Simulation test method and system for heavy oil delivery screw pump

A conveying screw and simulation test technology, applied in the computer field, can solve problems such as high experimental operation costs, difficulty in establishing a screw pump performance test system, and expensive construction of experimental equipment, and achieve the effect of solving the unrealizable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

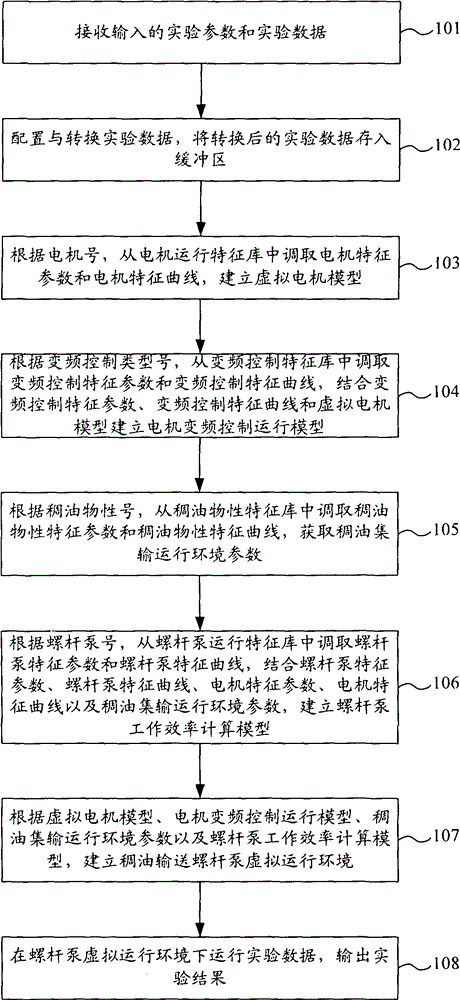

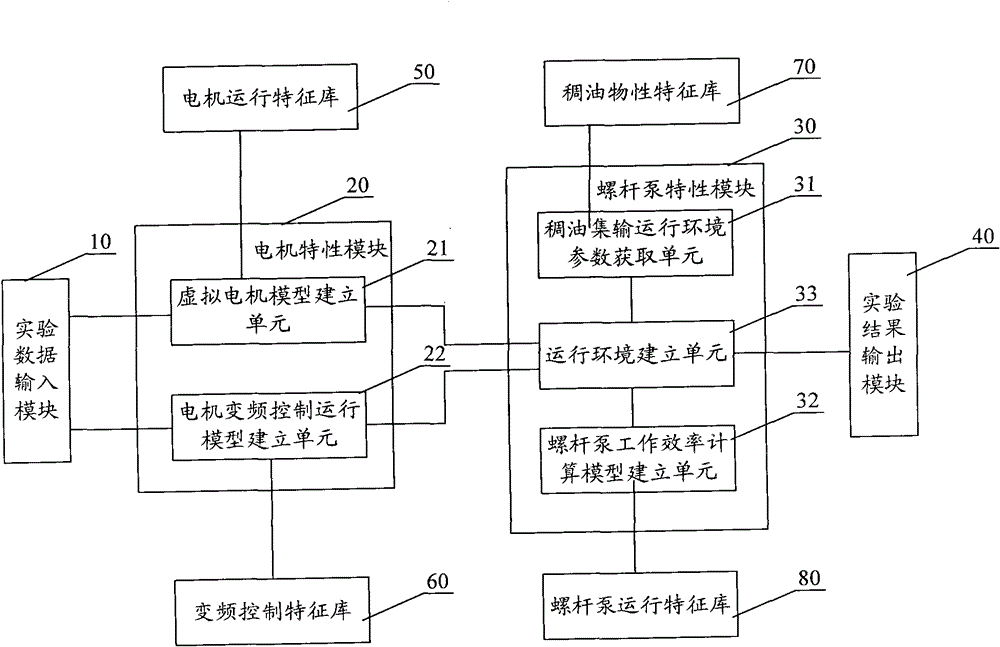

[0050] Aiming at the deficiencies in the technology and operation of the screw pump experimental device in the prior art, the present invention provides a heavy oil delivery screw pump simulation test method and system that is simple in application, wide in application range, convenient in operation, safe and reliable, and more energy-saving than conventional experimental methods. The method and the system adopt computer software technology, and can implement a comprehensive comprehensive test on the delivery characteristics of the heavy oil delivery screw pump. The core idea of the present invention is: firstly receive the input experimental parameters and experimental data, the experimental parameters include experimental type number, motor number, frequency conversion control type number, heavy oil physical property number and screw pump number; according to the experimental parameters, establish The virtual motor model and the motor frequency conversion control operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com