Inclined sliding groove rail pair with self-locking flat surface

A technology of inclined chute and inclined sliding rail, applied in the field of groove rail auxiliary device, can solve the problems of low efficiency of unlocking and resetting and locking of inclined core block, increased mold maintenance cost, complicated mold structure, etc., so as to improve the efficiency , simplify the structure, overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

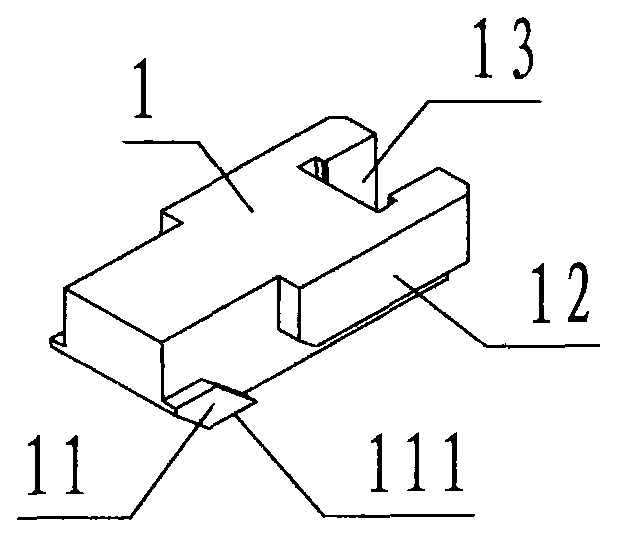

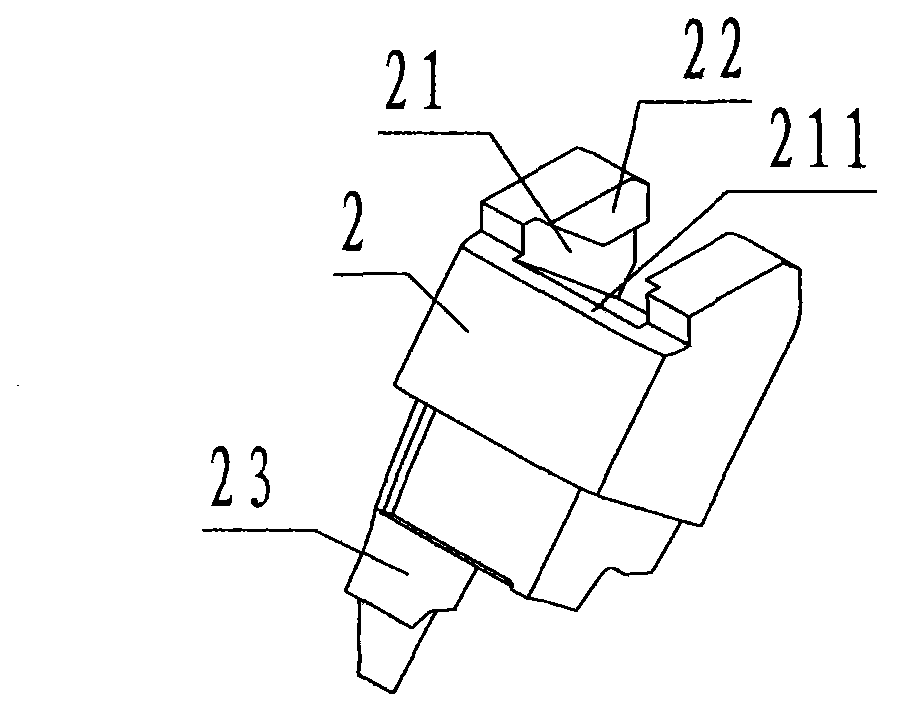

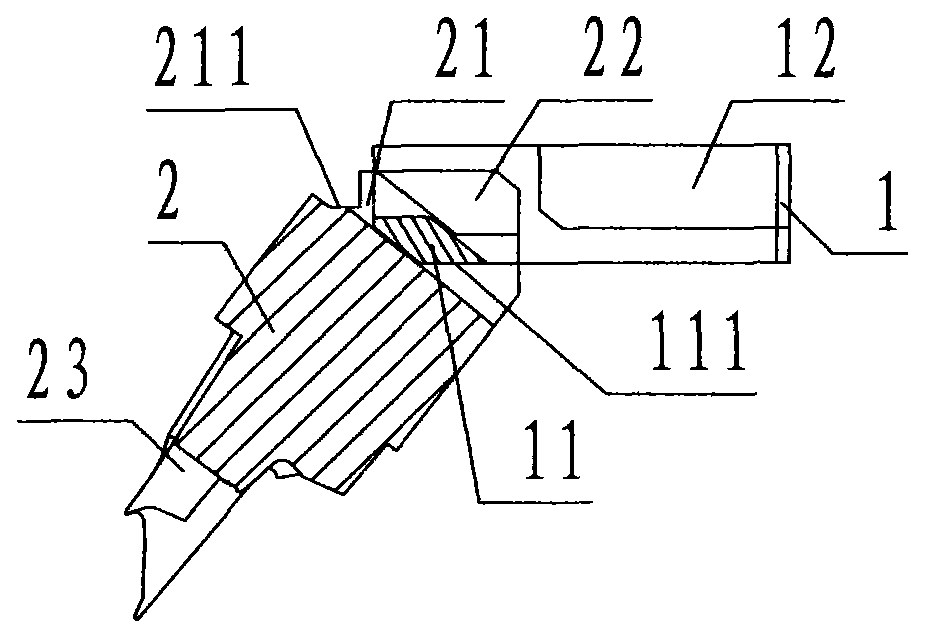

[0025] refer to Figure 1 to Figure 7 , a slanted rail pair with a self-locking plane of the present invention, including a driving slider 1 and a driven slider 2, wherein: the driving slider 1 is a rectangular block-shaped steel member, and the driving slider The front and rear sides of the block 1 are symmetrically provided with protruding inclined slide rails 11 and guide shoulders 12, wherein the front view projection of the inclined slide rails 11 is a parallelogram whose hypotenuse slopes downward from left to right, and the inclined slide rails 11 are located on the active The bottom of the front and rear sides of the left part of the slider 1, the lower left side of the active slider 1 is provided with an inclined surface that is flush with the left inclined surface of the inclined slide rail 11, and the bottom of the inclined slide rail 11 is called the collision plane 111; the guide shoulder 12 The front view projection is rectangular, the guide shoulder 12 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com