Bag collecting device

A technology of bag collection and bag collection wheel, which is applied to bag opening sewing machines, textiles, papermaking, sewing equipment, etc., can solve the problems of irregular bag collection, no bag collection device, and low production efficiency, and achieve fast bag collection speed, Neat bag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following examples are only used to illustrate the technical solutions of the present invention, but do not limit the present invention.

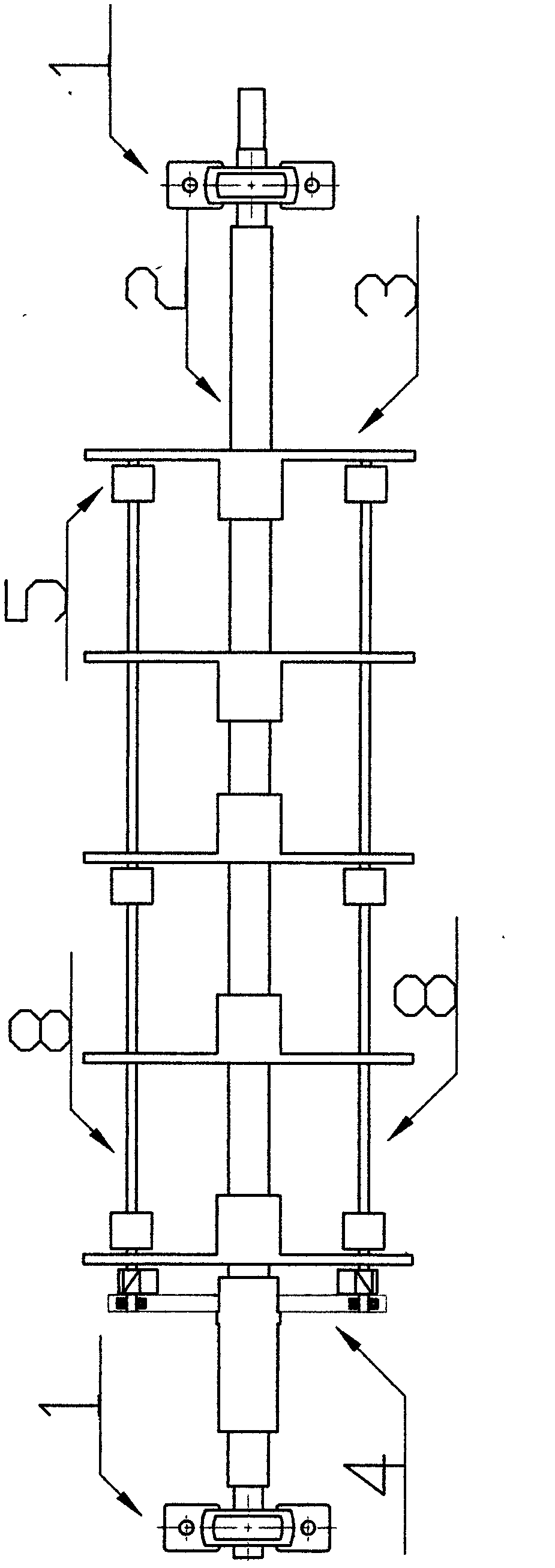

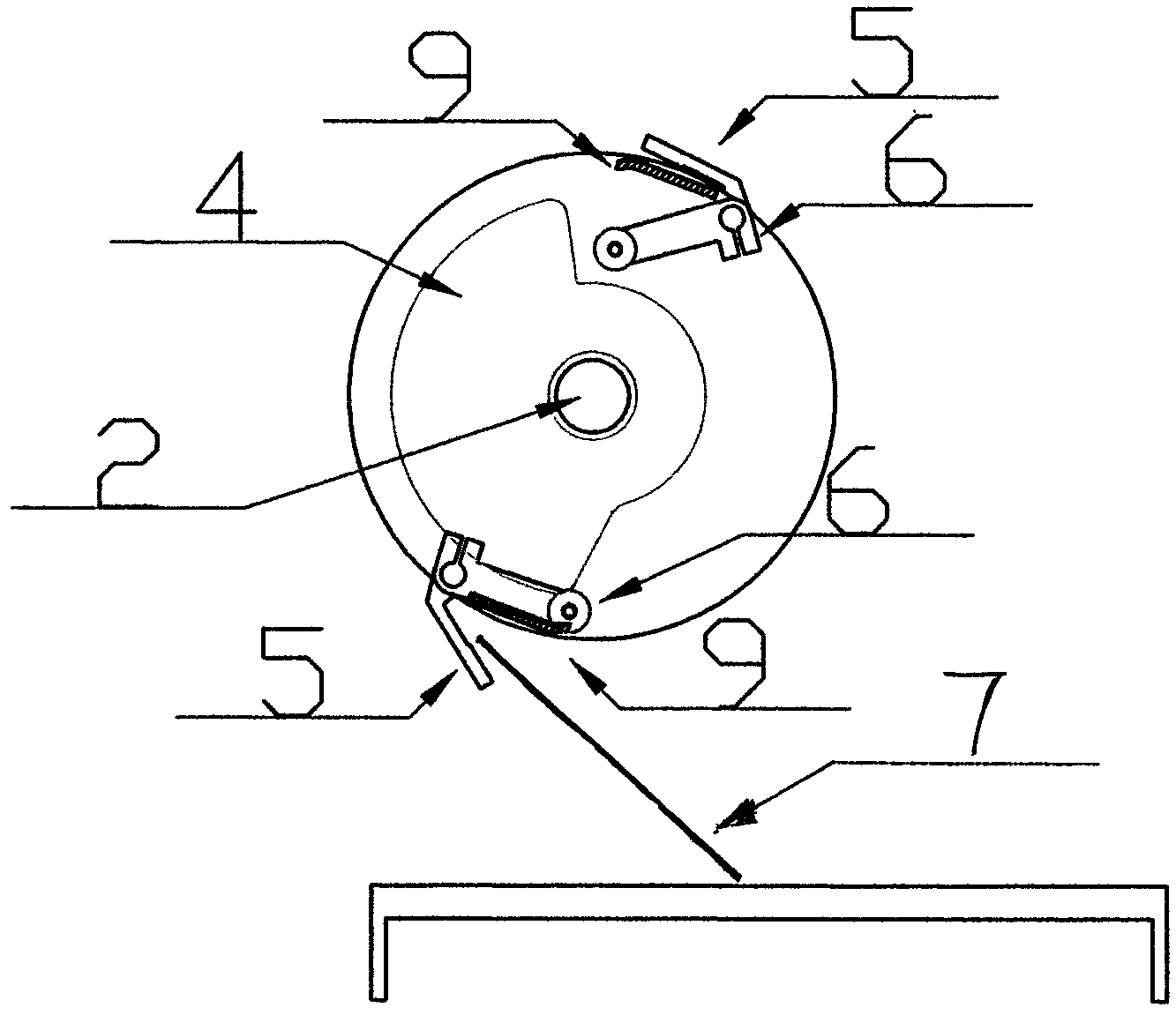

[0009] The bag collection device includes a main shaft 2, two connecting shafts 8, two bearings 1 and a plurality of bag collection wheels 3, the two bearings 1 are distributed at two ends, the main shaft 2 is installed in the middle of the two bearings 1, and the intervals on the main shaft 2 are evenly spaced. A plurality of bag collection wheels 3 are installed, and a plurality of bag collection wheels 3 outer peripheries are connected as a whole with two connecting shafts 8; a cam 4 is housed in the main shaft center of one of the bag collection wheels 3 outsides on the limit; The shaft 8 is equipped with a pair of presser feet symmetrically moving up and down. The presser feet are in the shape of an open common stapler. There is a gland 5 on the top. Base plate 9 is housed on the bag receiving wheel 3 limits between 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com