Paper carrier bag

A handbag, paper-based technology, applied in the field of packaging, can solve the problem of glue or paste or adhesive sticking and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

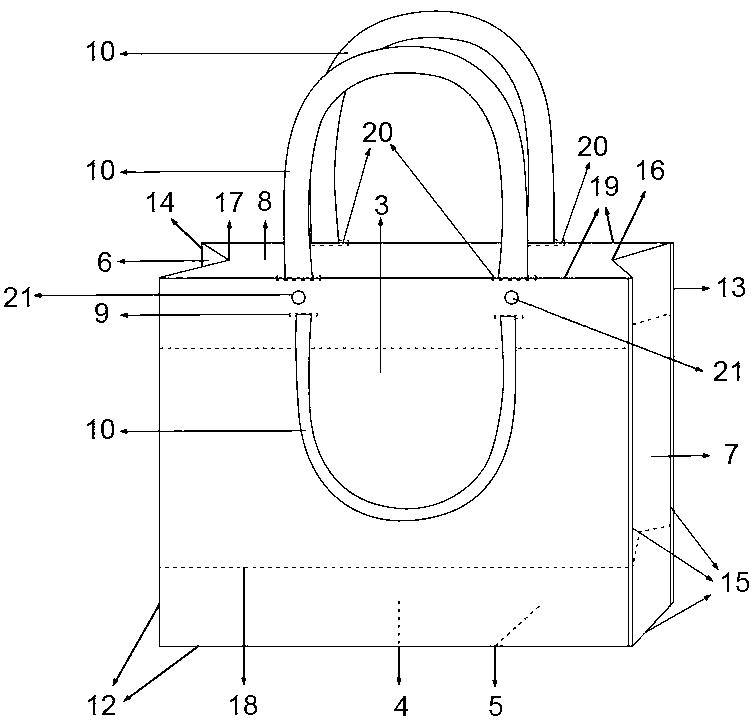

[0025] Such as figure 1 As shown in the figure, a paper handbag is formed by folding and folding, and the structure of the bag is controlled by the handle.

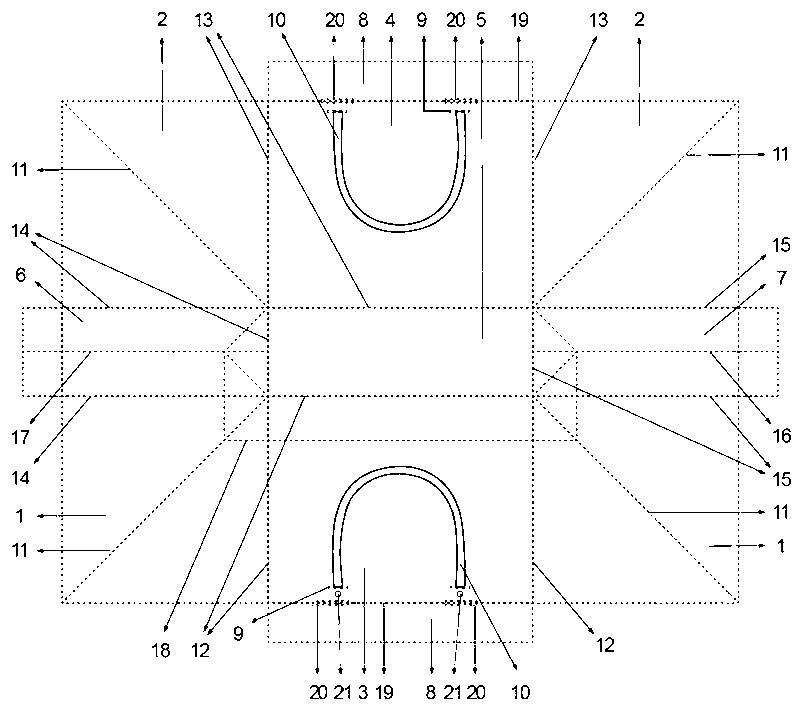

[0026] Such as figure 2 Shown is a schematic diagram of a paper tote bag embodiment unfolding the bag body.

[0027] Such as figure 2 Shown, a kind of paper handbag embodiment mark intention.

[0028] Such as figure 2 As shown, the paper handbag must be formed and crimped before being folded and formed, as marked: 11, 12, 13, 14, 15, 16, 17 and other crimping work.

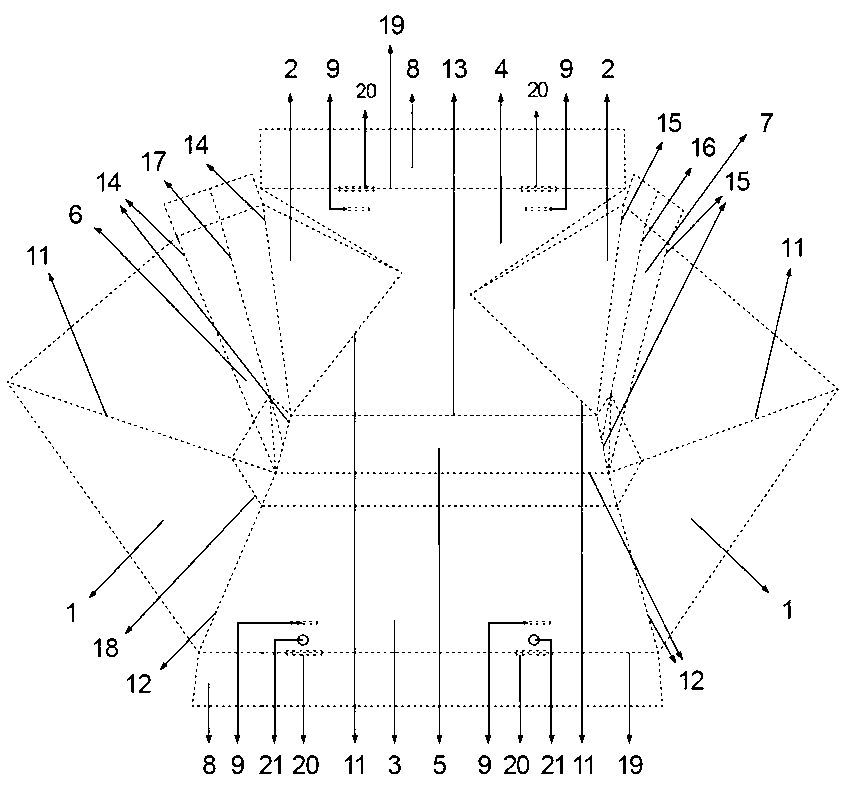

[0029] Such as image 3 As shown, a schematic diagram of a specific implementation of the folding example.

[0030] Such as image 3 As shown, first fold from the diagonal crimping line 11, the part 1 that is folded in from the back of the bag toward the inside of the bag, the part 2 that is folded in from the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com