Controller of electrically controlled three-speed medium voltage motor and operation mode of controller

A technology of motor controller and operation mode, which is applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., and can solve the problems of low integration, complex structure, lack of tension adjustment, stepless control of emergency release, etc. , to achieve the effect of improving work efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

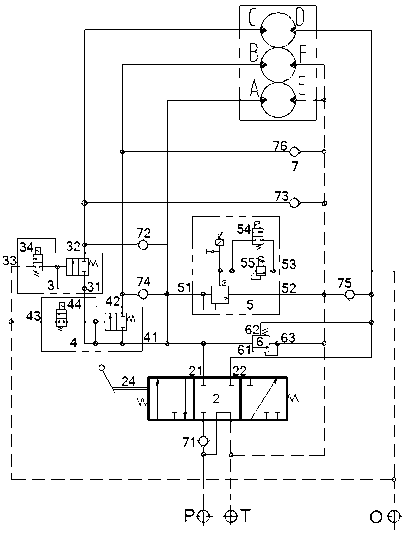

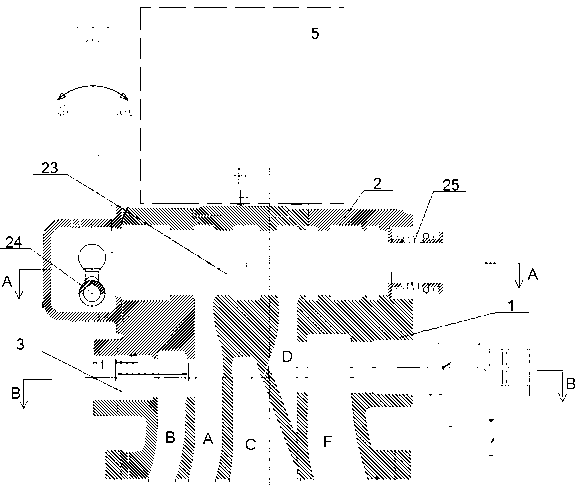

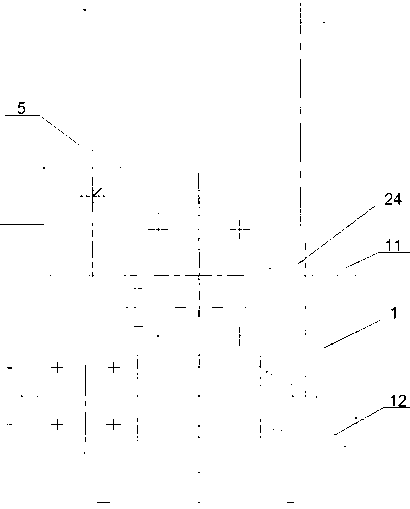

[0080] An electronically controlled three-speed medium-voltage motor controller, including a controller main body 1 and a main control valve 2, a high-speed switching valve 3, a low-speed switching valve 4, a safety tension valve 5, a balance valve 6 and a one-way valve 7 arranged inside the controller The high-speed switching valve 3 and the low-speed switching valve 4 are pilot control valves, the high-speed switching valve 3 includes a high-speed electromagnet 34, the low-speed switching valve 4 includes a low-speed electromagnet 44, and the safety tension valve 5 includes a safety electromagnet 54 and proportional electromagnet 55; the one-way valve 7 includes a one-way valve 71, a two-way valve 72, a three-way valve 73, a four-way valve 74, a fifth one-way valve 75 and a sixth one-way valve. One-way valve 76;

[0081] One side of the main control valve 2 communicates with the main oil inlet P and the main oil return port T provided on the controller body 1, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com