Peak Hold Drive Method

A technology of peak hold and driving method, applied in the direction of improving amplifiers to reduce the influence of noise, etc., can solve problems such as inability to achieve precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

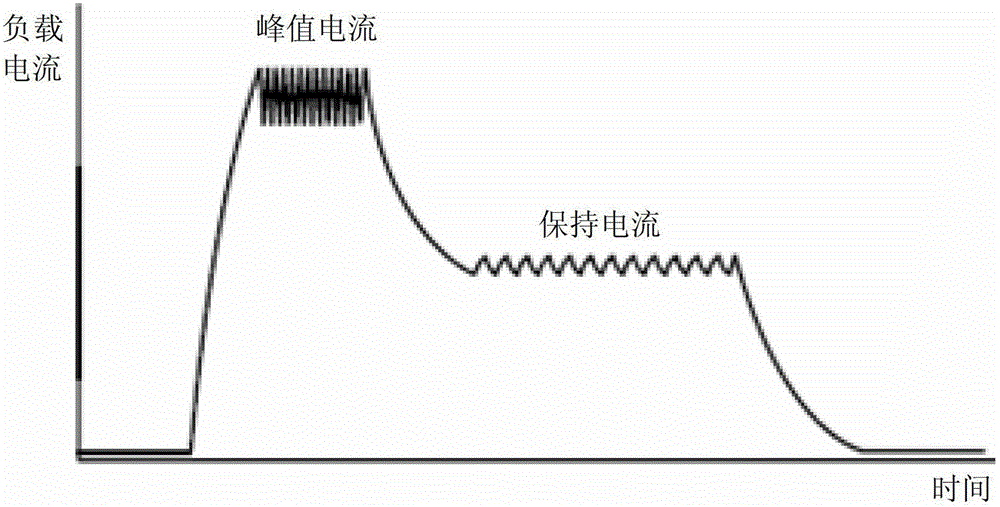

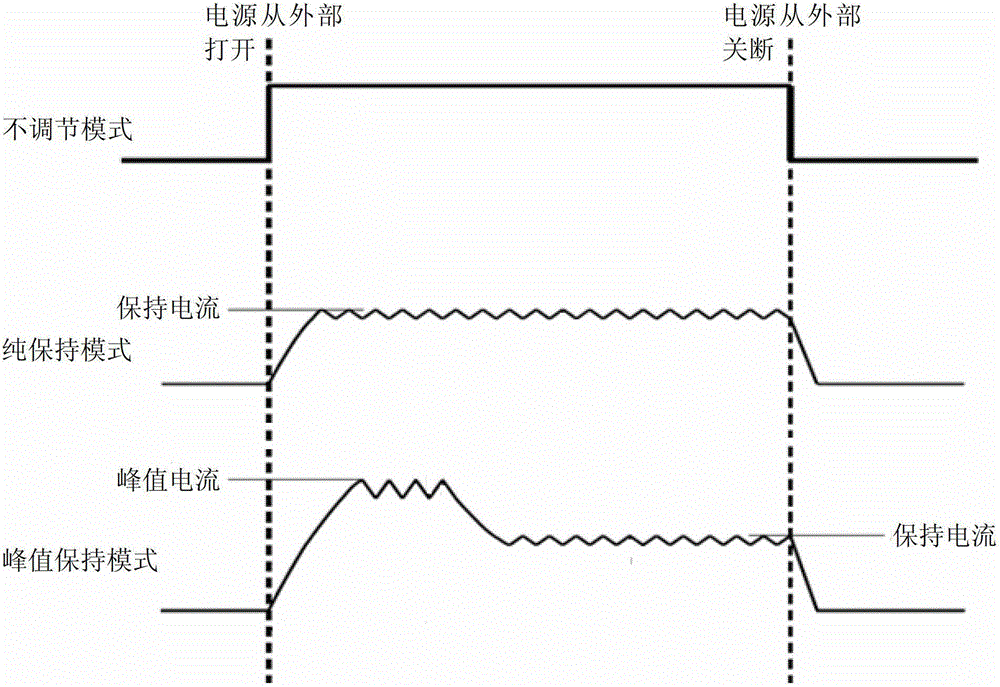

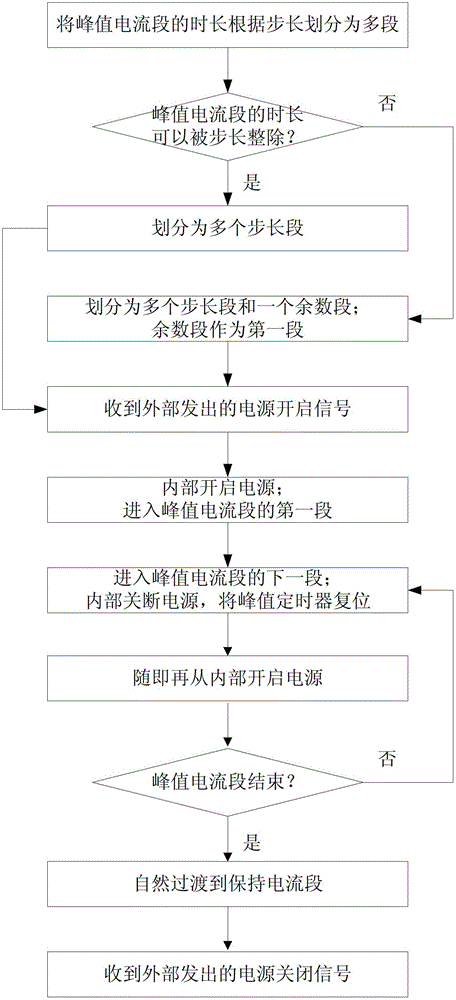

[0023] see image 3 , the peak-hold driving method of the present application will be described in detail below with a specific embodiment. Figure 4 Yes image 3 The schematic diagram of the load current variation with time of the embodiment, Figure 5 Yes image 3 Experimental verification waveform diagram of the embodiment.

[0024] Assume that an inductive load requires to maintain the peak current value for 8ms, and then reduce to the holding current. However, in the existing peak hold driving device, the timing time of the peak timer can be set to 0.6ms, 0.9ms, 1.2ms.

[0025] According to the method described in this application, for example, 1.2ms is first set as the step size, and then the duration of the desired peak current value (ie, the duration of the peak current segment) of 8ms is divided into multiple segments according to the step size of 1.2ms. Since 8ms cannot be divisible by 1.2ms, the division result is composed of six step segments with a duration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com