Cloth rolling method for cloth drying machine

A technology of cloth drying machine and cloth rolling roller, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc. It can solve problems such as easy loosening, large volume, and affecting the effect of cloth rolling, and achieves convenient operation and simple structure , The effect of reducing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

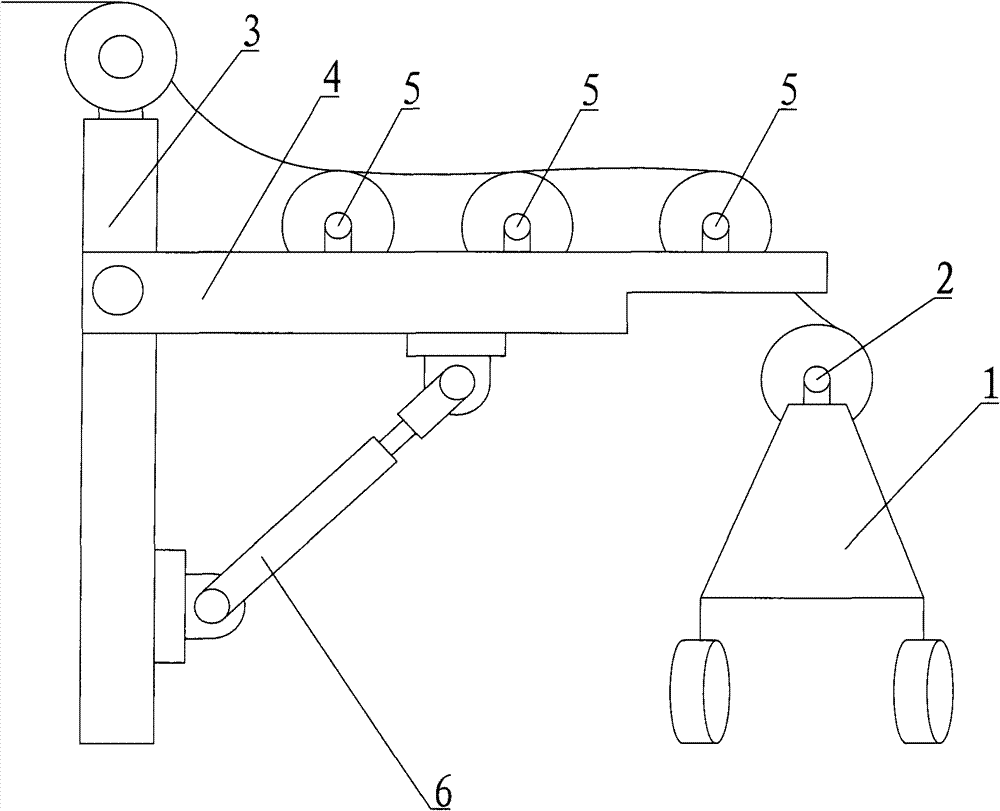

[0010] Such as figure 1 As shown, a cloth rolling method of a cloth drying machine in this embodiment, the cloth rolling device used in this method includes a cloth rolling roller 2 arranged on a movable frame 1, a cloth rolling roller 2 arranged on a frame 3 and driven The driving device, the support frame 4 that is rotatably connected with the frame 3, at least 3 conveying rollers 5 installed on the support frame 4, and the hydraulic cylinders 6 that support the support frame 4 on the frame 3 on both sides, the method is as follows : (a), the dried cloth is passed through the conveying roller, and arrives at the cloth roll for coiling; (b), adjusts according to the thickness of the cloth coiled on the surface of the cloth roll in step (a), when the volume of the coiled cloth When the thickness is getting thicker and thicker, adjust the upward lifting of the support frame through the hydraulic cylinder, so that there is a certain distance between the cloth roll and the suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap