Aluminum alloy sheet superior in sintering coating hardenability

An aluminum alloy plate, sintering coating technology, applied in the field of Al-Mg-Si series aluminum alloy plate, to achieve the effect of high BH property

Inactive Publication Date: 2013-03-27

KOBE STEEL LTD

View PDF14 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0022] However, for the BH properties after room temperature aging in these conventional technologies, there is still room for improvement under the condition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Login to View More

Abstract

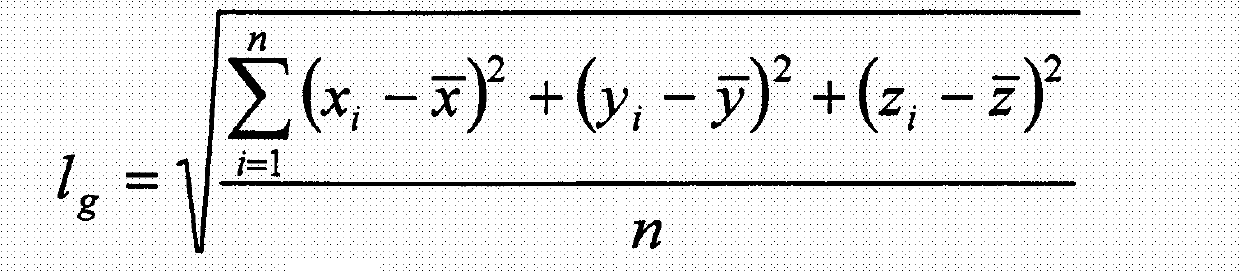

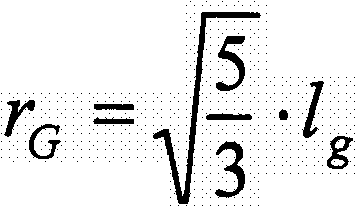

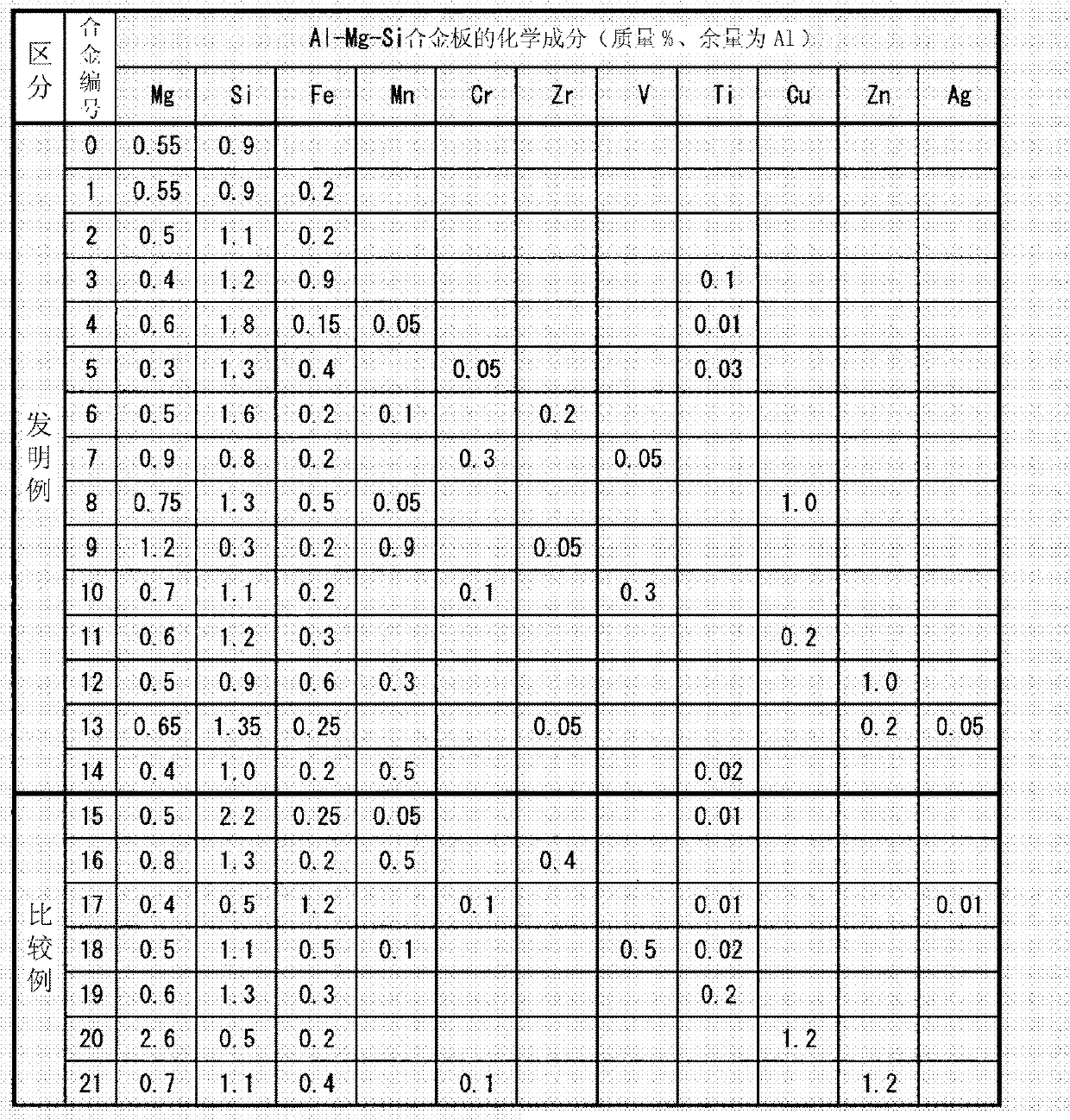

Provided is a 6000-series aluminum alloy sheet having the BH property under the low-temperature short-time condition after long-term room-temperature aging and the formability after long-term room-temperature aging. The specific 6000-series aluminum alloy sheet contains specific atom clusters which are detected by a three-dimensional atom probe field ion microscope and have great effect on the BH property, with a number density higher than a certain number density, thereby limiting the number of the small atom clusters, increasing the proportion of the large atom clusters and furthermore improving the BH property under the low-temperature short-time condition after long-term room-temperature aging.

Description

technical field [0001] The invention relates to an Al-Mg-Si series aluminum alloy plate. The aluminum alloy sheet referred to in the present invention is a rolled sheet such as a hot-rolled sheet or a cold-rolled sheet, and is an aluminum alloy sheet subjected to quenching and tempering such as solution treatment and quenching treatment, and before sintering, coating and hardening treatment. In addition, in the following description, aluminum is also called Al. Background technique [0002] In recent years, society has increasingly demanded weight reduction of vehicles such as automobiles in consideration of the global environment and the like. In order to respond to this demand, as materials for automotive panels, especially large body panels (outer panels, inner panels) such as hoods, doors, and roofs, in addition to steel materials such as steel sheets, excellent formability and sintering coating hardening properties, The use of lighter aluminum alloys is increasing. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/02C22C21/08

CPCC22C21/02C22C21/08C22C2200/00

Inventor 松本克史有贺康博宍户久郎

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com