Volume variable air spring auxiliary chamber experiment device and method

An additional air chamber and air spring technology, applied in railway vehicle testing, vehicle suspension/shock absorber testing, liquid/vacuum measurement for liquid tightness, etc. Slowness, unfavorable arrangement of air suspension, etc., to achieve the effect of simple structure, improved driving stability and riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

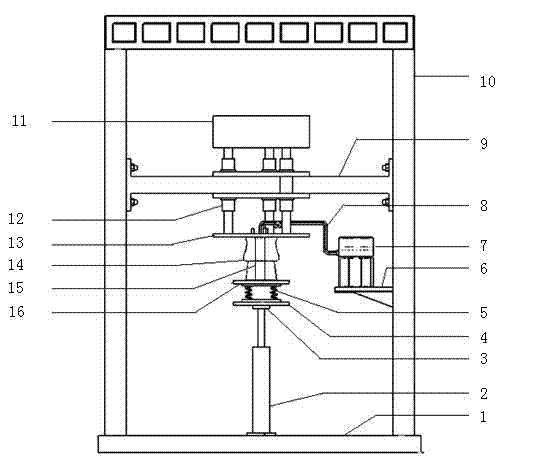

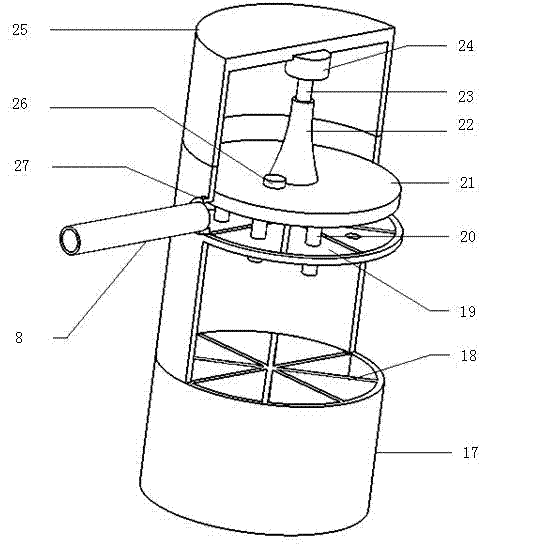

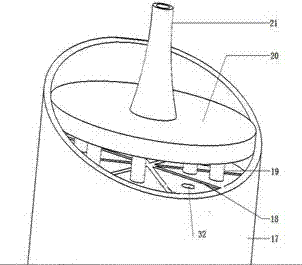

[0014] see figure 1 , the test device of the present invention adopts a gantry frame structure, and the columns 10 of the gantry frame are vertically fixed on both sides of the base 1 by bolts, and the oil cylinder 2 is vertically fixed by bolts in the middle of the base 1, and the upper end of the oil cylinder 2 is connected by bolts to excite vibration. The head 3 and the upper end of the exciting head 3 are connected to the small connecting tray 4 through bolts, the lower end of the coil spring 5 is connected to the small connecting tray 4, and the upper end is connected to the unsprung mass counterweight 16 . The shock absorber 15 and the main air chamber 14 are sequentially connected between the unsprung mass counterweight 16 and the large connection tray 13 by bolts. The main air chamber 14 of the air spring is connected to the additional air chamber 7 through the conduit 8 , the additional air chamber 7 is fixedly placed on the support plate 6 , and the support plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com