Small dripping pipe

A dripping and tube wall technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as low efficiency of evaporators and absorbers, uneven dripping, and reduced work efficiency , to achieve the effects of low equipment utilization, efficiency improvement, and efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

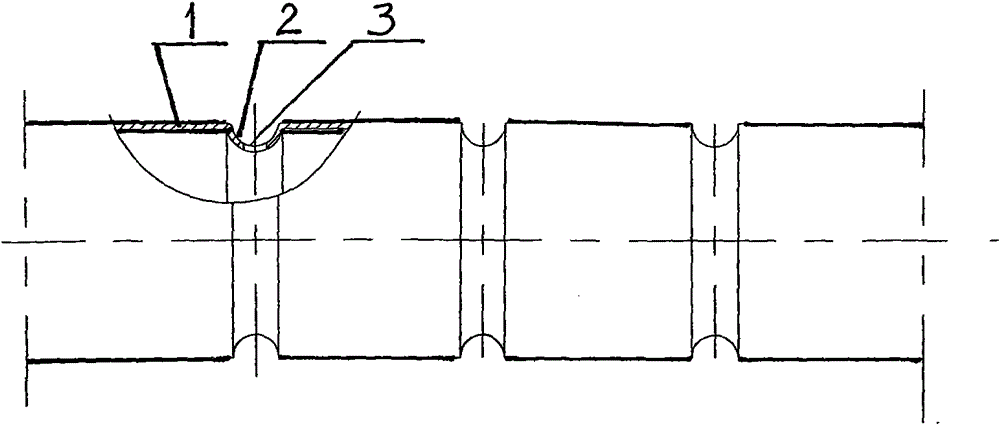

[0016] see figure 1 , the dripping small tube 1 of the present embodiment 1, its structure is: the tube wall is evenly and equidistantly processed with a plurality of annular diversion grooves 2, and the tube wall in the diversion groove 2 is drilled with small holes 3 communicating with the inside of the tube, And the aperture 3 in the diversion groove is drilled on the top of the dripping tubule.

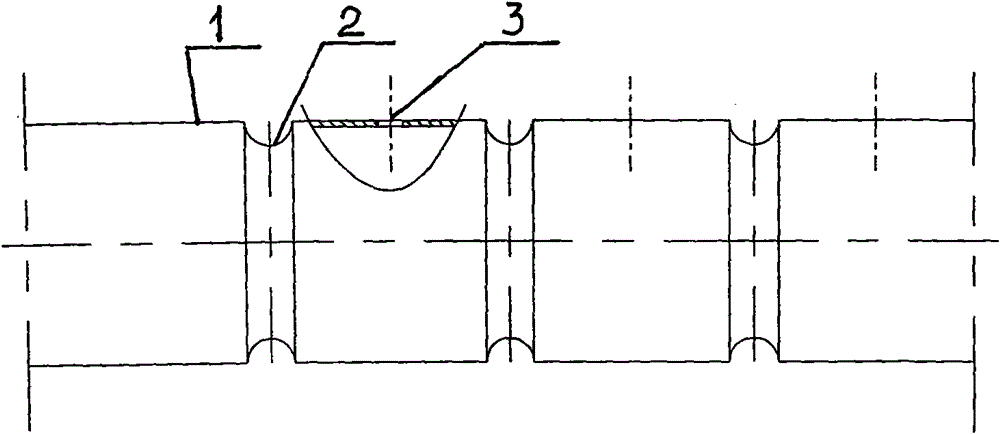

[0017] see figure 2 , the dripping small tube 1 of the present embodiment 2, its structure is: the tube wall is uniformly and equidistantly processed with a plurality of annular diversion grooves 2, and the tube wall is drilled with small holes 3 communicating with the inside of the tube, but the small holes 3 are not drilled. In the diversion tank, small holes can be drilled on the top of the drip tube or other parts.

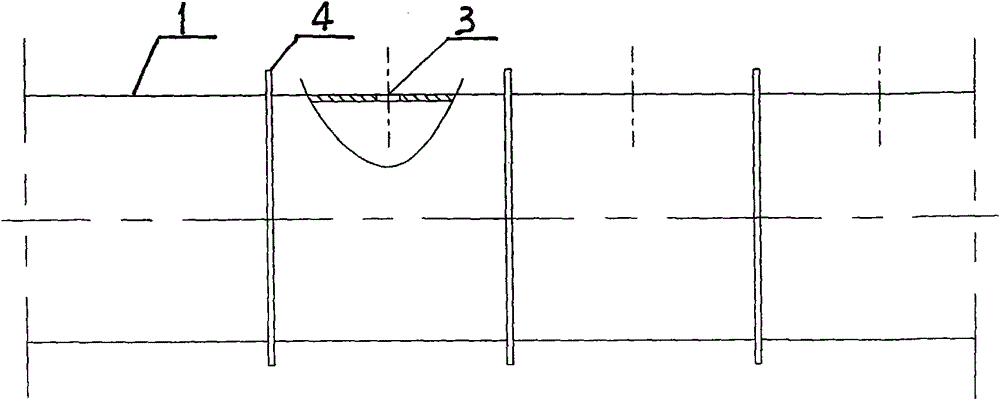

[0018] see image 3 , The small dripping tube 1 of the present embodiment 3 has a structure as follows: a plurality of annular baffles 4 are uniformly and equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com