Tina multi-nozzle tip hot runner system

A technology of hot runner and runner, which is applied in the field of hot runner system of Tinado nozzle tip, which can solve the problems of lower processing requirements of customers' injection molds, easy to leak glue assembly and disassembly, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further description of the side-feeding glue hot runner system of the present invention in conjunction with the accompanying drawings.

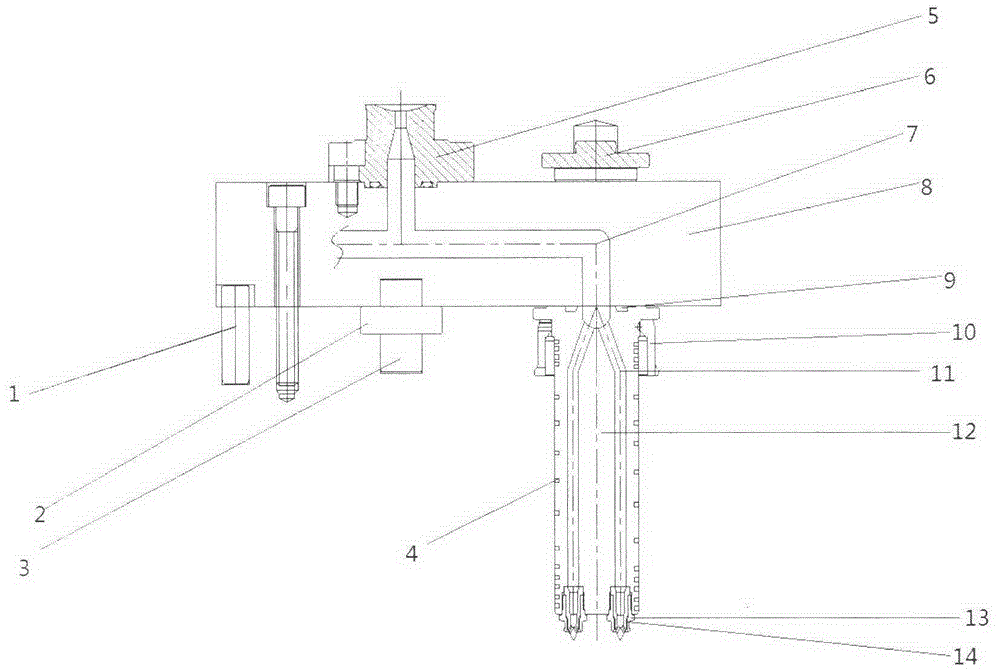

[0022] Such as figure 1 As shown, the tip hot runner system of Tina multi nozzle, said system includes splitter plate 8, main nozzle 5, sliding gasket 6, center gasket 2, center pin 3, anti-rotation pin 1, hot nozzle 12; The main nozzle 5 is arranged on the upper part of the manifold 8, and the plastic material enters the manifold 8 through the main nozzle 5 from the injection molding machine, and the center pin 3 is provided at the lower part of the manifold 8 corresponding to the main nozzle 5, The center gasket 2 is set between the central pin 3 and the splitter plate 8; the sliding gasket 6 is set on the upper part of the splitter plate 8, and the hot nozzle 12 is provided at the lower part of the splitter plate 8, One end of the hot nozzle 12 is connected to the splitter plate 8 through an integrated flange 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com