Multifunctional self-loading/unloading equipment

It is a self-loading and multi-functional technology, which is applied in the direction of loading and unloading vehicle arrangement, transportation and packaging, and vehicles used for freight transportation. It can solve the problems of low safety, manual cargo handling, and affecting the loading capacity of trucks. pack neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

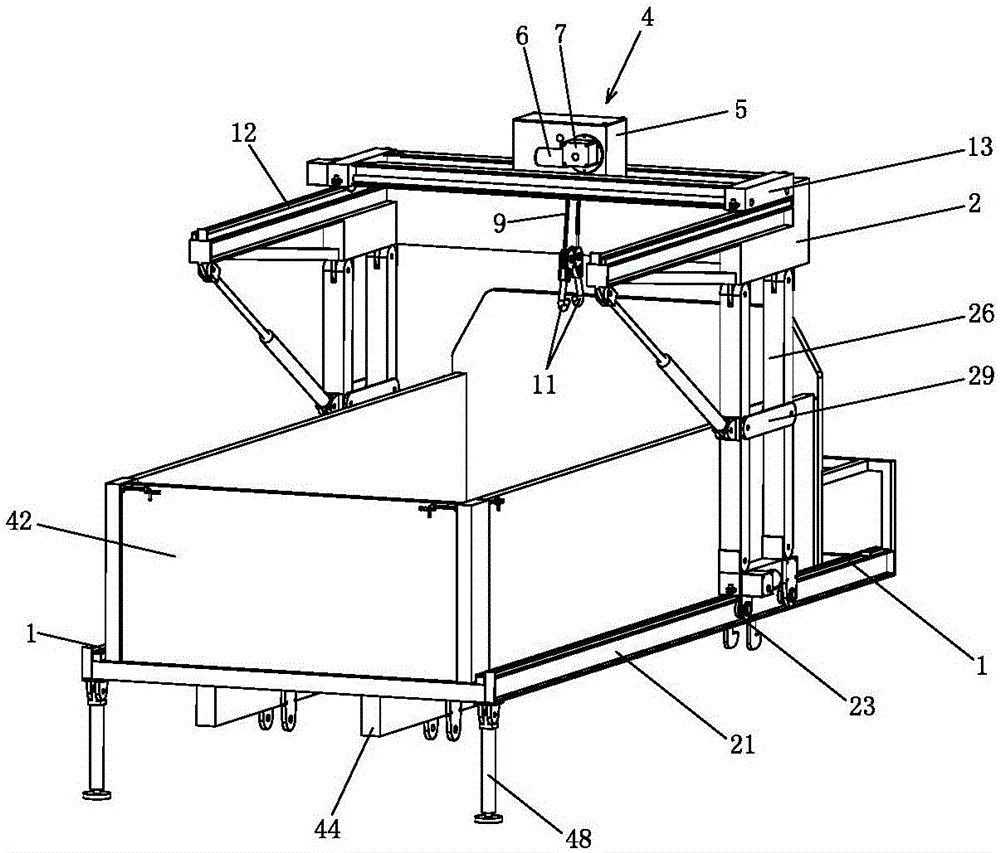

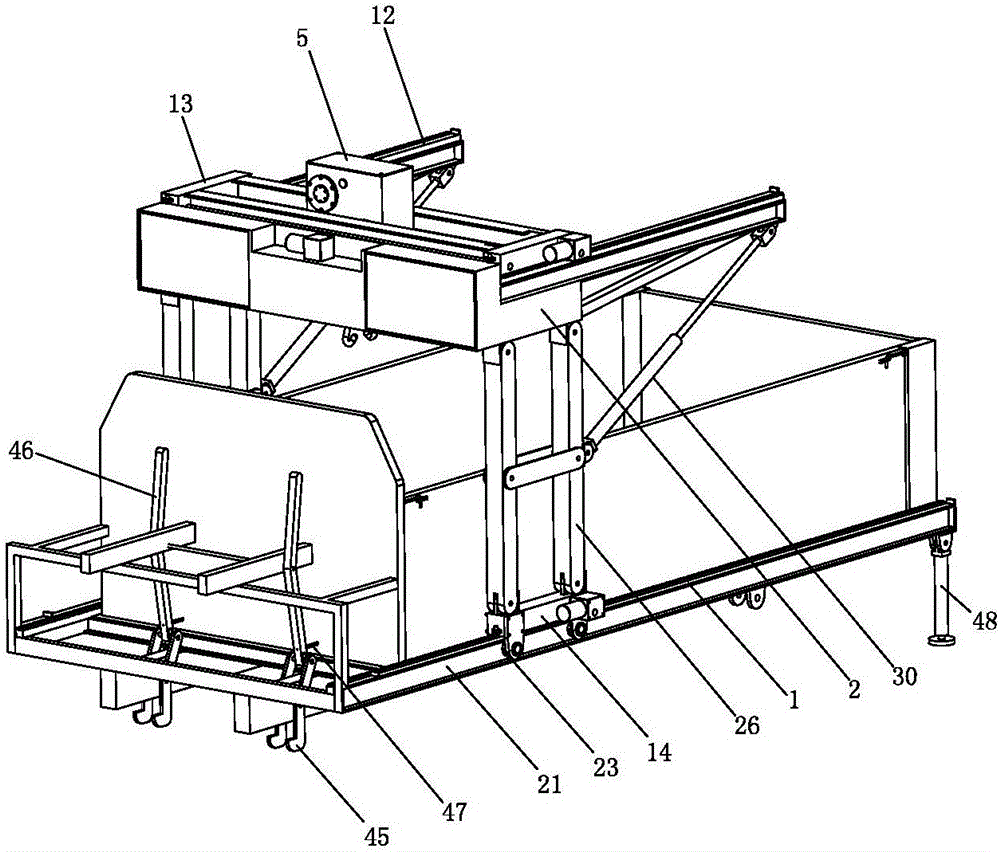

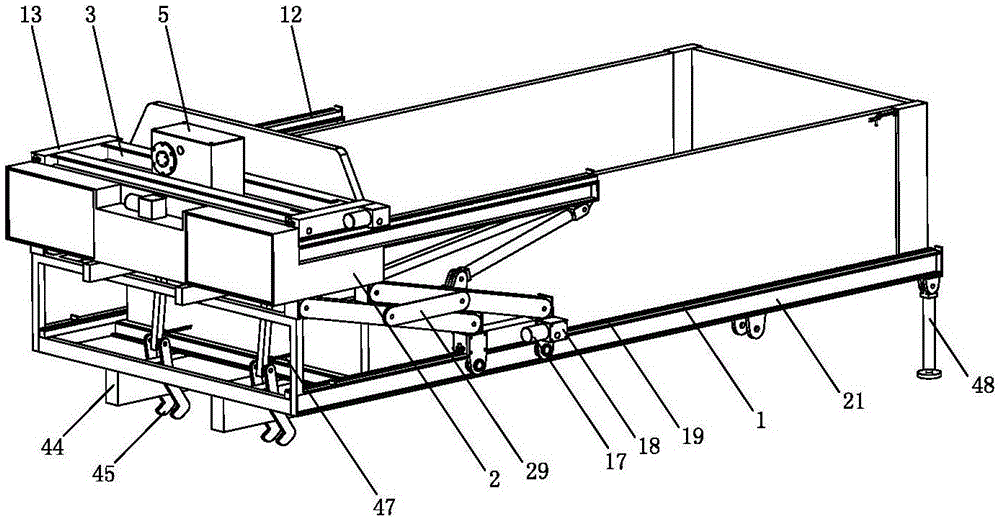

[0052] like figure 1 , figure 2 , image 3 and Figure 4 The lower part of the bottom plate 43 of the shown truck compartment 42 has two compartment girders 44 extending forward and backward, and a truck girder penetrating through the vehicle body is also provided between the two compartment girders 44 .

[0053] like Figure 1-4 The multifunctional self-loading and unloading equipment shown includes two main rails 1 arranged parallel to each other and a support frame one 2 straddling the two main rails 1, and a support frame for driving the support frame is arranged between the support frame one 2 and the main rail 1 A driving structure that moves synchronously along the two main rails 1. The support frame 2 has a secondary rail 3 that is perpendicular to the primary rail 1, a lifting device 4 that is located on the secondary rail 3, and is located on the lifting device 4 and the secondary rail. The driving structure two between the guide rails 3 is used to drive the lif...

Embodiment 2

[0076] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that this self-loading and unloading equipment is used on a container truck, wherein the main rail 1 is located on both sides of the top of the truck compartment 42 and runs along the top of the truck compartment. 42 extends lengthwise. At this time, there is no need to set the support column 26, and the support frame 1 is directly arranged on the main rail 1, and is connected to the main rail 1 through the driving structure 1. The structure of the driving structure 1 is the same as that of the first embodiment.

Embodiment 3

[0078] The structural principle of this embodiment is basically the same as the structural principle of Embodiment 1. The difference is that this self-loading and unloading equipment is used on a large vehicle that does not have reverse. Since the large vehicle cannot reverse the compartment, there is no need to set a swing hook. 45, shift fork 46 and extension spring 47 etc. That is to say, the self-loading and unloading equipment does not need to be put down, and can be directly moved to the front end of the truck compartment 42 when not in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com