Bamboo floor board

A bamboo flooring and bamboo sheet technology, applied in the field of bamboo flooring, can solve the problems of affecting the service life of bamboo flooring, poor sound insulation and mute effect, easy cracks, warping, etc., and achieves enhanced foot comfort, convenient disassembly and assembly, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

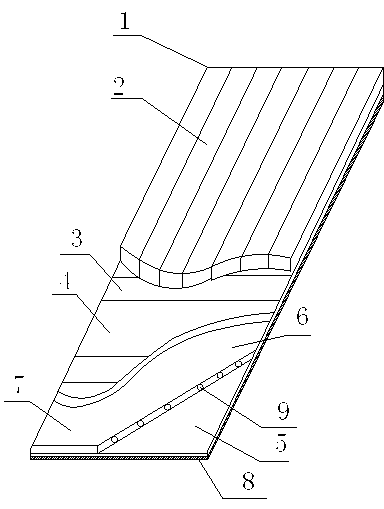

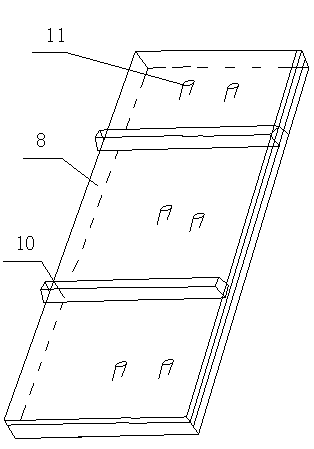

[0012] like figure 1 and 2 Shown, a kind of bamboo floor of the present invention, upper surface 1 is formed by vertical tile of many slices of bamboo slices 2, and the lower surface of bamboo slices 2 is attached with many transverse viscose strips 3, and the lower surface of viscose strips 3 It is the gauze layer 4, the gauze layer 4, the bamboo slices 2, and the viscose strips 3 are bonded by an adhesive, and the lower surface of the gauze layer 4 is also provided with a composite layer 7 of a rubber layer 5 and a non-woven fabric 6, and the composite layer 7 and the gauze layer 4 are bonded by an adhesive, the lower surface of the composite layer 7 is provided with a layer of mute film 8, the composite layer 7 is provided with longitudinally extending ventilation holes 9, and the back side of the composite layer 7 is provided with ground ribs 10, quiet A rubber pad 11 is pasted on the membrane 8 . A kind of bamboo floor of the present invention is provided with a layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com