Air spring auxiliary chamber with variable air volume

An air spring and additional air chamber technology, which is applied in the field of vehicle air suspension systems, can solve the problems that the volume of the additional air chamber cannot be adjusted quickly, the air spring stiffness has a small variation range, and the air spring variation range has been increased, so as to improve driving stability Sex and ride comfort, eliminate inconvenience, effect of large stiffness variation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

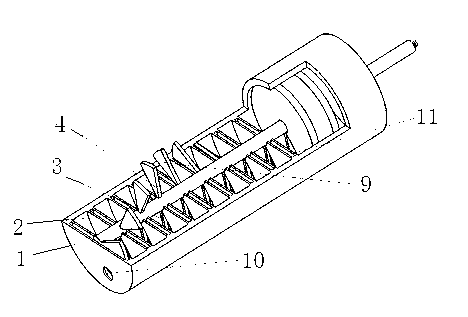

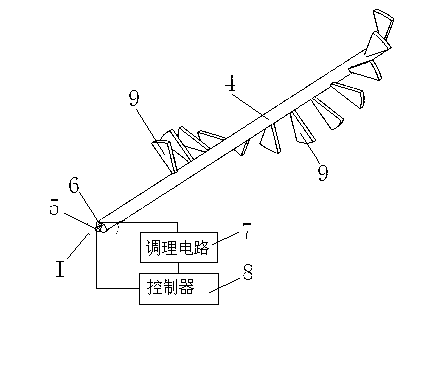

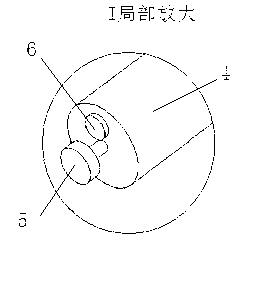

[0013] Such as figure 1 , 2 , 4, the main part of the present invention is a cylindrical cylinder 1 and the internal structure of the cylinder 1, in the cylindrical cylinder 1, there are n dividing plates 2 coaxially fixed on the inner wall of the cylinder 1, the n A partition 2 divides the inner chamber of the cylinder 1 into n small chambers in the axial direction. The central shaft 4 stretches into the cylinder body 1 from the outside of one end of the cylinder body 1 and is fixed on the other end of the cylinder body 1, and the central shaft 4 passes through the central holes of n dividing plates 2 in the cylinder body 1. A circular through hole 10 is processed on the other end surface of the cylinder body 1, and the circular through hole 10 communicates the additional air chamber with the main air chamber through a pipeline. Wherein, the first partition 2 is closely attached to the other end surface of the cylinder body 1 .

[0014] There is a fan-shaped through-hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com