Symmetric three-freedom-degree rotary parallel mechanism without intersecting axes

A technology without converging axes and degrees of freedom, applied in manipulators, program-controlled manipulators, metal processing machinery parts, etc., can solve problems such as difficulty in ensuring machining accuracy and difficulty in manufacturing, and achieve guaranteed machining accuracy, easy machining accuracy, and branching The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

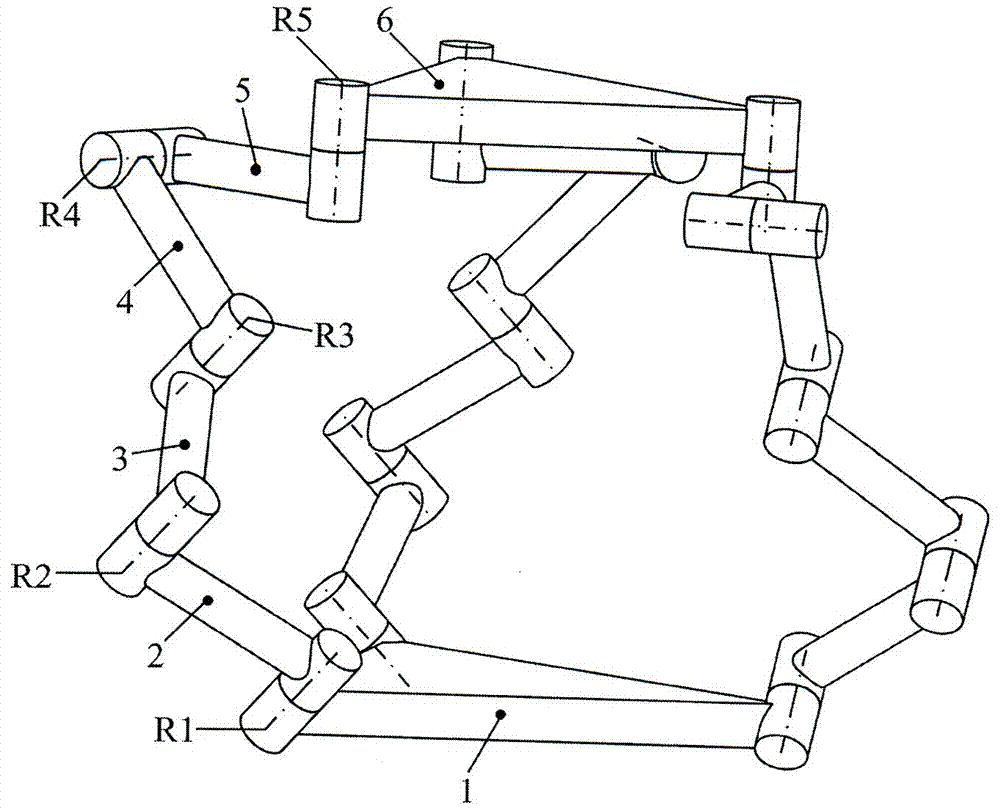

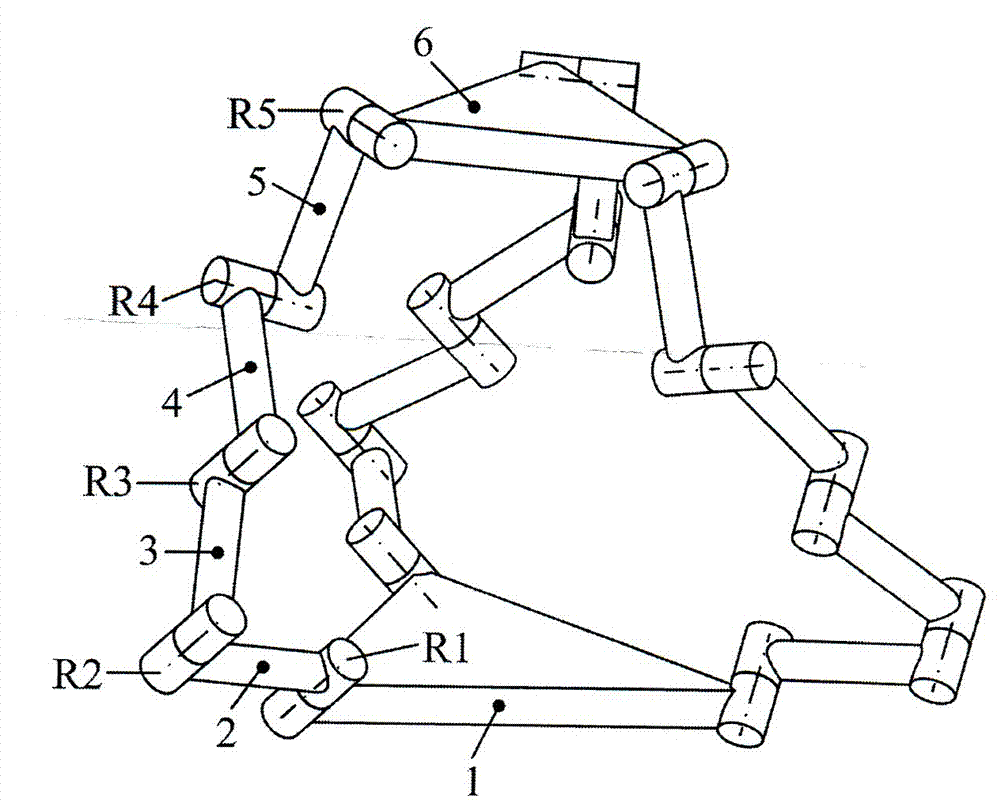

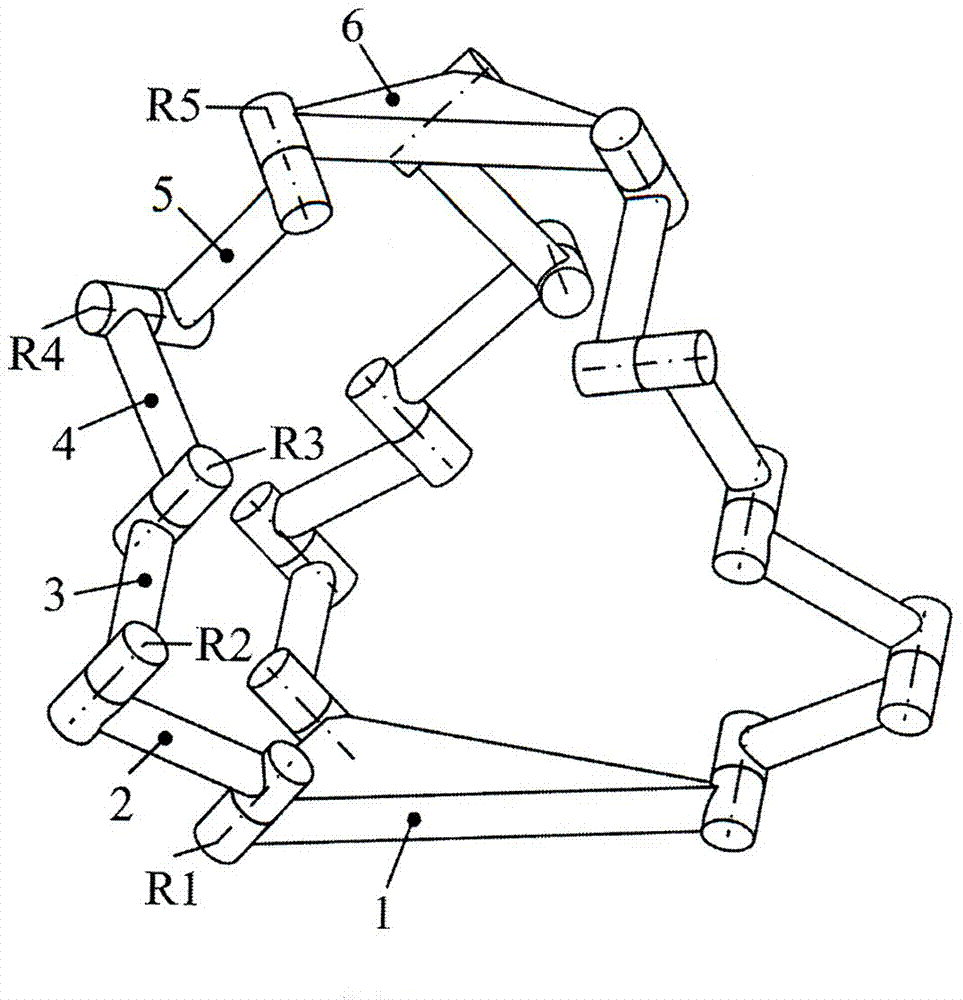

[0023] exist figure 1 In the three-degree-of-freedom rotating parallel mechanism embodiment 1 shown without converging axes, the parallel mechanism is composed of a fixed platform 1, a moving platform 6 and three movable branches with identical structures, and each movable branch consists of two A revolving pair and a three-degree-of-freedom planar sub-chain are composed of three revolving pairs R1, R2, and R3 whose axes are parallel to each other. The revolving pair R1 connects the fixed platform 1 and The connecting rod 2 is arranged obliquely with the fixed platform. The rotating pair R2 connects the connecting rod 2 and the connecting rod 3, the rotating pair R3 connects the connecting rod 3 and the connecting rod 4, and the rotating pair R4 connects the connecting rod 4 and the connecting rod 5. The rotating pair The axis of R4 and the axis of the rotating pair R3 are not parallel to each other, the rotating pair R5 is connected to the connecting rod 5 and the moving pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com