Method for attaching a trim to a clock casing element and casing element manufactured according to said method

A technology for external components and clocks, applied to clocks, mechanically driven clocks, visually indicating time, etc., can solve problems such as hole clogging, holes not having clean edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

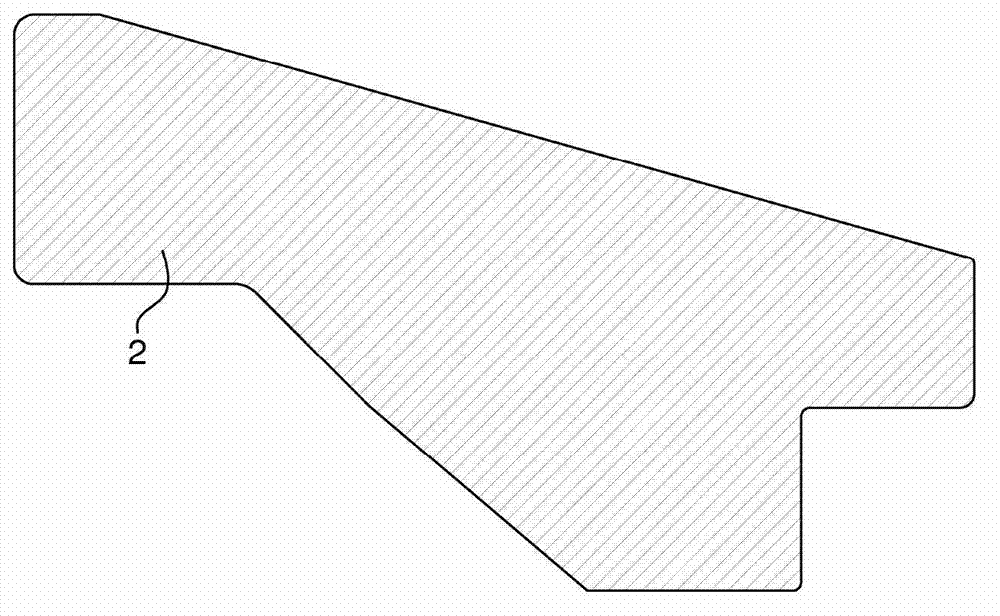

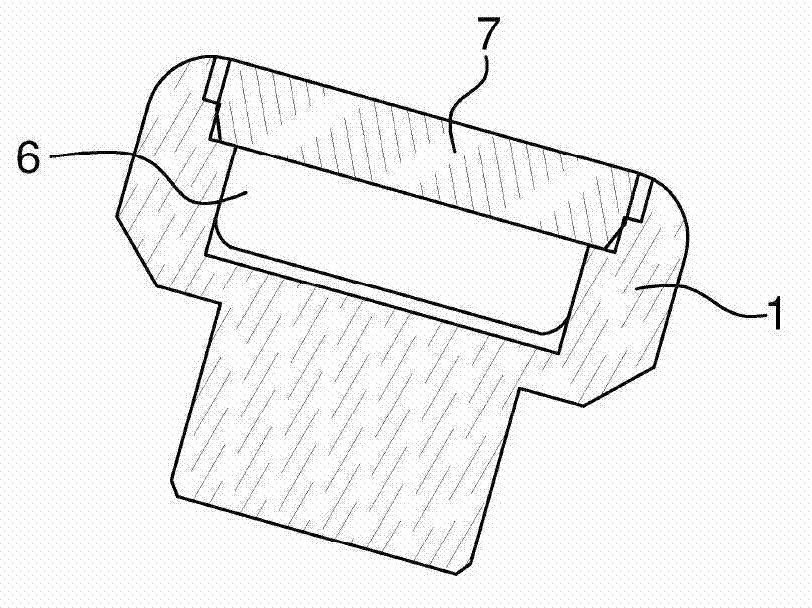

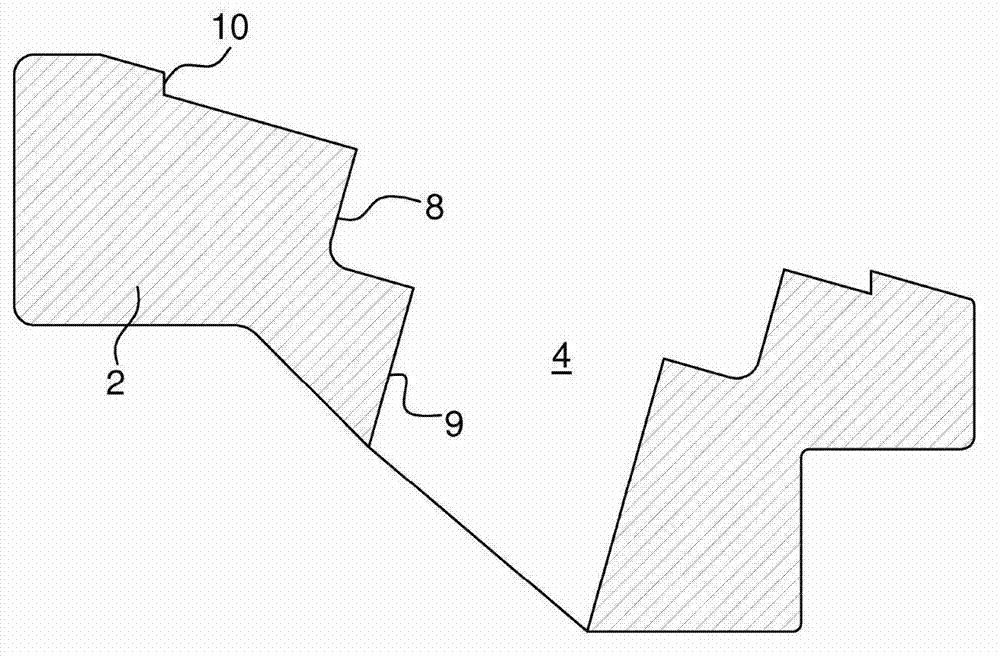

[0015] figure 1 The timepiece exterior element 2 is shown, which is called "base", into which the decoration will be integrated. More specifically, the element here is the bezel. figure 2 Decoration 1 is shown. It is a phosphor plate 6 arranged under the sapphire glass 7 carried by the decoration 1 . The phosphorescent sheet is called "luminova" (registered trademark). exist image 3 , substrate 2 is perforated on both sides. According to a variant, said holes may be blind holes. The perforations include a plurality of steps or shoulders. The stepped portions 8 and 9 are used to receive the phosphor sheet 1, and the stepped portion 10 is used to receive electrodeposits which will be described below.

[0016] Such as Figure 4 As shown, the mold part 5 is inserted into the perforated base 2 . The model parts are temporary inserts forming an essential part of the invention. It prevents later electrodeposition from penetrating into the holes 8, therefore, the mold part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com