Passive visual sensor based on weld automatic tracking of welding robot

A visual sensor and welding robot technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of unfavorable small-angle weld welding, large sensor volume and weight, unfavorable welding, etc., to facilitate installation and maintenance, The effect of great flexibility and expandability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

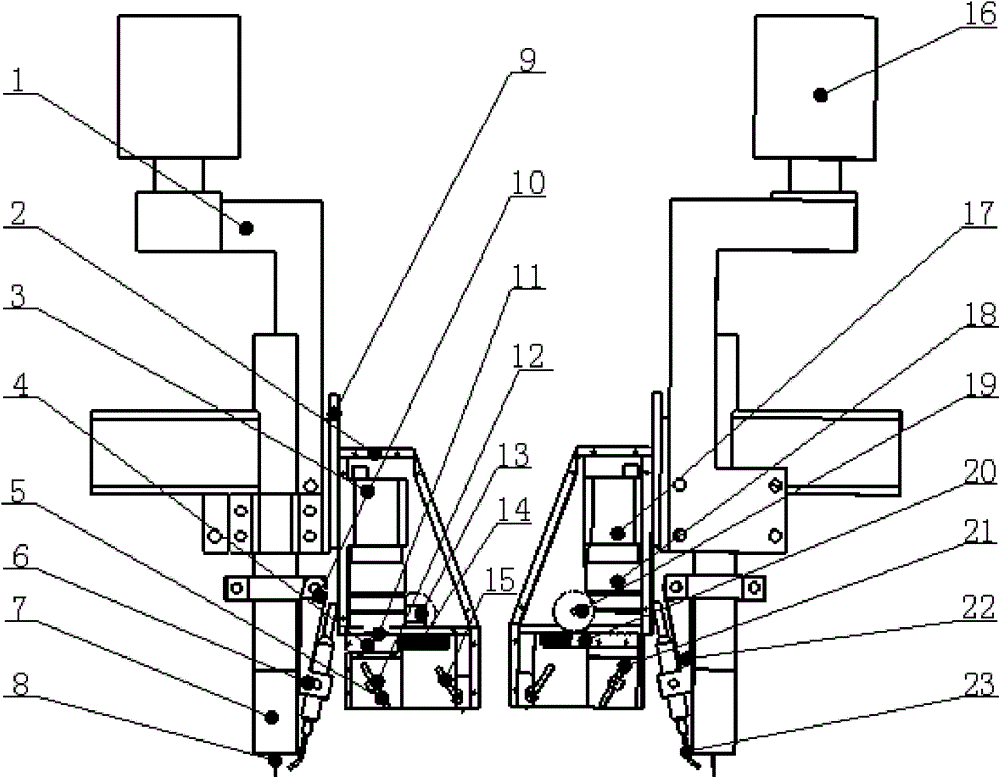

[0020] Such as figure 1 As shown, this embodiment includes: a mounting bracket 1, a system housing 2, a camera 3, a light reduction filter system 4, a light reflection system 5 and a wire feeding adjustment mechanism 6, wherein: the camera 3 and the light reduction filter system 4 are welded During the process, it is coaxially set on the inner wall of the system shell 2 and transmits the image information of the weld seam during the welding process. The light reduction filter system 4 is driven by the motor transmission system during the non-welding process and realizes the guidance and calibration before welding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com