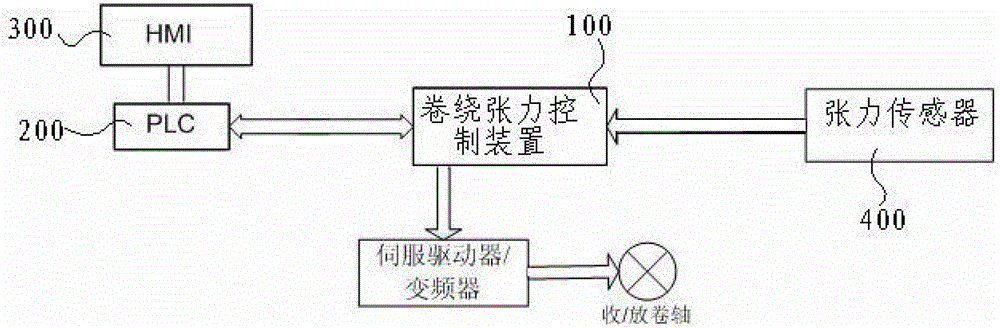

Winding tension control system

A technology of winding tension and control system, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems such as efficiency and accuracy cannot meet the requirements of high quality process, and achieve rich functions and flexible combination use , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

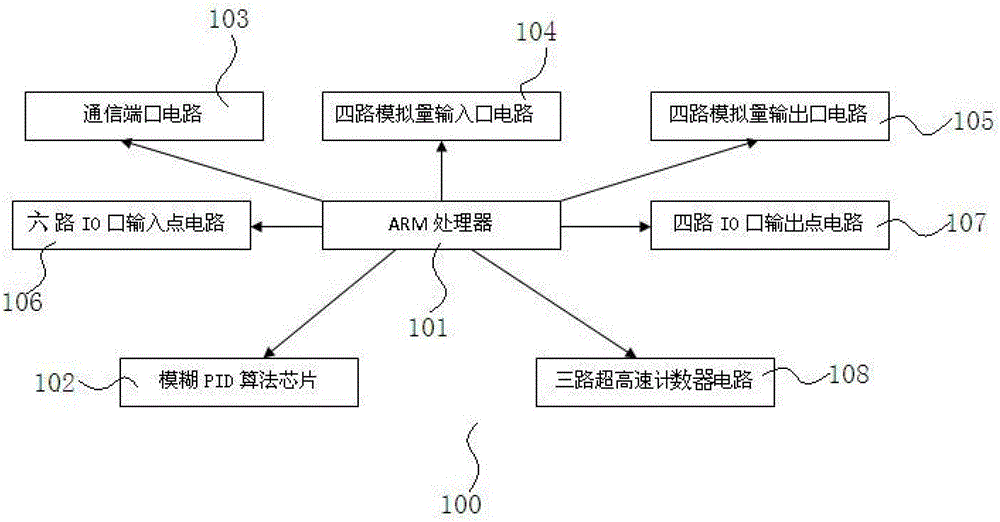

[0033] Based on the foregoing scheme, specific embodiments of the present invention are as follows:

example 1

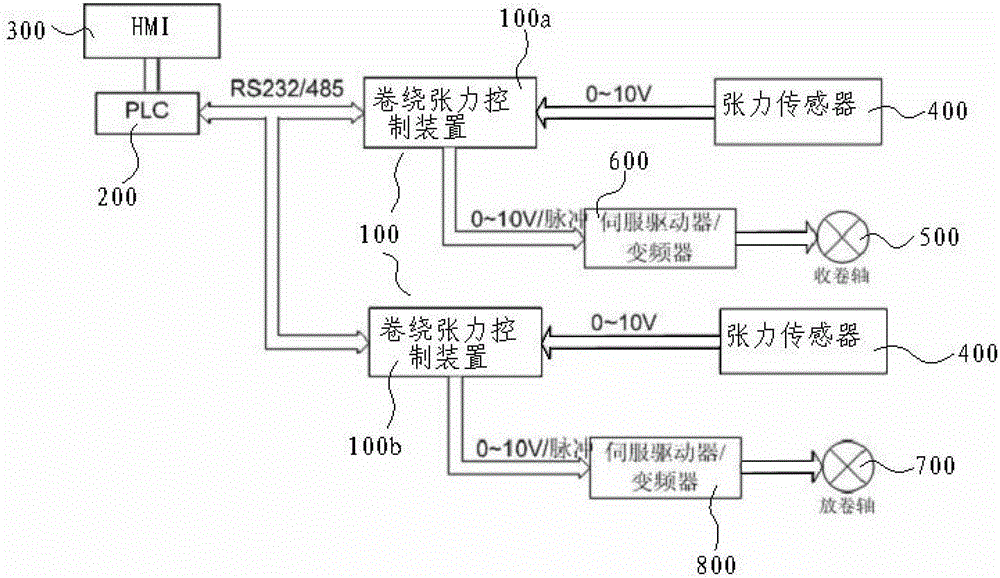

[0035] see figure 2 , as can be seen from the figure, this example is a solution for motor control using the above-mentioned system. In this example, the entire control system consists of a PLC (200), HMI (300), two winding tension control devices (100) and two tension sensors (400).

[0036] In terms of composition and structure, the PLC is connected to the HMI, as described above in detail, and will not be described in detail here. At the same time, the PLC communicates with the two winding tension control devices 100 through the RS232 / 485 communication interface. Among the two winding tension control devices 100 , the first winding tension control device 100 a is connected to the servo driver 600 driving the take-up shaft 500 and the second winding tension control device 100 b is connected to the servo driver 800 driving the unwinding shaft 700 . The two tension sensors 400 are respectively used to detect the tension value at the end of the winding shaft 500 and the tens...

Embodiment 2

[0099] This example is a solution for magnetic particle control using the above system. In this example, the entire control system is composed of PLC, HMI, winding tension control device, tension sensor, magnetic powder amplifier and magnetic powder clutch.

[0100] Among them, the PLC is connected with the HMI, and communicates with the winding tension control device. The winding tension control device is connected with the tension sensor, and connected with the magnetic powder clutch through the magnetic powder amplifier. The magnetic powder clutch is connected to the winding shaft and the unwinding shaft.

[0101] The operating principle of each component in this example is the same as that in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com