Device for continuously producing alkyl-lithium lithium feeder

A lithium alkyl, continuous process technology, applied in the chemical industry, can solve problems such as affecting the quality of raw materials and production costs, achieve good sealing and meet the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

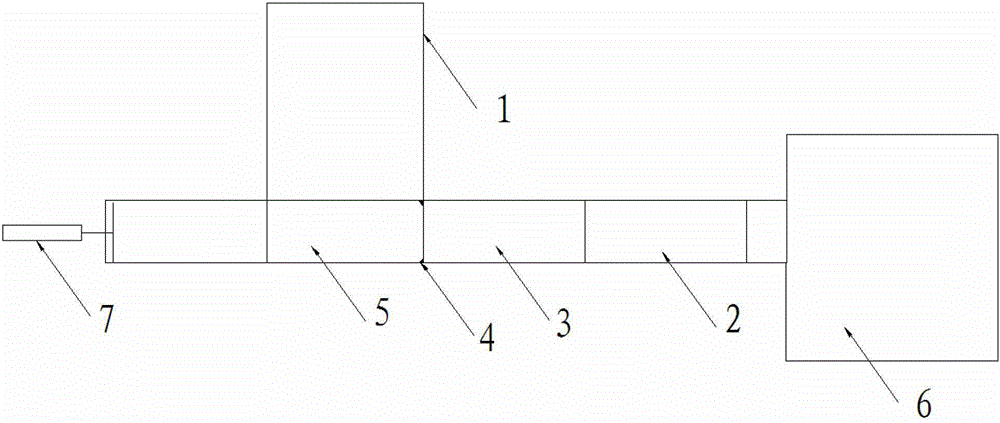

[0012] The present invention will be further described below in conjunction with accompanying drawing:

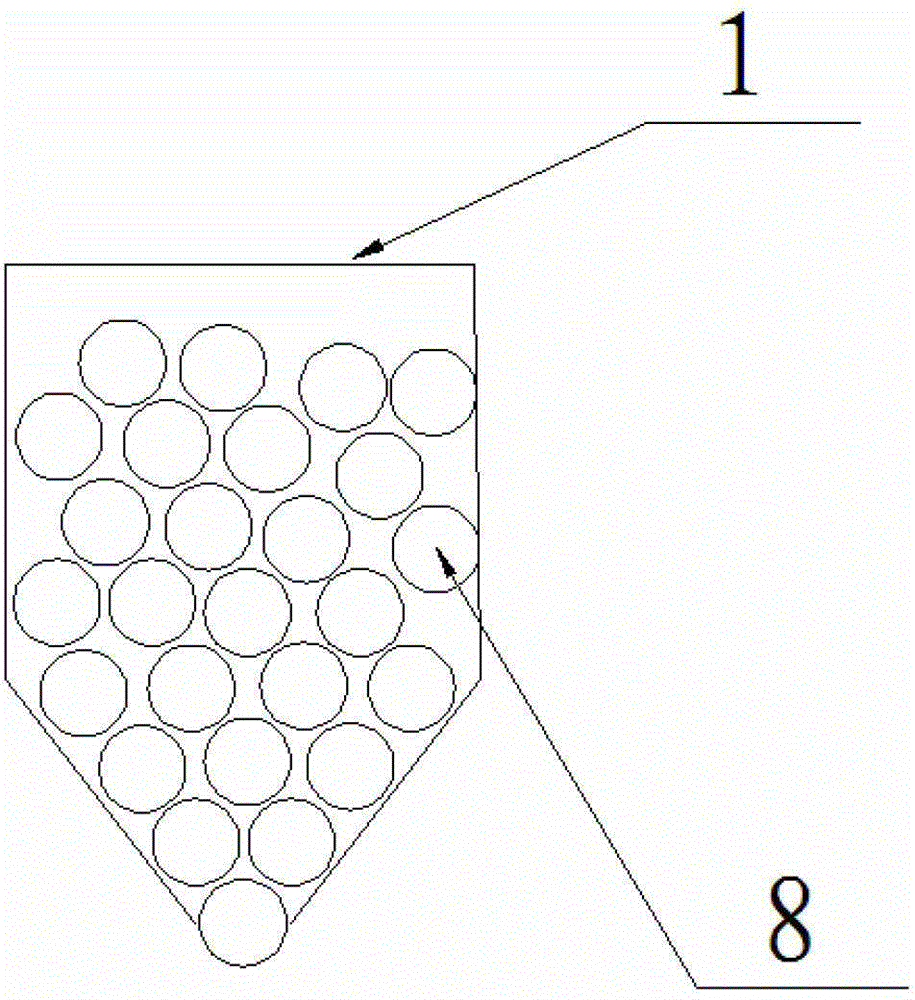

[0013] Such as figure 1 , figure 2 , a continuous production of alkyl lithium thrower device, including a hopper 1, a conveyor 5, a reactor 6 and a hydraulic propeller 7, the conveyor 5 is arranged below the hopper 1, and one end of the conveyor 5 is provided with a hydraulic propulsion 7, and the other end of the conveyor 5 is provided with a reactor 6. Lithium metal rods 8 are stored in the hopper 1.

[0014] The conveyor 5 is provided with a movable buckle 4 .

[0015] The continuous production of alkyllithium lithium feeder device of the present invention adopts a centralized gap to drop a certain amount of metal lithium columns to the lower conical hopper 1, and utilizes the self gravity of the lithium columns to slide into the pusher bed, when the frontmost lithium column 2 gradually When entering the reactor to a certain length, the lithium column 3 in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com