Completion design method by bottom water reservoir horizontal well segregated water control

A technology of bottom water reservoir and design method, which is applied in wellbore/well components, earthwork drilling, and fluid production, etc., can solve the problems of inability to meet the requirements of fast completion, a large variety of data, and difficulty in collection, and achieves long-term non- The effect of water recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

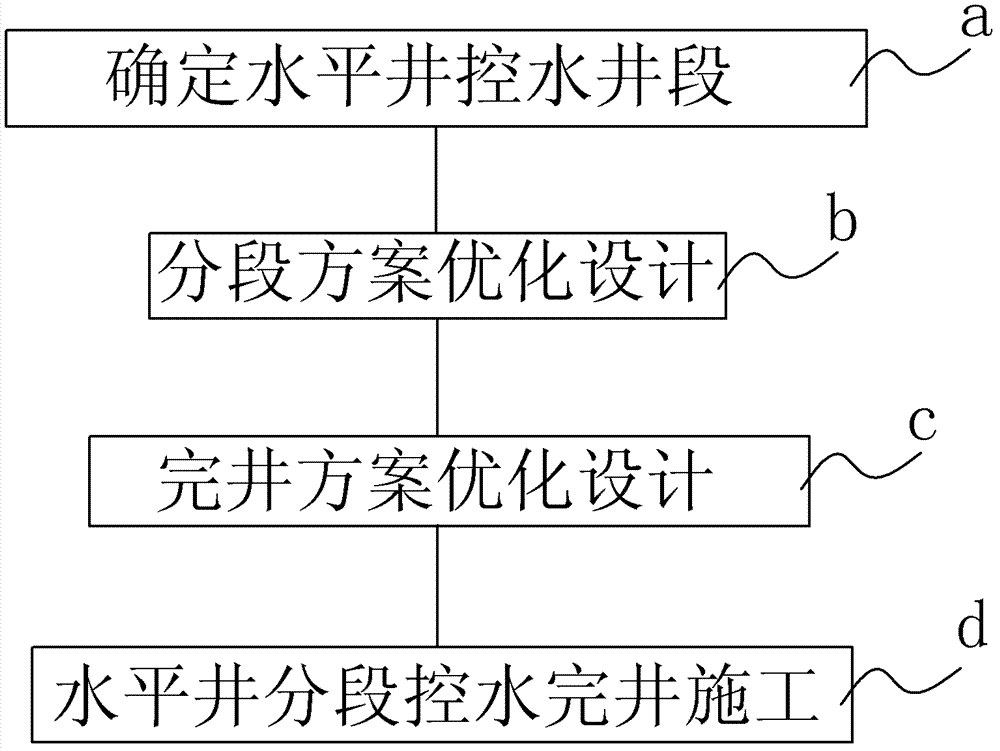

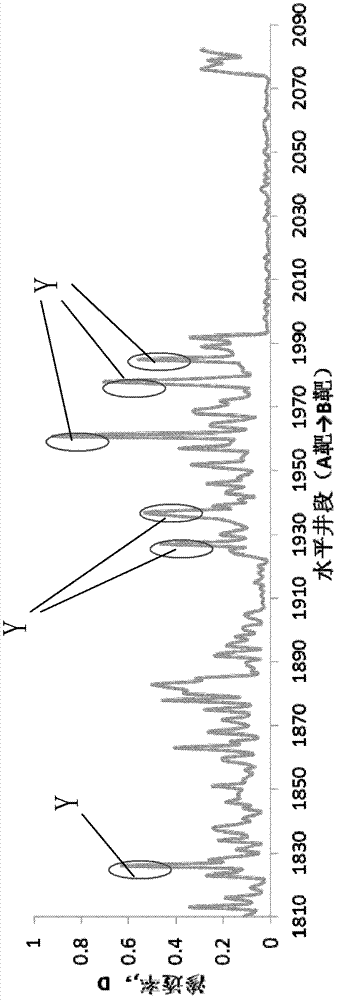

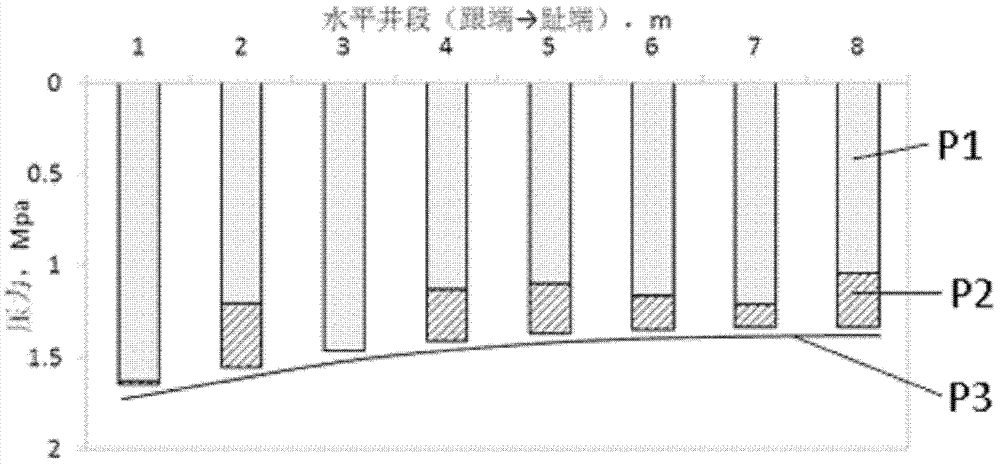

[0048] The method for designing the completion of horizontal wells in bottom water reservoirs with segmental water control according to the present invention mainly performs the construction design of well completion with segmental water control through segmental optimization design and optimization design of horizontal wells in bottom water reservoirs. This method first comprehensively analyzes the influencing factors of water-control completion of horizontal wells in bottom-water reservoirs, establishes the corresponding segmentation principles, and carries out the design of segmental optimization schemes; then, according to the established The relationship between water breakthrough time and production capacity of the well section, using the principle of consistent water breakthrough time and the minimum total additional see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com