Connecting element, part assembly and method for forming the part assembly

A technology of components and parts, applied in the direction of connecting components, thin plate connections, mechanical equipment, etc., can solve the problems of deformation of riveted sections and inability to form riveted edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

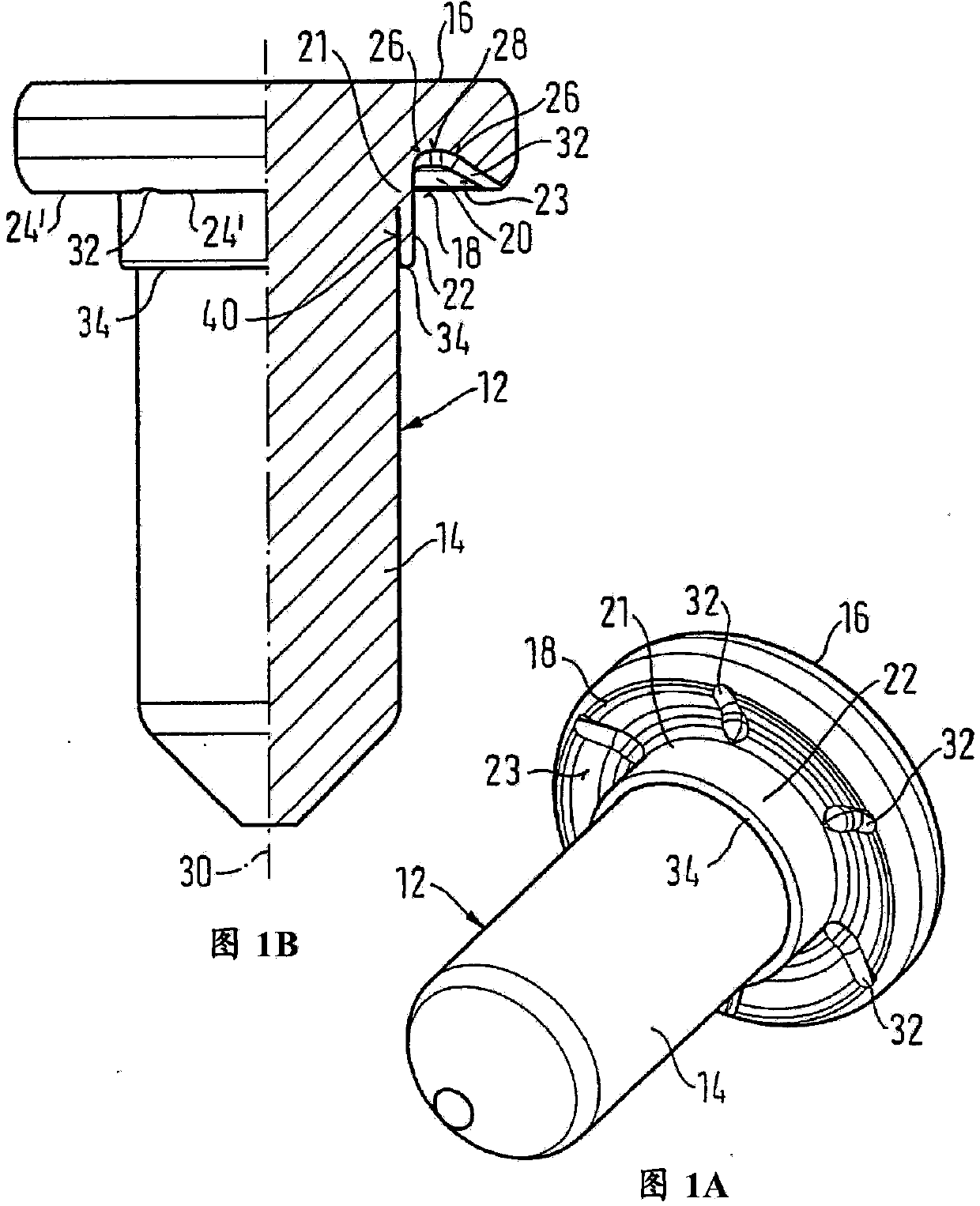

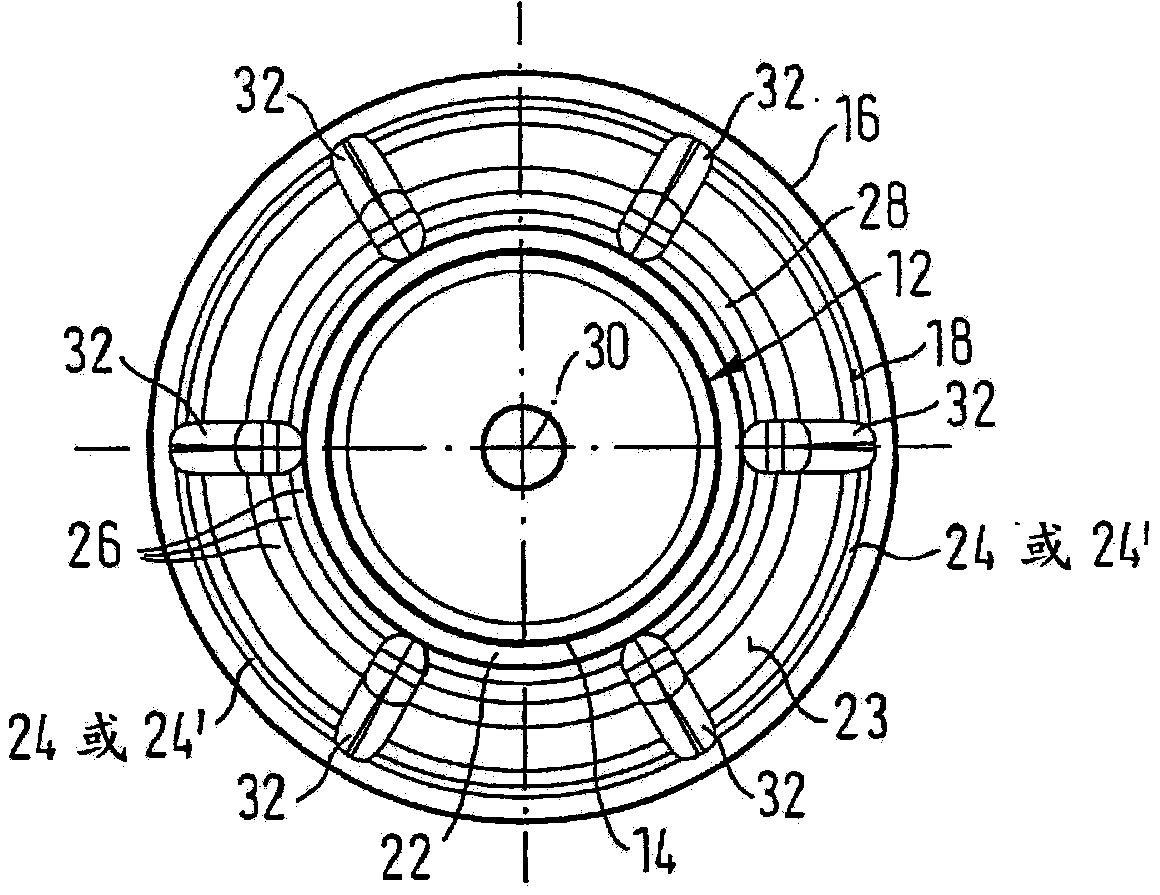

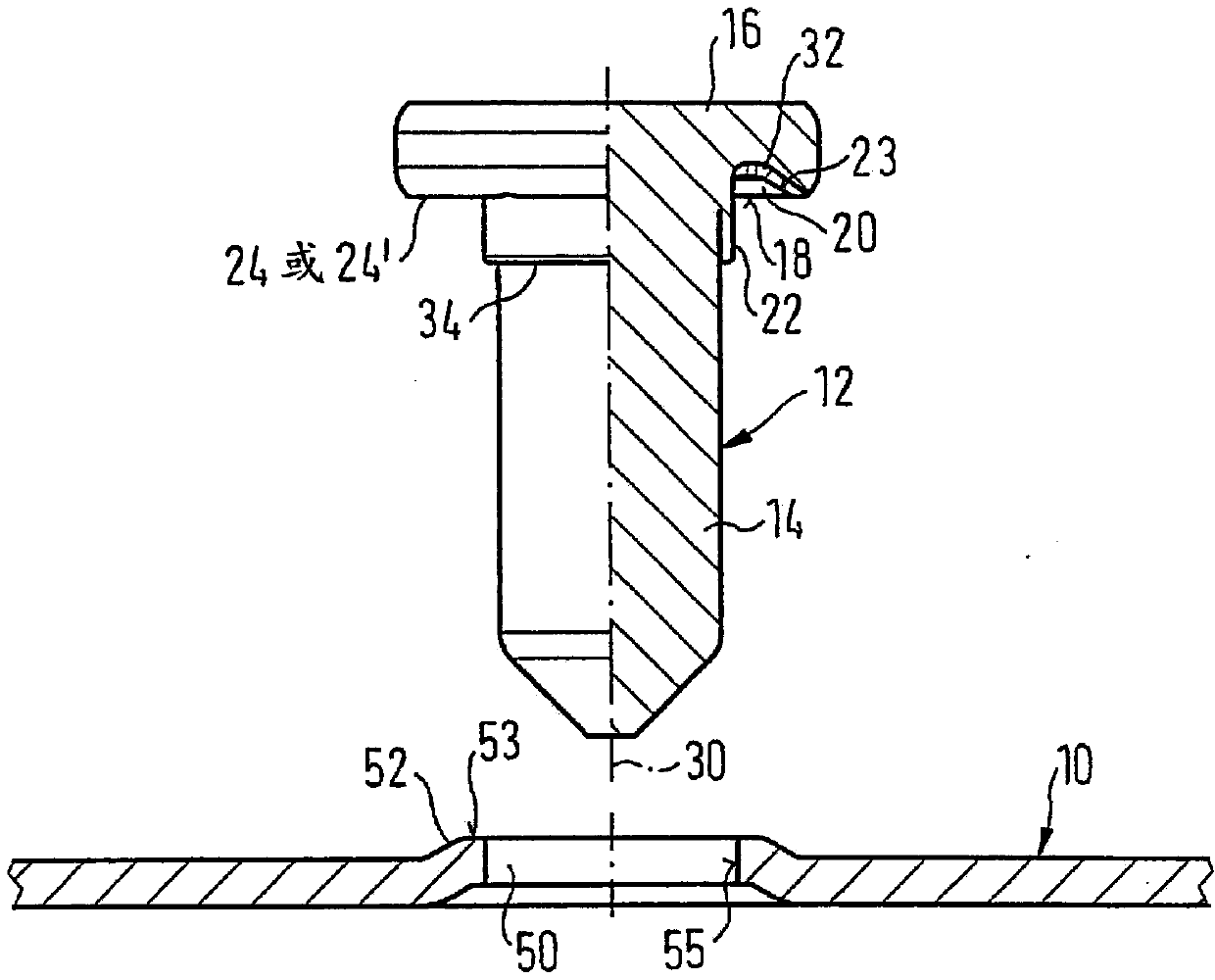

[0029] refer to Figures 1A-1C and Figure 2A-2B , shows the element 12 connected to the sheet metal part 10 by riveting. The element 12 is in the form of a centering element with a shank 14 and a head 16, wherein the head has on its side 18 facing the sheet metal part 10 an at least approximately annular groove 20 radially inside Merges with cylindrical section 21 of head 16 , which in turn merges with shank 14 and tubular riveting section 22 , which surrounds shank 14 in the region of head 16 , ie directly below head 16 . The annular groove 20 is located inside the annular contact surface 24, and the annular contact surface is located radially outside the annular groove, or is located radially outside the contact surface formed by the ring segment 24', and the annular groove 20 is located radially outside the annular groove. On the outside, the contact surface 24 or 24 ′ merges via an at least approximately conical wall 23 . The conical wall 23 may preferably have a cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com