High-capacity cartridge magazine and method

A large-capacity, magazine-based technology, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of heavy weight, no obvious advantages in the number of ammunition carried, and insufficient firepower persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

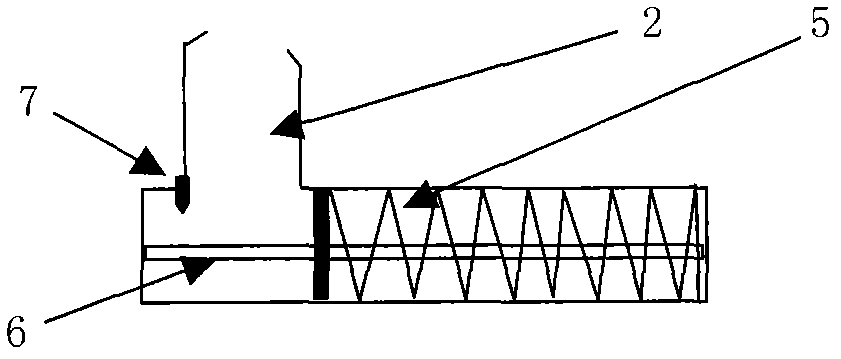

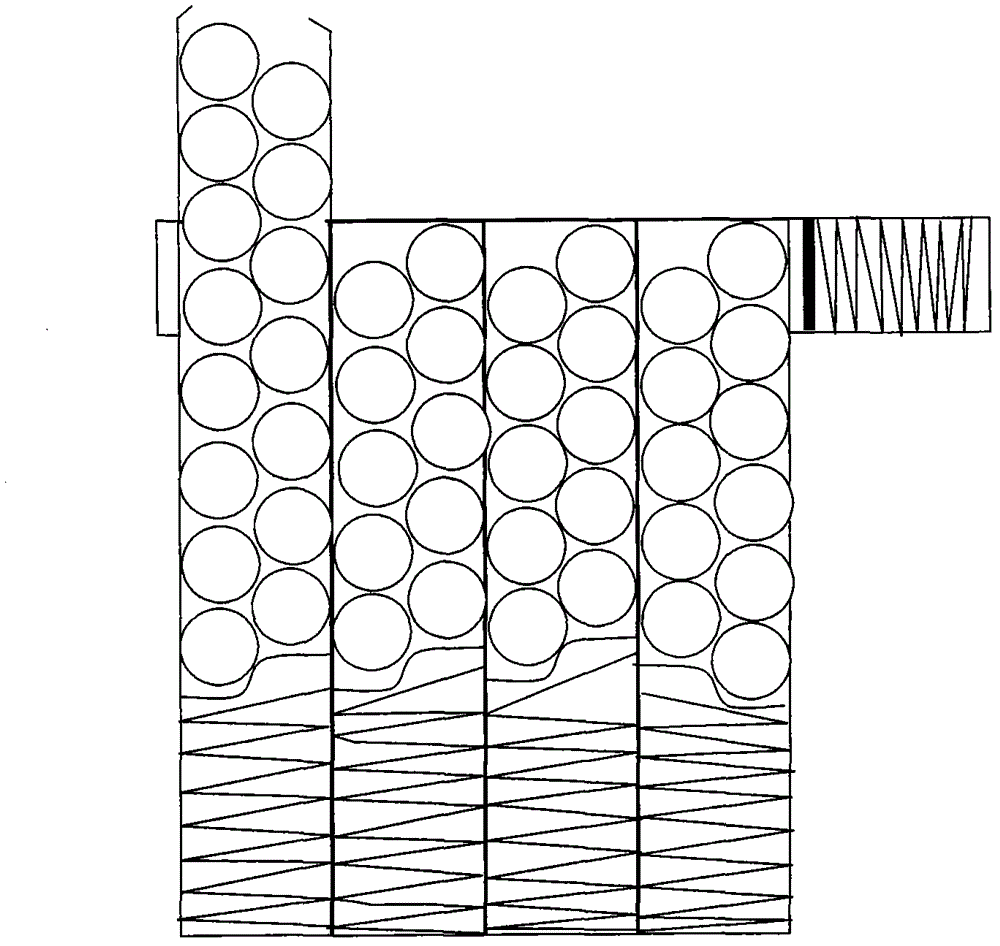

[0017] When reloading, press the bullet directly from the holding port, when the fourth magazine is full of bullets, push the magazine group to the right, so that the magazine group moves to the right along the guide rail, remove the magazine sleeve cover The five to six bullets in the magazine do not move (this number should be fixed according to the actual situation, such as the height requirement of the bullet port), and the bullets in the fourth magazine and the magazine group move to the right at the same time. When the buckle is in place, the third magazine is perpendicular to the holding port, and the pressing operation can be continued. By analogy, all the bullets can be fully pressed together with the magazine sleeve cover 2 in the four magazines. Please refer to image 3

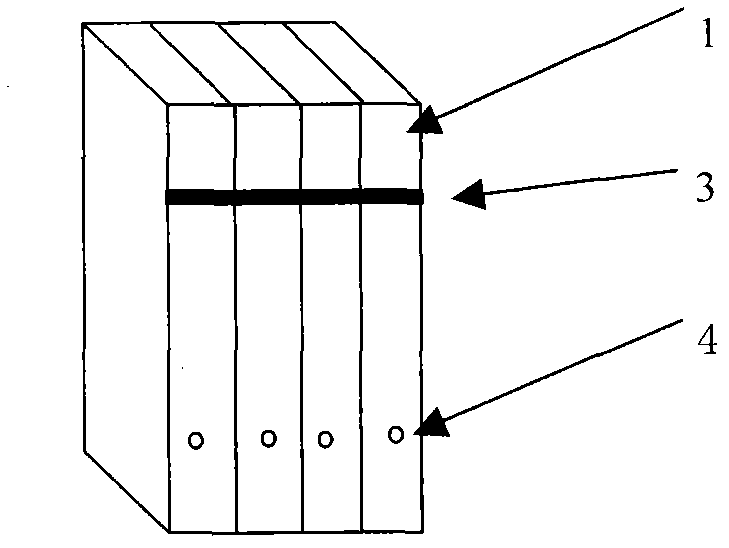

[0018] The internal width of the four separate magazines is tentatively determined to be 23mm, and the three inner partitions plus the magazine plates on the left and right sides, calculated acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com