Modularized vibrating screen

A vibrating screen, modular technology, applied in the fields of filter screen, chemical instrument and method, solid separation, etc., can solve the problems such as difficulty in transporting the screen to industrial site, difficult transportation of large vibrating screen, high transportation cost, etc. Reduced difficulty, improved shock absorption, and easy upscaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

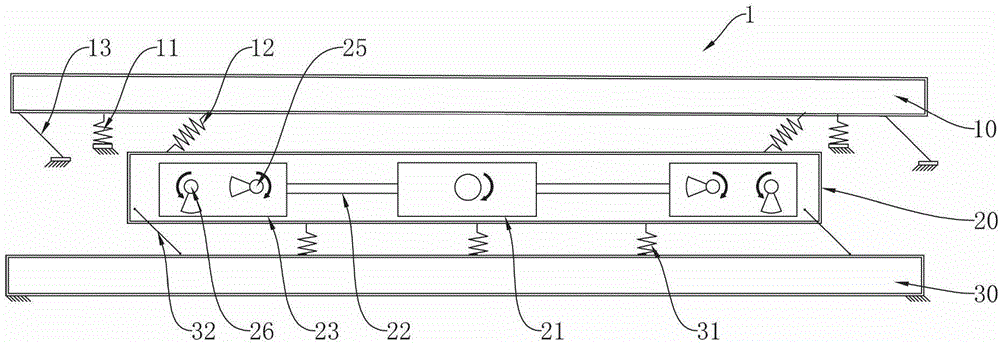

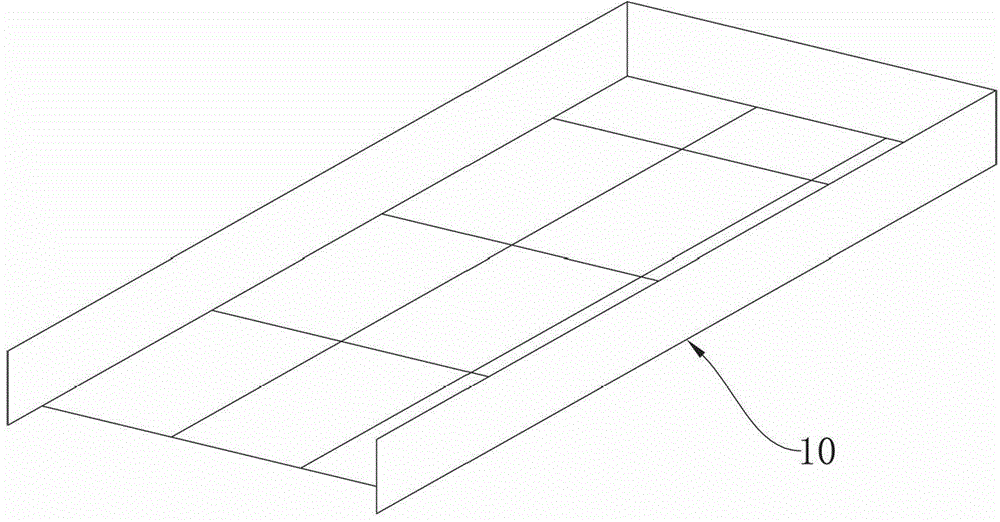

[0034] see Figure 1 to Figure 11 . The modular vibrating screen described in this embodiment includes a power input device, that is, a motor 2, and three unit modules 1, such as figure 1 shown. Each unit module 1 comprises a frame 30, a power layer 20 is installed above the frame 30, and a working layer 10, i.e. a screen box, is installed above the power layer 20, such as figure 2 shown. Power is transmitted between the working layer 10 and the power layer 20 through the spring device 12 , and the power transmission direction is the direction in which the spring device 12 expands and contracts. The upper end of the spring device 12 is fixedly connected with the working layer, and the lower end is fixedly connected with the power layer. The preferred angle between the spring device 12 and the power layer 20 is 45°. The working layer 10 is also connected to the ground through the first leaf spring 13 and connected to the ground through the damping spring 11 . Figure 9 A...

Embodiment 2

[0042] Different from Embodiment 1, the structure of the power layer 20 in this embodiment is a cross-shaped frame, such as Figure 12 shown. Correspondingly, the eccentric device can choose to use eccentric block or eccentric wheel. Figure 12 A form of installation of the eccentric device is shown, that is, the first eccentric mass 25' and the second eccentric mass 26' are directly fastened on the output shaft of the second reversing box 23. During installation, the angle between the two eccentric blocks needs to be set, preferably 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com