Gear-selecting and shifting performance automatic testing device and method

An automatic test device and a technology for shifting gears, which are used in measuring devices, machine gear/transmission mechanism testing, vehicle testing, etc. Head connection and other problems, to achieve the effect of fast test response, reliable test data, and quick selection and shifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

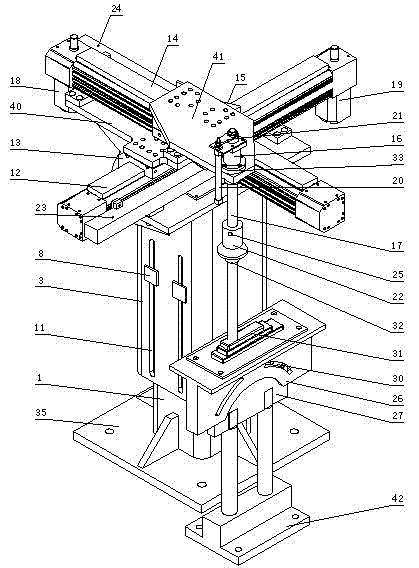

[0039] Such as figure 1 As shown, the automatic test device for gear selection and shift performance includes a lifting mechanism, a locking mechanism, a gear selection and shift actuator and a gear lever support.

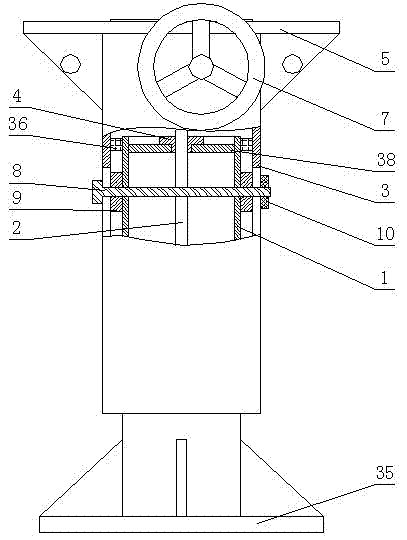

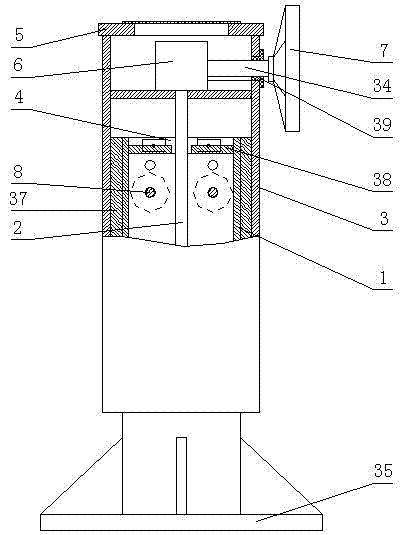

[0040] Among them, the structure of the lifting mechanism is as follows: figure 2 , 3As shown, the lifting mechanism includes an annular inner wall 1, a screw mandrel 2, an annular outer wall 3, a nut 4, a top cover plate 5, a worm gear mechanism 6, a handle 7 that drives the worm in the worm gear to rotate, a connecting rod 34 and a base 35. The annular inner wall 1 is fixed on the base 35, the annular outer wall 3 is sleeved on the annular inner wall 1 and is slidably matched with the annular inner wall 1, and a guide block 36 and a guide pad 37 are arranged between the annular outer wall 3 and the annular inner wall 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com