Powered below-knee prosthesis

A power and prosthetic technology, applied in the fields of prosthesis, medical science, artificial legs, etc., can solve the problems of unnatural walking speed, stiffness of the forefoot and heel, and easy fatigue of amputees, so as to meet the needs of deformation and good energy storage. and shock absorption, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

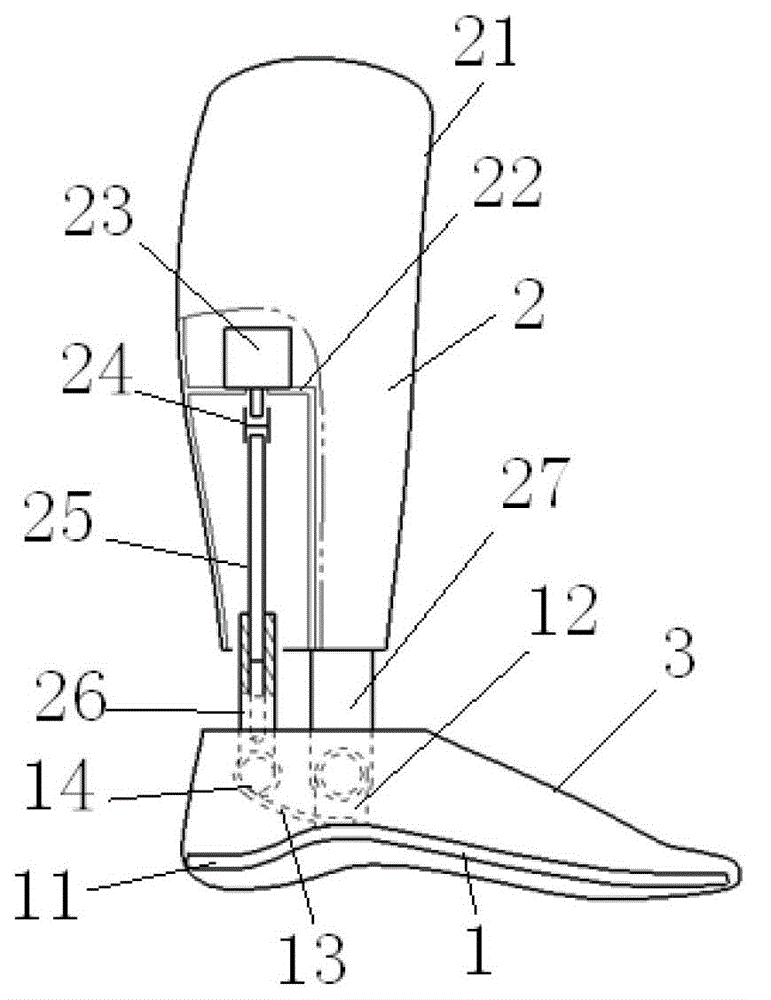

[0014] like figure 1 As shown, the present invention includes a prosthetic foot 1 and a calf prosthesis 2, and may also include a foot cover 3 wrapped outside the prosthetic foot 1.

[0015] The prosthetic foot plate 1 of the present invention comprises a foot plate 11, the middle part of the foot plate 11 has a higher arch, and a seat 12 is fixedly arranged on the top surface of the foot plate 11 at the arched part. The rear portion of the foot plate 11 is provided with an upwardly curved elastic connecting rod 13, the front portion of the elastic connecting rod 13 is fixedly connected to the top of the arched part of the foot plate 11, and an elastic movable space is arranged between the rear portion of the elastic connecting rod 13 and the foot plate 11. And another support 14 is fixedly arranged on the top of the rear end of the elastic connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com