A junction box cover gasket for fixing a thermal switch

A thermal switch and junction box technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of not being easy to deform, not being able to ensure the sealing performance well, and the gasket and the surface of the upper case cover are not well sealed, etc. To achieve the effect of ensuring the sealing of the installation and strong resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

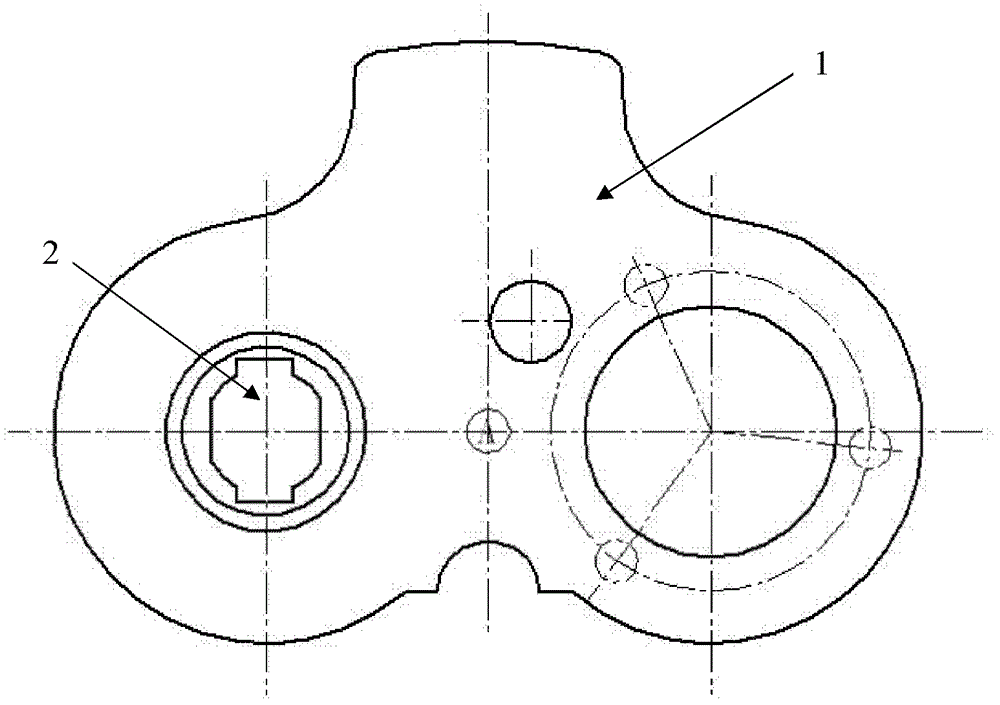

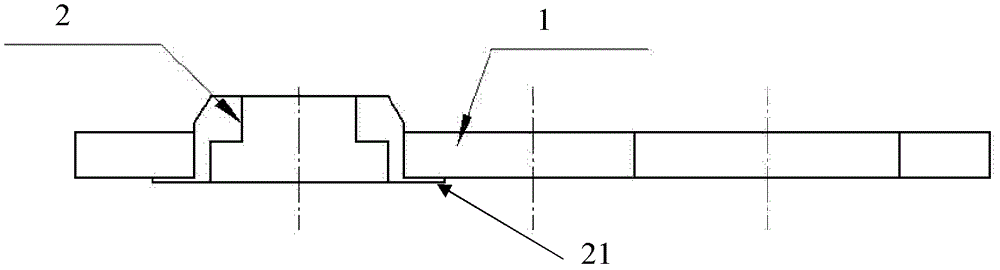

[0015] Such as Figure 1~2 As shown, a junction box cover gasket for fixing a thermal switch, the shape of the gasket matches the junction box cover and the contact part of the upper casing cover of the compressor, and the gasket is composed of a foaming part 1 and a compact part 2, the shape of the foaming part 1 matches the junction box cover and the contact part of the upper casing cover of the compressor, and is made of PE foam material, which has good elasticity. After the junction box cover is installed and pressed The tightness has a better effect. The foaming part 1 is provided with a mounting hole, and the compact part 2 is arranged in the mounting hole. The compact part 2 is in the shape of a boss, and its bottom is provided with a skirt 21. The upper surface of the skirt 21 is in contact with the The foaming part 1 is bonded, so that the advantages of the original two materials are combined. The dense part is formed by one-time stamping of the dense material EPDM, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com