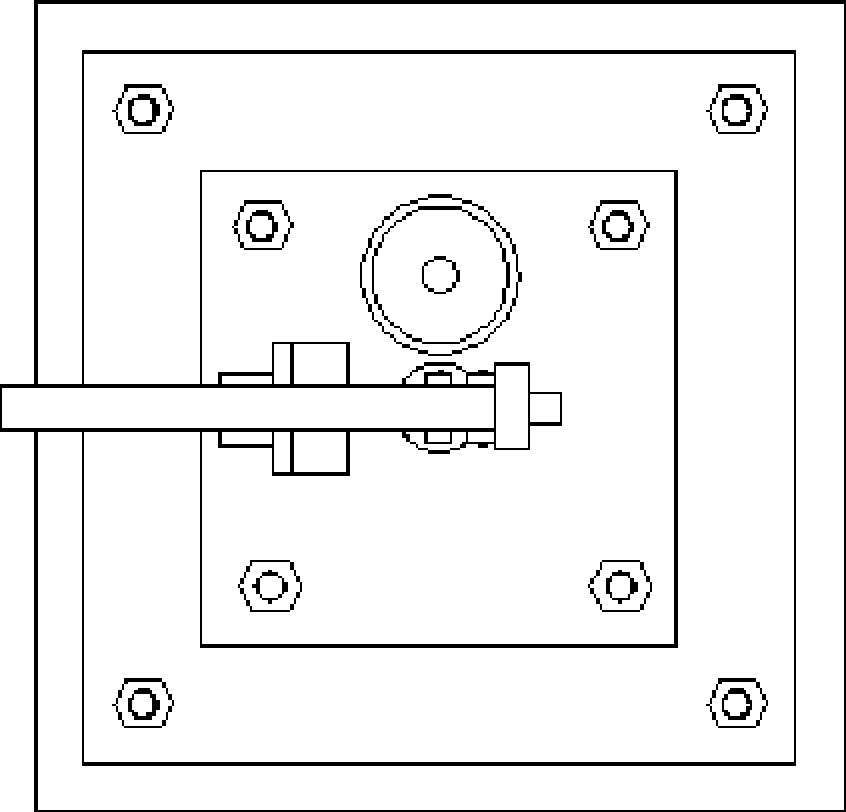

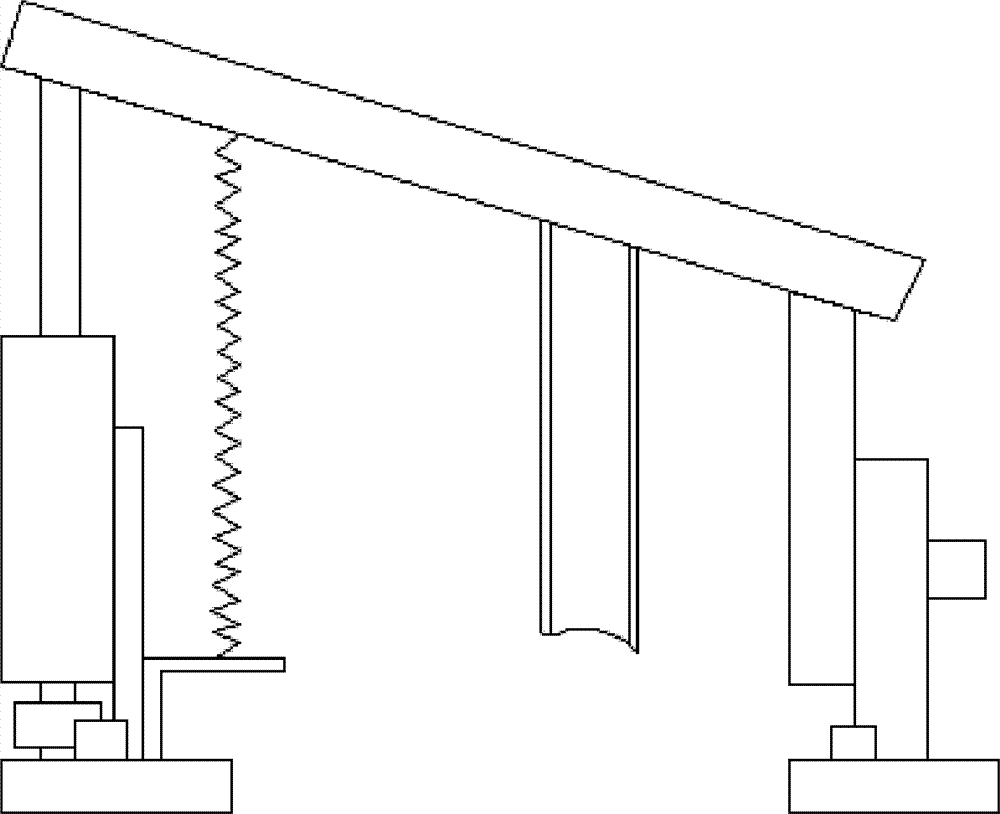

[0037] Such as Figure 1-Figure 5 As shown, an actuator for a dry double clutch automatic transmission bench, including:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an execution mechanism for a dry-type dual-clutch automatic transmission rack. The execution mechanism comprises a test platform (2), a bearing carrier pressure plate (3), a clutch diaphragm spring (5), a clutch separation bearing, a lower support plate (12), a transmission screw (18), a transmission nut (17), a first transmission gear (15), a second transmission gear (1), an upper support plate (19), a drive motor (29) and a displacement amplifying component. Compared with the prior art, the execution mechanism provided by the invention has the advantages of actually simulating the actuation process of a dry-type dual clutch transmission (DCT) to reflect the dynamic characteristics of a clutch execution mechanism of a real vehicle, etc.

Description

technical field [0001] The invention relates to a technology related to a dry double-clutch automatic transmission, in particular to an actuator for a dry-type double-clutch automatic transmission stand. Background technique [0002] The dual-clutch automatic transmission (DCT) can ensure that the power output is not interrupted during the shifting process, which is conducive to improving the shifting quality. At present, DCT clutch actuators mainly have three structural forms: electronically controlled pneumatic, electronically controlled hydraulic and electronically controlled electric. The electronically controlled electric actuator has the advantages of fast response, simple structure, high transmission efficiency, and low manufacturing cost. widely used. [0003] A typical electronically controlled electric clutch actuator has two structures, one is mainly composed of a DC motor, a helical transmission mechanism, a helical booster spring, a hydraulic transmission mecha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M13/02

Inventor 赵治国章桐胡笑天刁威振彭玉钢

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com