Method for arranging nozzle holes of collector nozzle in airborne microorganism collection device and airborne microorganism collection device

A configuration method and a technology of nozzle holes, which are applied in sampling devices, measuring devices, biochemical cleaning devices, etc., can solve the problems of growth and the reduction of the capture efficiency of airborne planktonic bacteria, and achieve the effect of overcoming the reduction of capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Next, the method of arranging the nozzle hole of the trapping nozzle of the trapping device for airborne microbes of the present invention and an embodiment of the trapping device for microbes in the air will be described.

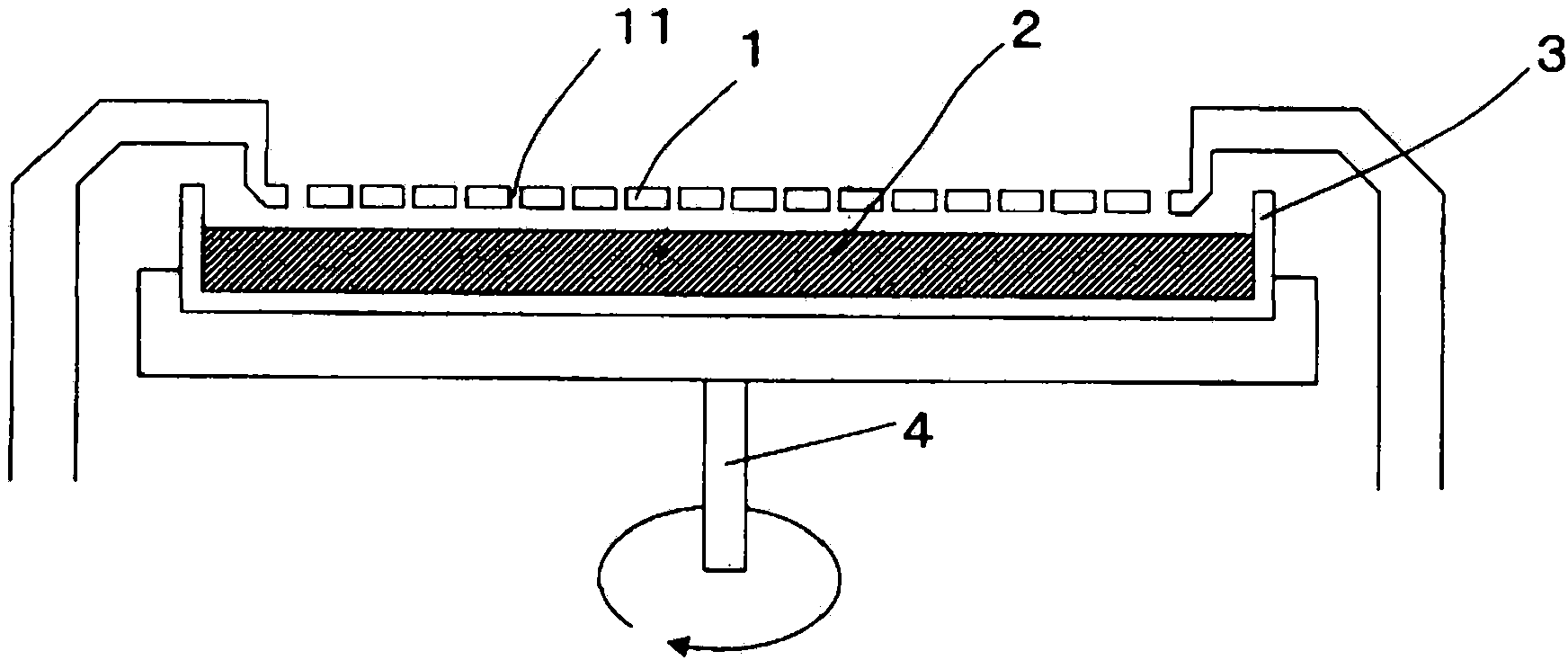

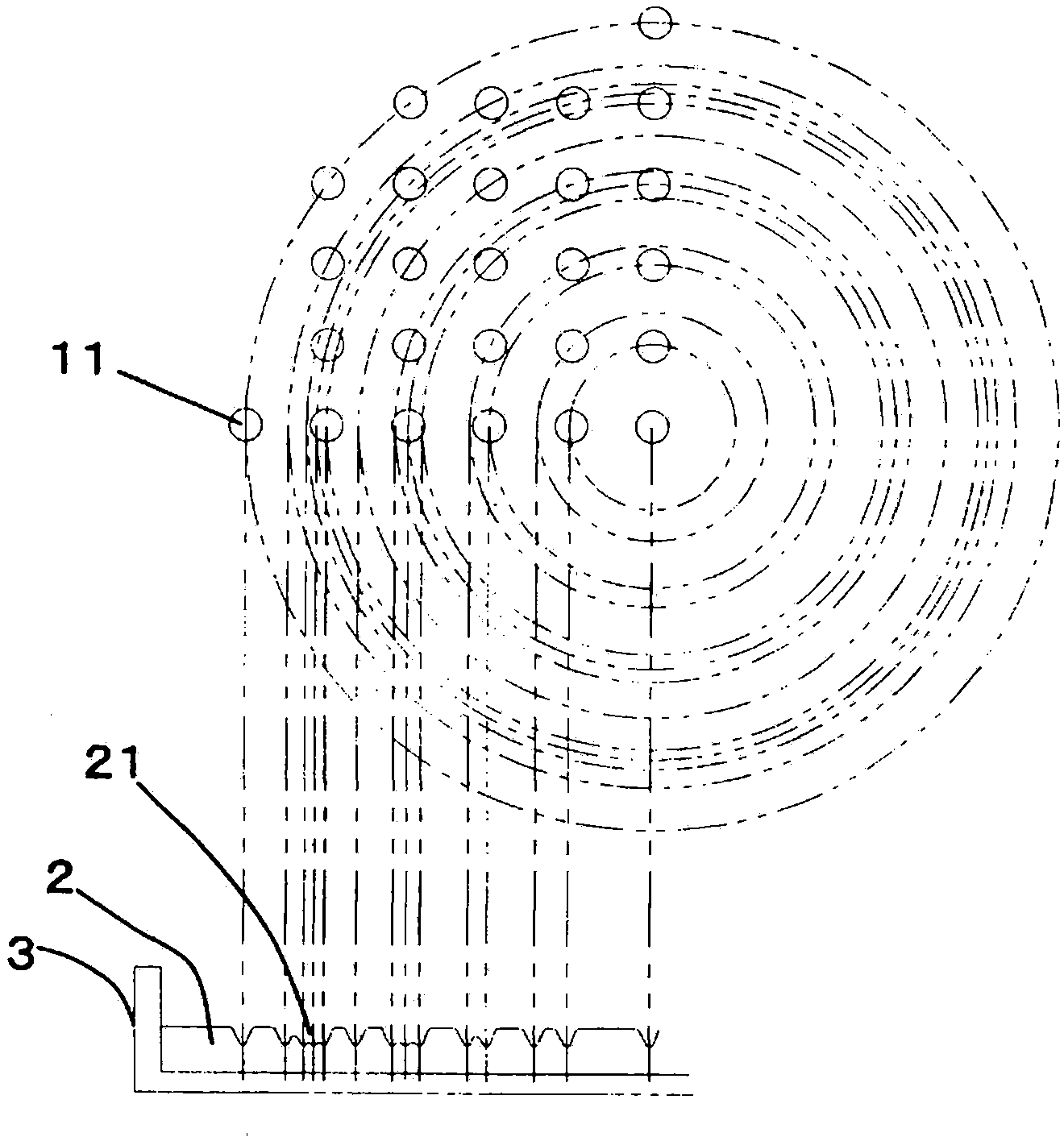

[0044] The airborne bacteria trap using the method of arranging the nozzle holes of the trapping nozzles of the airborne microbe trap is the same as the conventional airborne microbe trap, such as figure 2 As shown, nozzle holes 11 are arranged at regular intervals on the collecting nozzles 1 arranged at small intervals on the petri dish 3 containing the carrier 2 for attaching the airborne bacteria.

[0045] Furthermore, the petri dish 3 is rotated around the rotation shaft 4 by a motor (not shown).

[0046]And, when using this airborne bacteria trapping device to capture airborne bacteria, the petri dish 3 containing the carrier 2 is rotated, and the air sucked from the nozzle hole 11 formed on the capture nozzle 1 is sucked by the inertial metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com