Crushing machine

A crushing machine and crushing technology, applied in the field of crushing machines, can solve the problems of fragile blades, single function, and non-adjustable crushing fineness, etc., and achieve the effect of convenient transmission and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

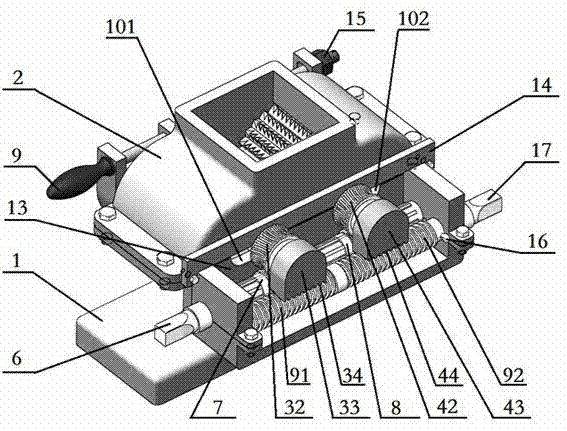

[0031] Such as figure 1 Shown, a kind of crushing machine, it comprises organic case 1 and has the casing cover 2 of feeding port; Also comprises base 13, the first crushing external gear 3, the second crushing external gear 4, driving shaft 6 , the first worm screw 7, the second worm screw 8, the motor, the first crushing internal gear 5, the second crushing internal gear 10, the hand lever 9, the first shift fork 11 and the second shift fork 12. The base 13 is disposed outside the case 1 and integrally formed with the case 1 .

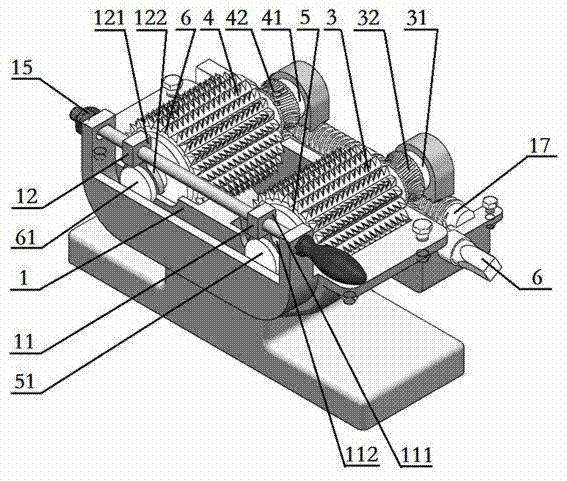

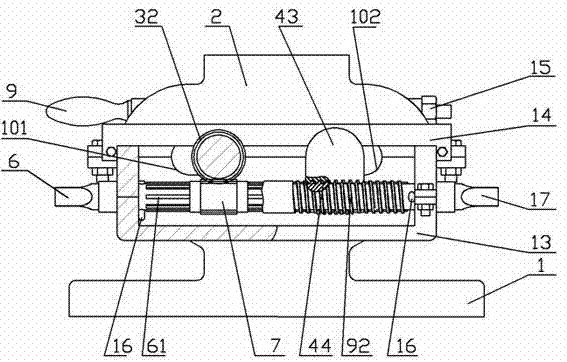

[0032] Such as figure 2 , 3 , and 4, the first crushing external gear 3 and the second crushing external gear 4 are horizontally arranged in the cabinet 1, and the cabinet 1 is horizontally provided with a first sliding groove 101 and a second sliding groove 102. The end of the first crushing external gear 3 is provided with a first transmission shaft 31, and the first transmission shaft 31 protrudes outside the casing 1 through the first sliding...

Embodiment 2

[0038] This example is except subordinate feature, and other is all identical with embodiment 1: pulverizes hardened soil clod, soil brick to recycle, pulverizes soil brick and does not need very strong teeth to grind and the effect of puncturing but needs the effect of extruding, can Rotate the two-stage screw rod 17 and adjust the distance between the crushing wheels so not so close. After the adjustment is completed, the double-stage screw rod 17 is locked, and the motor is driven to run the machine, and the soil block to be pulverized is dropped into from the feeding port on the casing cover 2 tops. After crushing, the fine particle product is output from the outlet below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com